Drilling, spraying, injection integral enlarging anchor rod construction method

A technology of bolt construction and body expansion, which is applied in the directions of bolt installation, earthwork drilling, infrastructure engineering, etc., can solve the problems of collapsed holes, complicated and time-consuming construction processes, etc., and achieves good quality, strong construction operability, and economical Effects of slurry materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

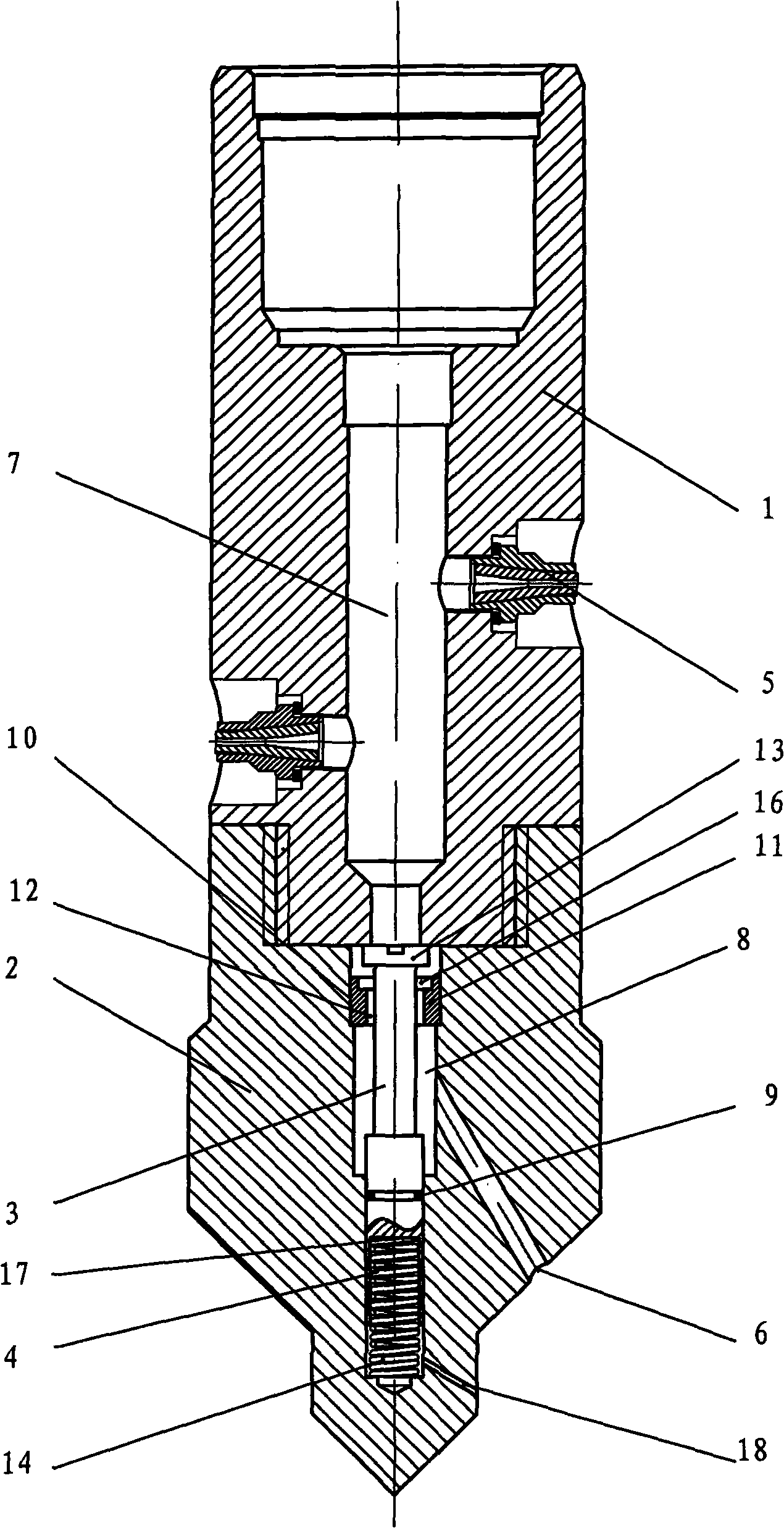

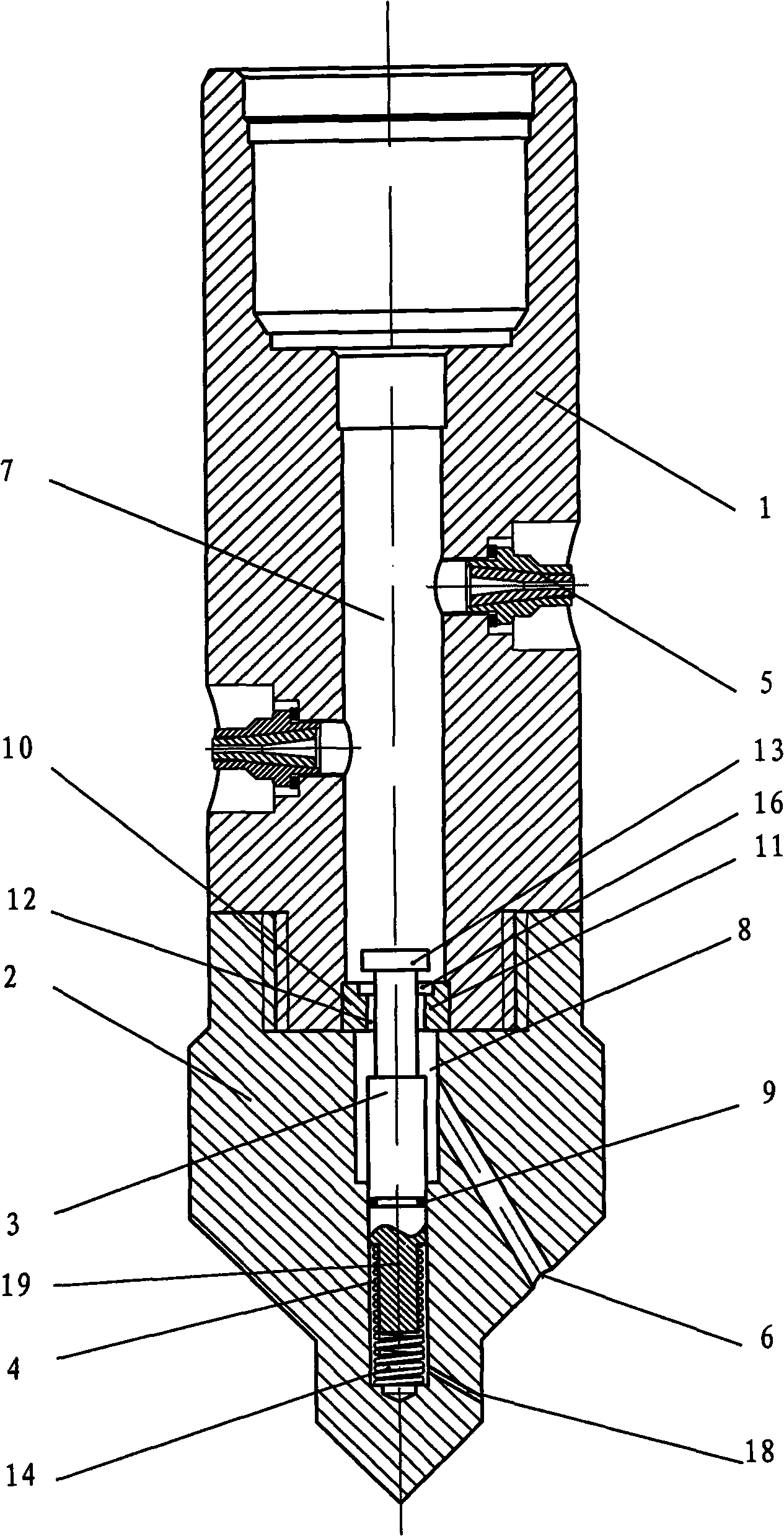

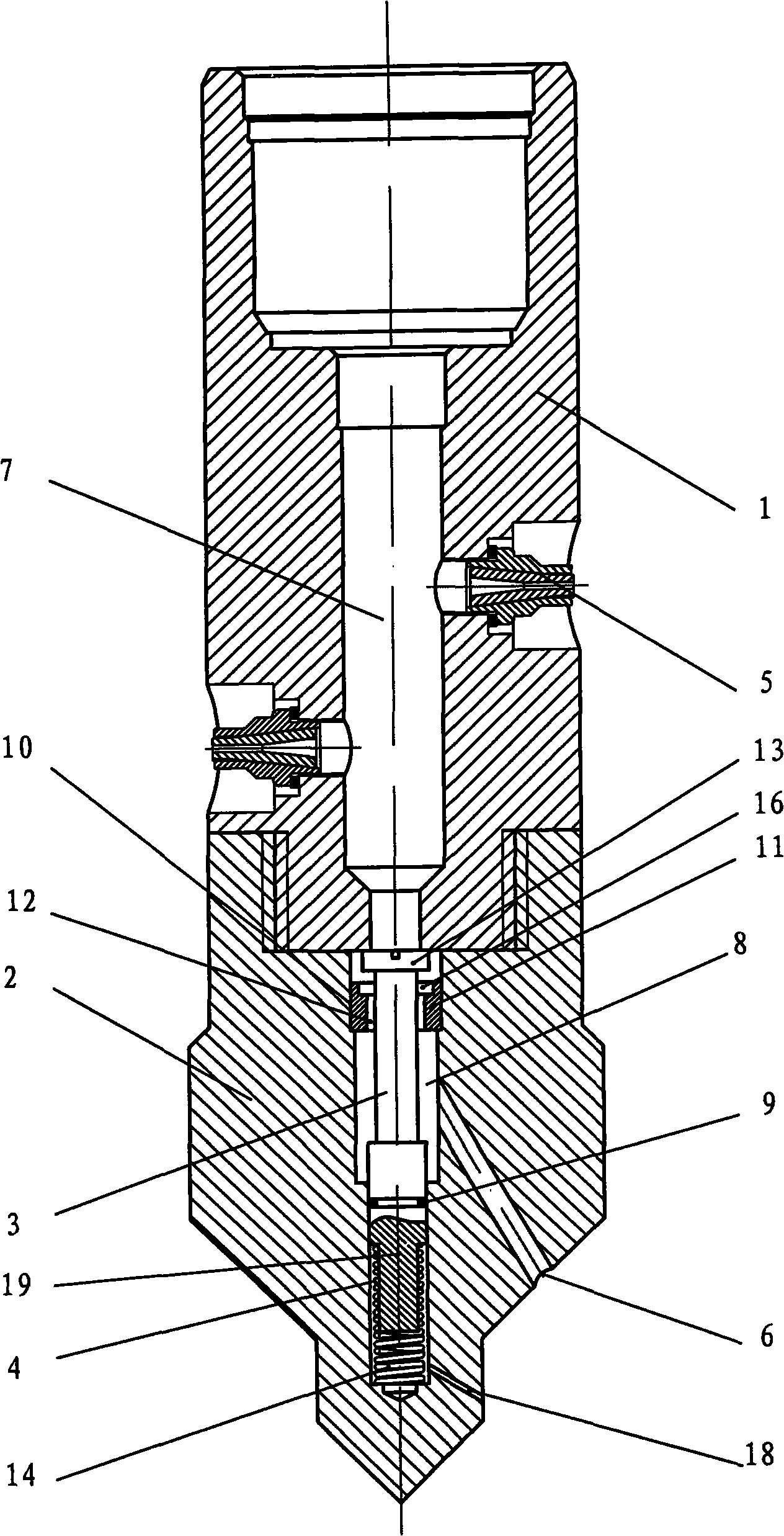

Image

Examples

Embodiment 1

[0031] The drilling-injection integrated expansion bolt construction method of the present invention comprises the following steps:

[0032] 1) The single-pipe drilling jet grouting drill bit equipped with auxiliary grouting holes that can be opened and closed by hydraulic control and the long drilling rig bolt drilling rig that can implement the single-pipe high-speed jet flow cutting process are used for drilling and forming holes. The length of the main drill frame of the rod drilling rig should be greater than 8m. During the drilling process, the drill bit is supplied with clean water or slurry at a pressure of 1-10MPa, and the clean water or slurry is injected from the auxiliary grouting hole of the drill bit until the drilling depth reaches the anchor. Hole design requirements, the drilling diameter range is 100-250mm;

[0033] 2) When the anchor hole drilled by the drill bit reaches the design depth, let the drill bit rotate at the innermost end of the anchor hole and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com