Non-crucible growing method for magneto-optic rear earth ferrite crystal

A growth method, ferrite technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of crucible corrosion environment, high growth temperature, easy occurrence of magnetoplumbite, etc., to achieve the elimination of crucible pollution, growth Simple preparation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

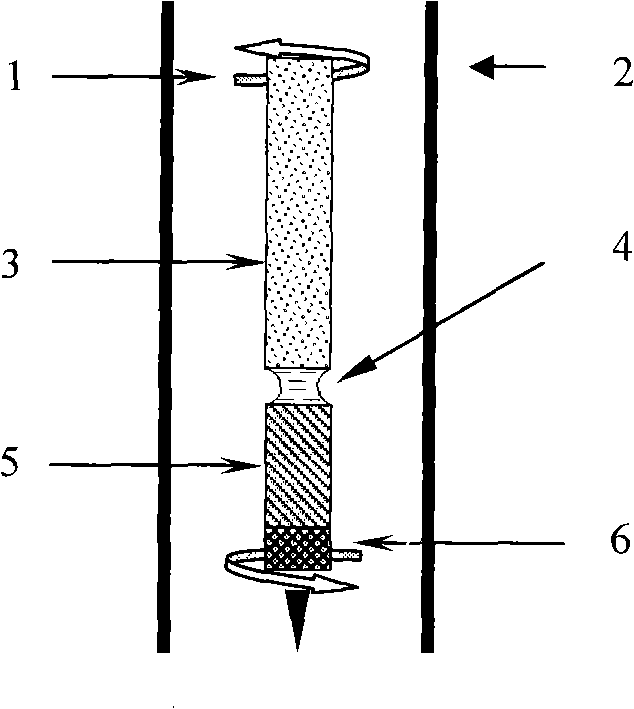

Method used

Image

Examples

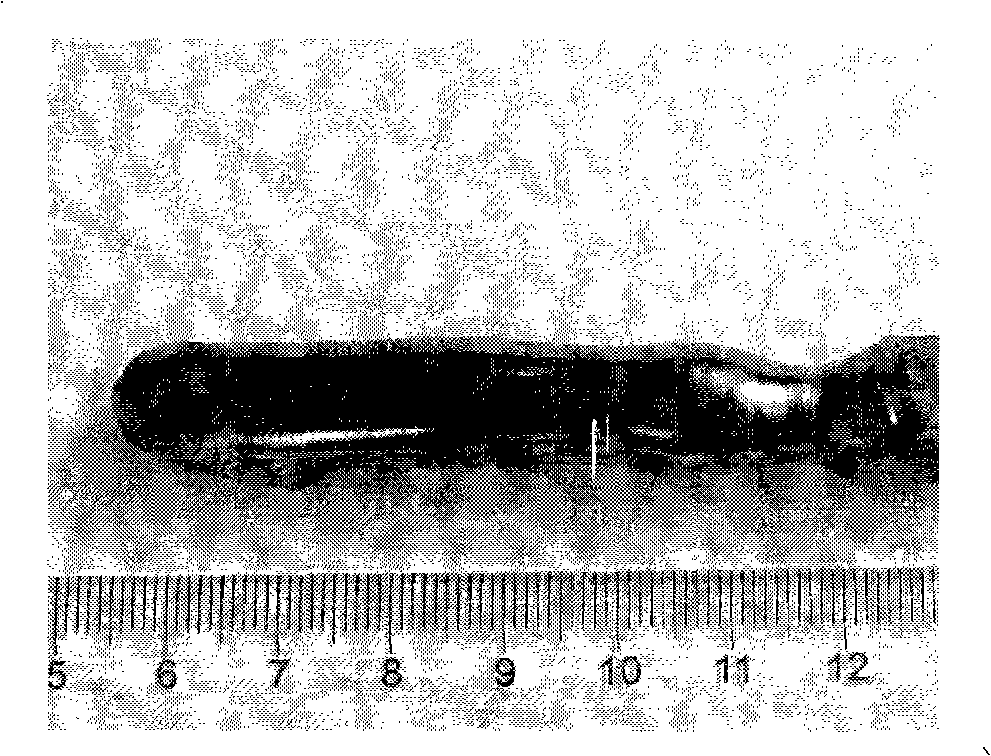

Embodiment 1

[0021] Y with a molar ratio of 1:1 2 o 3 with Fe 2 o 3 After weighing and mechanically mixing evenly, pre-fire at 1000°C for 10h, press it into a rod shape under 250MP isostatic pressure, sinter in a muffle furnace at 1500°C for 24h, put it into a crucible-free single crystal growth furnace, and heat it with laser focus. Crystals were grown in an air atmosphere. Growth rate: 5mm / h, raw material rod rotation speed: 10rpm, seed crystal rotation speed: 10rpm. After the rod is completely crystallized, the temperature is slowly lowered, and the crystal is taken out. The crystal was annealed at 1000°C for 30 hours in an air atmosphere to obtain a crystal. After testing, the crystal structure was complete and it was pure YFeO 3 phase, there are no other impurity phases, and the crystal quality is good.

Embodiment 2

[0023] Y with a molar ratio of 1:1.08 2 o 3 with Fe 2 o 3 Weigh, mechanically mix evenly, pre-fire at 900°C for 15h, use 200MP isostatic pressing to form a primary rod with a diameter of 16mm, then sinter in a muffle furnace at 1600°C for 20h, and put it into a crucible-free single crystal growth furnace , using resistance heating, air atmosphere growth. The growth rate is 6 mm / h, the rotation speed of the rod is 5 rpm, and the rotation speed of the seed crystal is 15 rpm. After the crystal growth was completed, the temperature was slowly lowered to room temperature, and the crystal was taken out. The crystal was annealed at 1100°C for 36 hours in an air atmosphere to obtain high-quality YFeO without cracks 3 crystals.

Embodiment 3

[0025] Tm with a molar ratio of 1:1.05 2 o 3 with Fe 2 o 3 After weighing and mixing uniformly, pre-fire at 950°C for 10h, press it into a rod shape under 150MP isostatic pressure, sinter in a muffle furnace at 1500°C for 24h, put it into a single crystal growth furnace, and heat it with resistance. TmFeO grown in 3 crystals. The growth rate is 8mm / h, the rotation speed of the material rod and the seed crystal are both 10rpm, and the temperature is slowly cooled to room temperature after the material rod is completely crystallized to obtain TmFeO 3 crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com