Chinese medicine kudzu root extract new drying technique method

A new technology and technology of extract, which is applied in the field of new drying process of traditional Chinese medicine kudzu root extract, can solve the problems of poor product quality and achieve the effect of short drying time, low moisture content and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

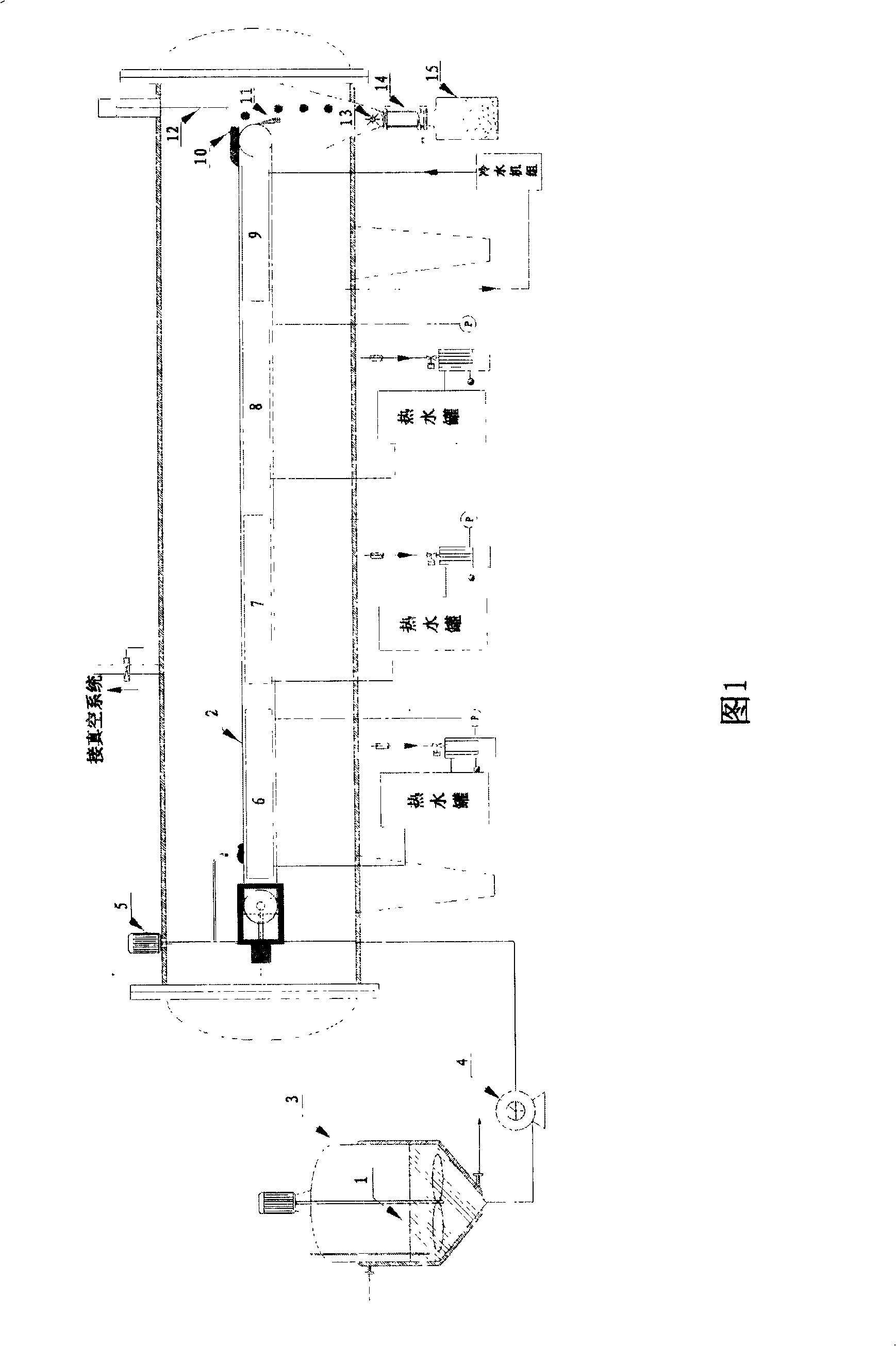

[0021] Referring to Figure 1, this embodiment will have a density of 1295kg / m 3 The kudzu root extract 1 (moisture content 40%) is preheated to 55 ℃ in feed tank 3 by screw feed pump 4 by the feeding speed of 6.0kg / h, is coated on conveyer belt by distributor 5 equably 2, the conveyor belt 2 runs at a speed of 6.0m / h, and the kudzu root extract moves through the heating section 6 (the temperature is 65° C.), the heating section 7 (the temperature is 60° C.), the heating section 8 ( temperature is 60° C.), and finally passes through the cooling section 9 (the temperature is 20° C.) to form a porous, loose cake-like dry matter 10 . When the dried material reaches the end of the equipment, it is scraped off from the conveyor belt 2 by the peeler 11, cut off by the cutting device 12, and then falls into the cage type pulverizer 13, and the pulverized dry material enters the product collection through the discharge device 14 tank 15. After analysis, the prepared kudzu root extrac...

Embodiment 2

[0023] The kudzu root extract density of this embodiment is 1362kg / m 3 (moisture content 35%), other operating conditions are with embodiment 1, and the moisture content of prepared kudzu root extract dry matter is 3.14%, and drying speed is 3.76kg / h. Production capacity is increased compared with embodiment 1.

Embodiment 3

[0025] The temperature of the heating section 6 of this embodiment is 80°C, the temperature of the heating section 7 is 75°C, the temperature of the heating section 8 is 65°C, the feed rate is 8.0kg / h, and other operating conditions are the same as in Example 1. The moisture content of the paste dried product was 2.96%, and the drying rate was 4.53kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com