Ordered mesoporous carbon/glass composite material with optical limiting property and preparation method

A technology of composite materials and mesoporous carbon, applied in optics, nonlinear optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

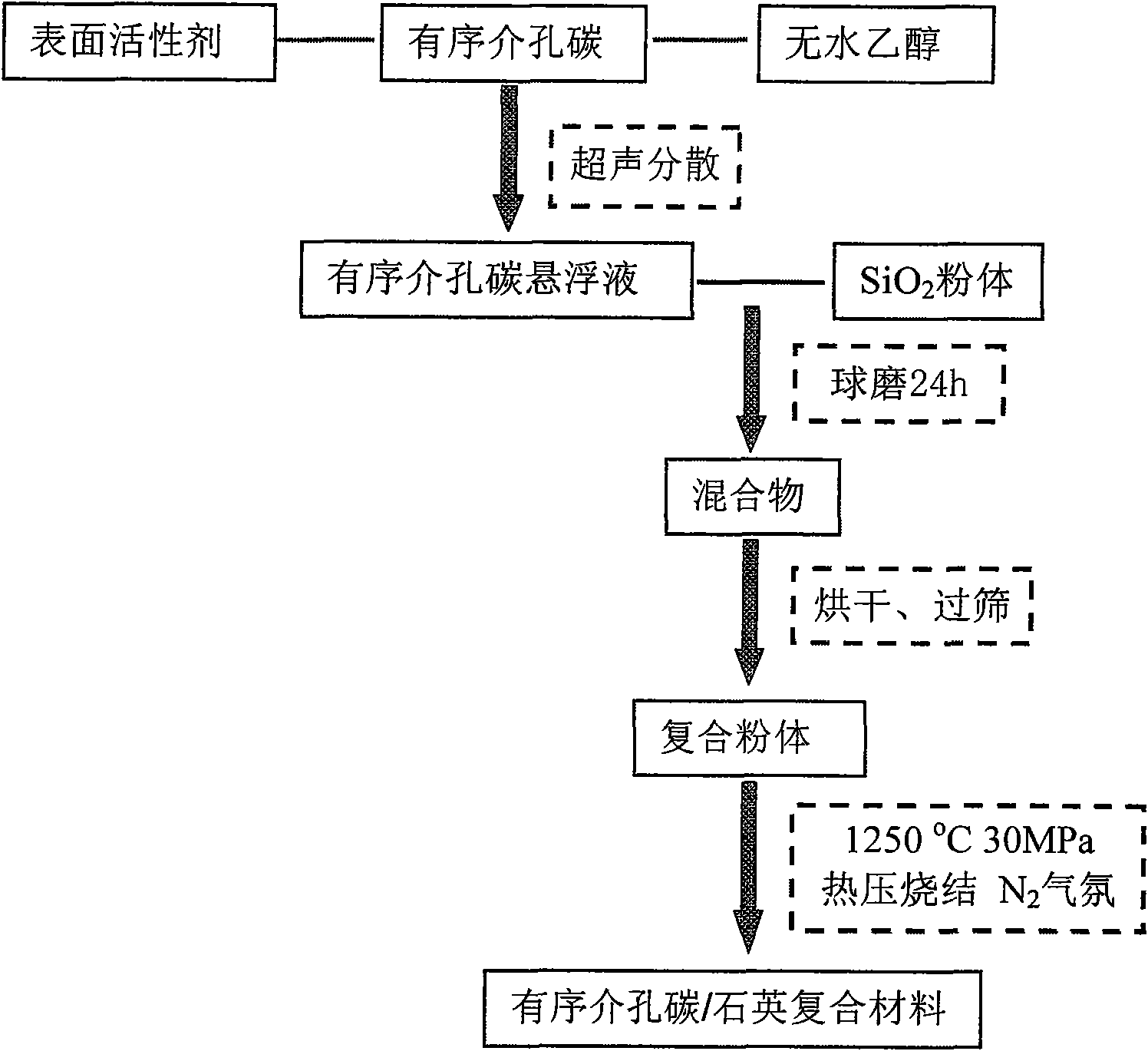

Method used

Image

Examples

Embodiment 1

[0032] 0.3wt% ordered mesoporous carbon / quartz glass composites were prepared by direct ball milling.

[0033] The ordered mesoporous carbon used in all the examples of the present invention is the template method (S.Jun, S.H.Joo, R.Ryoo, et al., J.Am.Chem.Soc., 122 (2000) 10712 -10713), the diameter of the ordered mesoporous carbon is about 6nm, and the length of the channel is micron.

[0034] According to the weight ratio of ordered mesoporous carbon, surfactant, solvent three is 3:2:960, get 0.15g ordered mesoporous carbon, 0.1g cetyltrimethylammonium bromide (CTAB) and 60ml Anhydrous ethanol was mixed and stirred for 5 minutes, and ultrasonically dispersed for 30 minutes to obtain an ordered mesoporous carbon suspension. The above ordered mesoporous carbon suspension, 50g of silicon dioxide (SiO 2 ) powder and 150g agate balls were added into a 600mL ball mill jar, and the mixture was obtained after ball milling for 24h. Then the mixture was dried at 100° C. for 10 h, ...

Embodiment 2

[0037] 0.70wt% ordered mesoporous carbon / quartz glass composite was prepared by sol-gel method.

[0038] According to the weight ratio of ordered mesoporous carbon, surfactant and solvent of 7:6:1600, take 350mg ordered mesoporous carbon, 0.3g sodium dodecyl sulfate (SDS) and 80mL deionized water and mix and stir , and ultrasonically dispersed for 40 minutes to obtain an ordered mesoporous carbon suspension. At the same time, 216 mL of tetraethyl orthosilicate (TEOS), 250 mL of absolute ethanol and 200 mL of deionized water were mixed, stirred for 5 minutes, and then ultrasonicated at 40° C. for 30 minutes to hydrolyze the tetraethyl orthosilicate. Then the ordered mesoporous carbon suspension was poured into the hydrolyzed tetraethyl orthosilicate, and while being magnetically stirred, ammonia water with a concentration of 2.6M was added drop by drop until it gelled. After the gel was washed 3-4 times with deionized water and 1-2 times with absolute ethanol, it was dried in ...

Embodiment 3

[0041] 0.5wt% ordered mesoporous carbon / alumina glass composites were prepared by homogeneous precipitation method.

[0042] According to the weight ratio of ordered mesoporous carbon and surfactant of 1:4, take 50 mg of ordered mesoporous carbon and 0.2 g of sodium dodecylbenzenesulfonate (SDBS) and add it to 1.85 L of 2M NH 4 HCO 3 In the aqueous solution, stir evenly, and ultrasonically disperse for 40 minutes. Then 1.85 L of 0.2M Al(NO 3 ) 2 The solution was dropped into the vigorously stirred mixed solution to obtain a precipitate. After the precipitate was filtered and dried, it was calcined in a muffle furnace at 500° C. for 2 hours to obtain a composite powder of alumina and ordered mesoporous carbon. Put the composite powder under the pressure of 30Mpa and pure nitrogen (N 2 ) under a protective atmosphere, hot-pressing and sintering at 1400° C., and holding for 30 minutes, an ordered mesoporous carbon / alumina glass composite material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com