Solid material with optical slicing characteristic and preparation method thereof

An optical limiting, solid-state technology, applied in the field of functional composite materials, can solve problems such as few research reports, and achieve the effect of high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

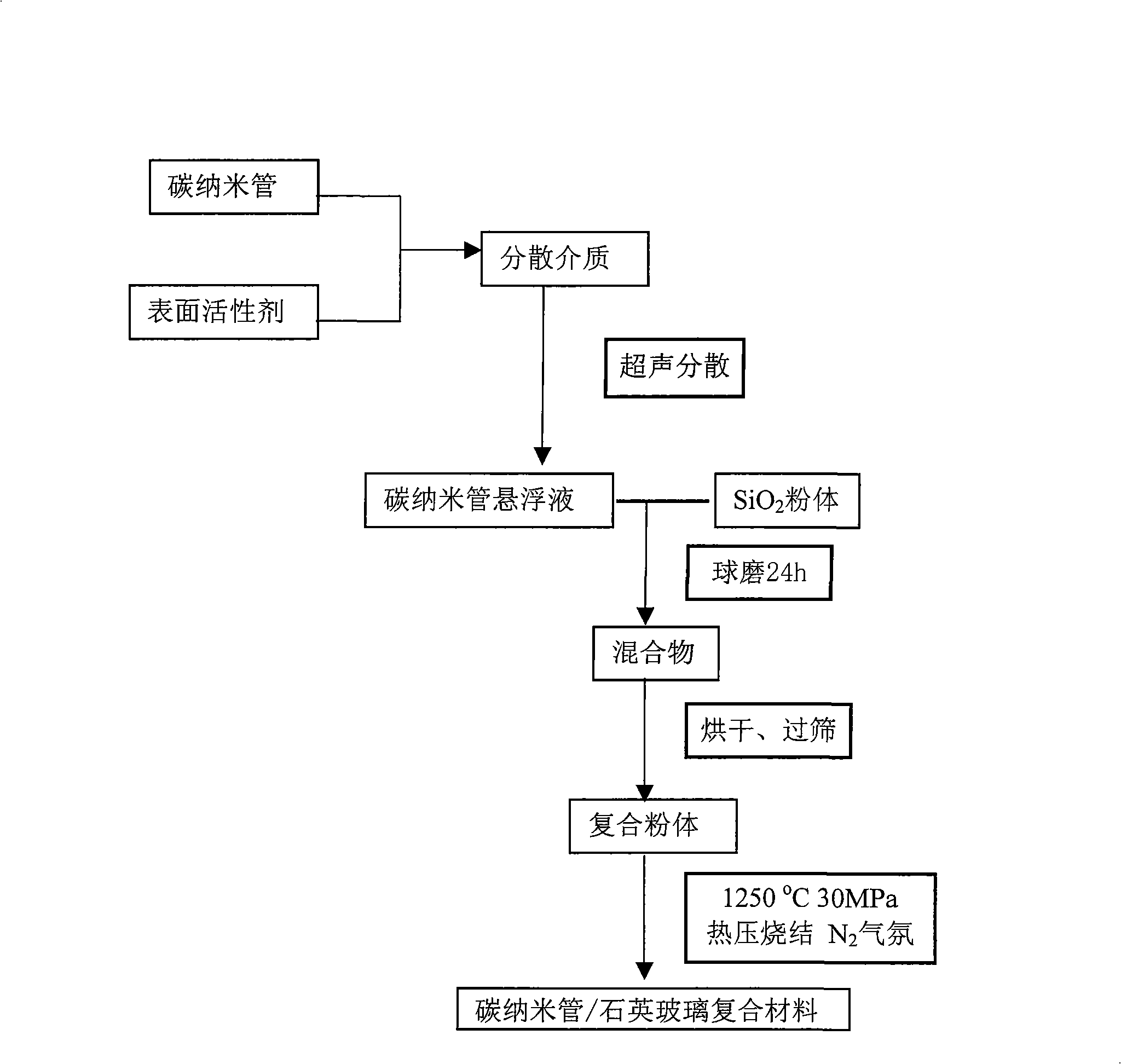

Method used

Image

Examples

Embodiment 1

[0038] A 0.02wt% carbon nanotube / quartz glass composite was prepared by direct ball milling.

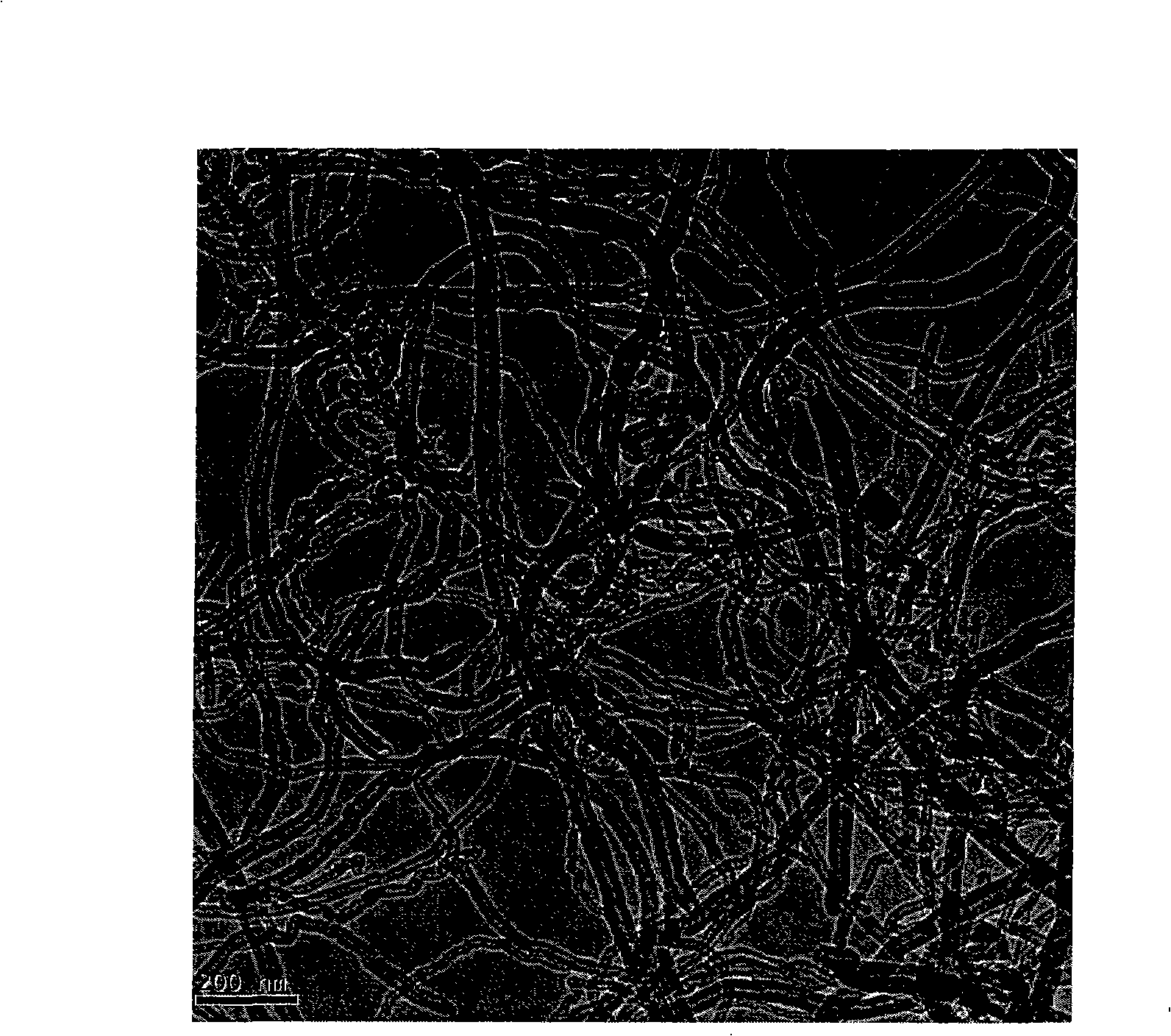

[0039] Carbon nanotubes are multi-walled carbon nanotubes (transmission electron micrographs of CNTs as shown in figure 2 shown).

[0040] 10 mg of carbon nanotubes, 0.1 g of cetyltrimethylammonium bromide (CTAB) and 60 ml of absolute ethanol were mixed and stirred for 5 minutes, and ultrasonically dispersed for 30 minutes to obtain a suspension of carbon nanotubes. The above carbon nanotube suspension, 50g silicon dioxide (SiO 2 ) powder and 150g agate balls were added into a 600mL ball mill jar, and the mixture was obtained after ball milling for 24h. Then the mixture was dried at 100°C for 5 h, and after passing through a 200-mesh sieve, a CNTs / SiO with a CNTs content of 0.02 wt% was obtained. 2 Powder. Finally, the prepared CNTs / SiO 2 Powder is added in graphite mould, under the pressure of 30Mpa and pure nitrogen (N 2 ) under a protective atmosphere, hot pressing and sint...

Embodiment 2

[0043] The 0.06wt% carbon nanotube / quartz glass composite was prepared by sol-gel method.

[0044] 30 mg of carbon nanotubes, 0.3 g of sodium dodecyl sulfate (SDS) and 80 mL of deionized water were mixed and stirred, and ultrasonically dispersed for 40 minutes to obtain a suspension of carbon nanotubes. At the same time, 216 mL of tetraethyl orthosilicate (TEOS), 250 mL of absolute ethanol and 200 mL of deionized water were mixed, stirred for 5 minutes, and then ultrasonicated at 40° C. for 30 minutes to hydrolyze the tetraethyl orthosilicate. Then, the suspension of carbon nanotubes was poured into the hydrolyzed tetraethyl orthosilicate, and while stirring magnetically, ammonia water with a concentration of 2.6M was added drop by drop until it gelled. The gel was washed 3 to 4 times with deionized water and 1 to 2 times with absolute ethanol, dried in an oven at 100°C for 12 hours, and then calcined in a muffle furnace at 500°C for 2 hours to obtain CNTs / SiO 2 Composite pow...

Embodiment 3

[0047] A 0.15wt% carbon nanotube / phosphate glass composite was prepared by direct ball milling.

[0048] 150 mg of carbon nanotubes, 0.6 g of dimethylformamide (DMF) and 120 ml of absolute ethanol were mixed and stirred for 5 minutes, and ultrasonically dispersed for 30 minutes to obtain a suspension of carbon nanotubes. The above carbon nanotube suspension, 30g B 2 o 3 , 20gCaO and 50g P 2 o 5 The mixture was obtained after ball milling for 30 h. Then the mixture was heated to 200 °C in a muffle furnace at a heating rate of 2 °C / min and kept for 4 h. After cooling, grind and pass through a 200-mesh sieve to obtain a carbon nanotube / phosphate glass powder with a carbon nanotube content of 0.15 wt%. Add the composite powder prepared in the graphite mould, under the pressure of 30Mpa and pure nitrogen (N 2 ) under a protective atmosphere, hot pressing and sintering at 1000° C. for 60 minutes to obtain a carbon nanotube / quartz glass composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com