Method for partially oxidizing sodium alginate

A technology for oxidizing sodium alginate and sodium alginate, which is applied in the field of biomedical materials, can solve the problems of excessive hydrophilicity, lack of cell recognition sites, and high price of sodium periodate, and achieves that the method is simple, easy to control, and easy to popularize. The effect of application, easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

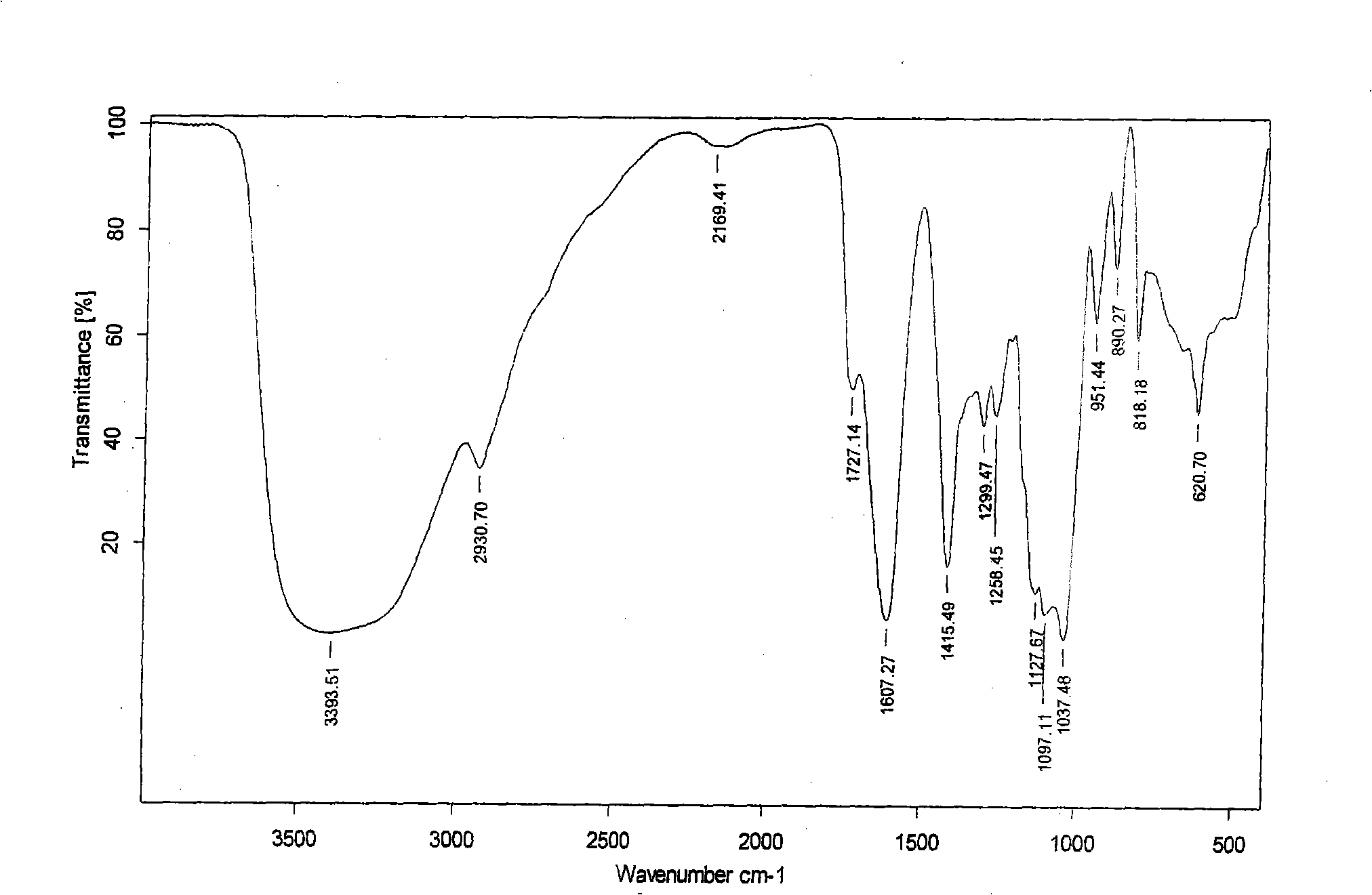

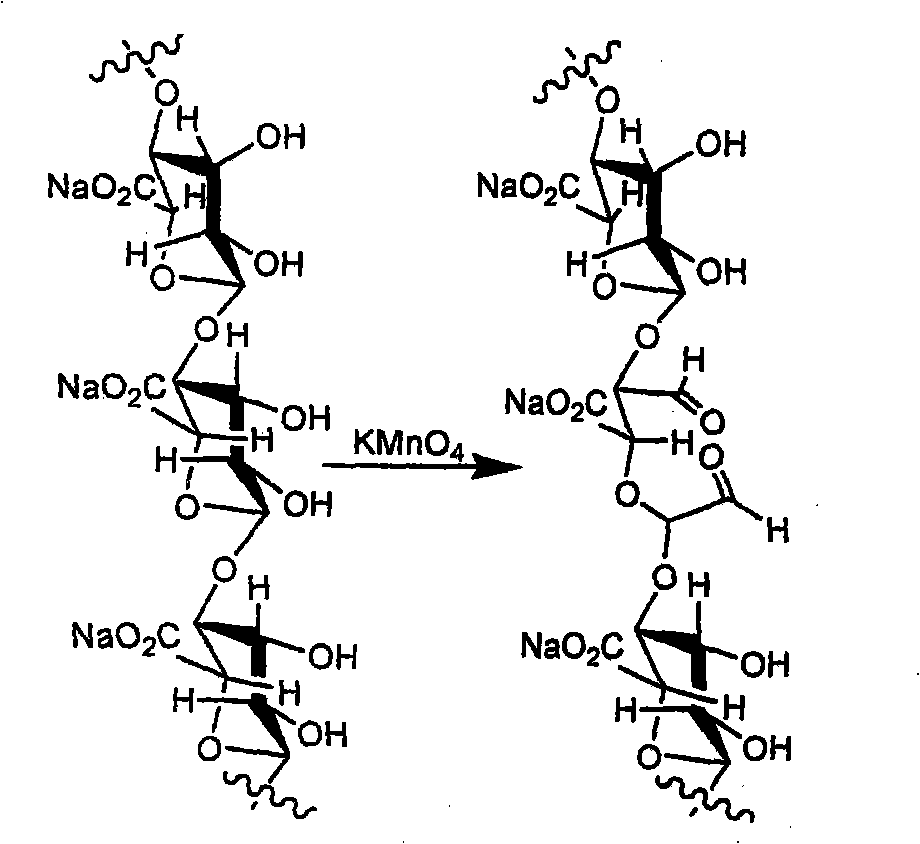

[0025] Weigh 1 g of sodium alginate and add it to 100 ml of deionized water, and stir magnetically until the sodium alginate is completely dissolved to obtain a 1% (w / v) sodium alginate solution. Weigh 1.5878g of potassium permanganate and put it in 100ml of distilled water, stir and boil. After the potassium permanganate is fully dissolved, let it stand in the dark for 6 days, and finally take the upper clear solution for calibration. The concentration of the potassium permanganate solution is 0.1227mol / L, stored in a brown bottle for later use. Add dropwise 0.5 ml of (1:5) aqueous sulfuric acid solution to the sodium alginate solution to adjust the pH value to 4, and stir the solution sufficiently. Then accurately measure 1.5ml of the above potassium permanganate solution and add it to the sodium alginate solution, stir and react at room temperature in the dark, and stop the oxidation reaction when the solution becomes colorless. In the solution after reaction, add 0.30g s...

Embodiment 2

[0027] Weigh 1 g of sodium alginate and add it to 100 ml of deionized water, and stir magnetically until the sodium alginate is completely dissolved to obtain a 1% (w / v) sodium alginate solution. Weigh 2.3756g of potassium permanganate and place it in 100ml of distilled water, stir and boil. After the potassium permanganate is fully dissolved, let it stand in the dark for 8 days. Finally, take the upper clear solution for calibration. The concentration of the potassium permanganate solution is 0.1671mol / L, stored in a brown bottle for later use. Add dropwise 0.5 ml of (1:5) aqueous sulfuric acid solution to the sodium alginate solution to adjust the pH value to 4, and stir the solution sufficiently. Then accurately measure 1.0ml of the above potassium permanganate solution and add it to the sodium alginate solution, stir and react at room temperature in the dark, and stop the oxidation reaction when the solution becomes colorless. In the solution after reaction, add 0.30g so...

Embodiment 3

[0029] Weigh 1 g of sodium alginate and add it to 100 ml of deionized water, and stir magnetically until the sodium alginate is completely dissolved to obtain a 1% (w / v) sodium alginate solution. Weigh 1.2683g of potassium permanganate and put it in 100ml of distilled water, stir and boil it. After the potassium permanganate is fully dissolved, let it stand in the dark for 4 days, and finally take the upper clear solution for calibration. The concentration of the potassium permanganate solution is 0.0848mol / L, stored in a brown bottle for later use. 0.3 ml of sulfuric acid aqueous solution (1:5) concentration was added dropwise to the sodium alginate solution to adjust the pH value to 3.5, and the solution was fully stirred. Then accurately measure 0.5ml of the above potassium permanganate solution and add it to the sodium alginate solution, stir and react at room temperature in the dark, and stop the oxidation reaction when the solution becomes colorless. Add 0.30g sodium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com