Method for manufacturing nanocrystalline thin-film device for ultraviolet detecting

A technology for ultraviolet detectors and thin-film devices, which is applied in the manufacture of semiconductor devices, electrical components, and final products. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

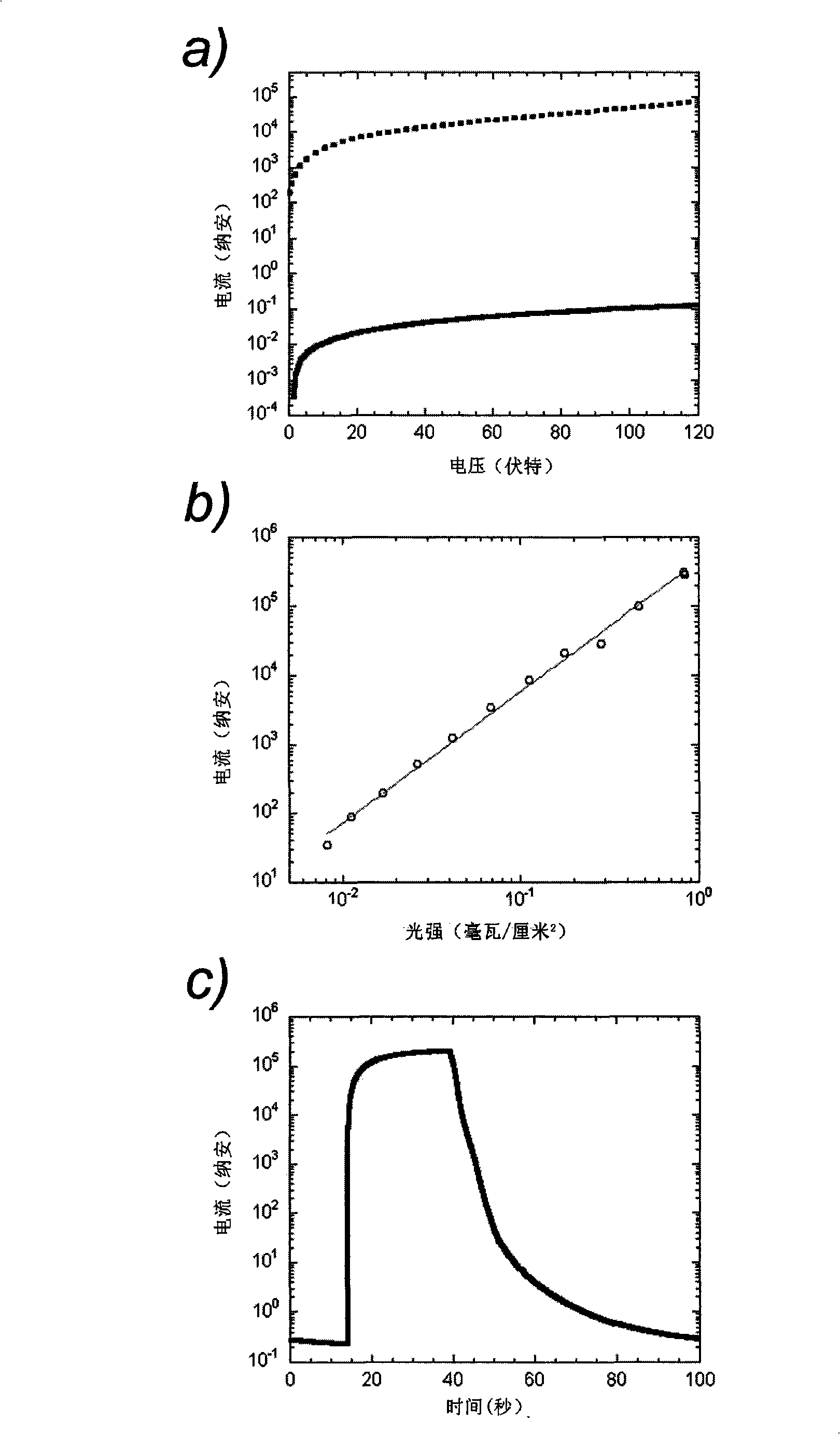

[0020] Dissolving ZnO nanocrystals in chloroform solvent to prepare a nanocrystal solution with a concentration of 50 mg / ml. The ZnO nanocrystal solution was spin-coated on the cleaned glass substrate by a spin-coating method to form a uniform film with a thickness of 100 nm. After annealing at 250°C for 20 minutes in air, a pair of T-shaped Ag electrodes with a spacing of 240 μm, a length of 3 mm, and a thickness of 60 nm were evaporated on the surface of the nanocrystalline film to prepare a nanocrystalline film device for ultraviolet detection. . For the test results of the device see figure 1 , with the following characteristics:

[0021] A. The dark current is extremely low, and the resistance at room temperature exceeds 1T (10 12 )Ω.

[0022] B. No response to light with a wavelength exceeding 400nm, that is, in the visible / infrared region.

[0023] C. The ultraviolet light guide has high sensitivity, at an intensity of 0.83mW / cm 2 Under the irradiation of 370nm ul...

Embodiment 2

[0028] The Mg-doped ZnO nanocrystals were dissolved in tetrahydrofuran solvent to prepare a nanocrystal solution with a concentration of 2 mg / ml. The ZnO nanocrystal solution was spin-coated on the cleaned SiO surface by spin coating method. 2 / Si substrate, a uniform thin film with a thickness of 10 nm was formed. After annealing at 350°C for 10 minutes in air, a pair of T-shaped Au electrodes with a distance of 240 μm, a length of 3 mm, and a thickness of 30 nm were evaporated on the surface of the nanocrystalline film to prepare a nanocrystalline film device for ultraviolet detection. .

Embodiment 3

[0030] Al-doped ZnO nanocrystals were dissolved in chloroform solvent to prepare a nanocrystal solution with a concentration of 100 mg / ml. The ZnO nanocrystal solution was spin-coated on the cleaned Si substrate by a spin-coating method to form a uniform film with a thickness of 200 nm. After annealing at 250°C for 30 minutes in air, a pair of T-shaped Cu electrodes with a distance of 240 μm, a length of 3 mm, and a thickness of 60 nm were evaporated on the surface of the nanocrystalline film to obtain a prototype of the ultraviolet detector. Nanocrystalline thin film devices used in ultraviolet detectors were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com