Method for determining vanadium in vanadium nitrogen alloy

A measurement method, the technology of vanadium-nitrogen alloy, is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve inaccurate results, unspecific acidity control values, and additional Low volume and other issues, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

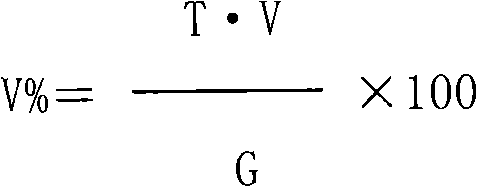

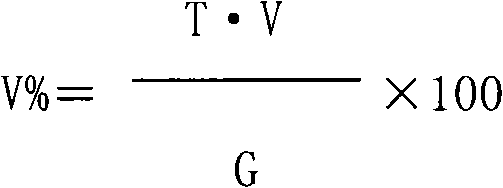

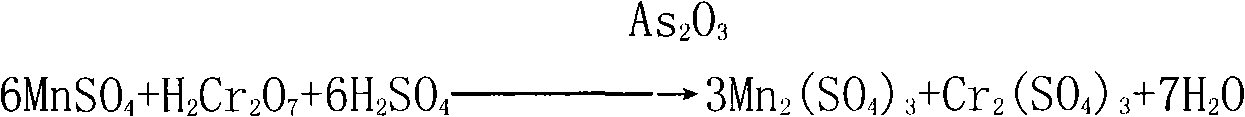

[0054] Take vanadium-iron alloy standard sample (numbering is 69-44) 0.2000g in the Erlenmeyer flask of 500ml, add H 2 SO 4 (1+4) 50ml, put it on the electric furnace at low temperature and heat to dissolve, after large bubbles appear, add 2-3ml of nitric acid to oxidize, add H 3 PO 4 (Concentrated) 5ml continues to heat on the electric stove until sulfuric acid fumes are emitted for 2-3 minutes, remove it and cool slightly, add 50ml of water, and cool to room temperature. join (NH 4 ) 2 Fe(SO 4 ) 2 Standard solution 2ml, shake well, let it stand for 2min, add KMnO dropwise 4 Solution until the test solution is stable red and does not fade. Stand for 2min, add urea solution 10ml, drop NaNO 2 solution until the red color disappears, and add 2 drops of NaAsO 2 After 5ml of the solution, add 2 drops of NaNO 2 Solution, put it aside for 2min, add 3 drops of CrV indicator, and immediately titrate with ferrous ammonium sulfate standard solution until the test solution chan...

Embodiment 2

[0059] Take vanadium iron alloy standard sample (numbering is 50-A-2) 0.2000g in the Erlenmeyer flask of 500ml, add H 2 SO 4 (1+4) 50ml, put it on the electric furnace at low temperature and heat to dissolve, after large bubbles appear, add 2-3ml of nitric acid to oxidize, add H 3 PO 4 (Concentrated) 5ml continues to heat on the electric stove until sulfuric acid fumes are emitted for 2-3 minutes, remove it and cool slightly, add 50ml of water, and cool to room temperature. join (NH 4 ) 2 Fe(SO 4 ) 2 Standard solution 2ml, shake well, let it stand for 2min, add KMnO dropwise 4 Solution until the test solution is stable red and does not fade. Stand for 2min, add urea solution 10ml, drop NaNO 2 solution until the red color disappears, and add 2 drops of NaAsO 2 After 5ml of the solution, add 2 drops of NaNO 2 solution, let it stand for 2 minutes, add 3 drops of CrV indicator, and immediately titrate with ferrous ammonium sulfate standard solution until the test solutio...

Embodiment 3

[0061] Take vanadium-nitrogen alloy sample (numbering is 1#) 0.2000g in the Erlenmeyer flask of 500ml, add H 2 SO 4 (1+4) 50ml, put it on the electric furnace at low temperature and heat to dissolve, after large bubbles appear, add 2-3ml of nitric acid to oxidize, add H 3 PO 4 (Concentrated) 5ml continues to heat on the electric stove until sulfuric acid fumes are emitted for 2-3 minutes, remove it and cool slightly, add 50ml of water, and cool to room temperature. join (NH 4 ) 2 Fe(SO 4 ) 2 Standard solution 2ml, after shaking well, let stand for 2min, add KMnO dropwise 4 Solution until the test solution is stable red and does not fade. Stand for 2min, add urea solution 10ml, drop NaNO 2 solution until the red color disappears, and add 2 drops of NaAsO 2 After 5ml of the solution, add 2 drops of NaNO 2 solution, let it stand for 2 minutes, add 3 drops of CrV indicator, and immediately titrate with ferrous ammonium sulfate standard solution until the test solution ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com