Method for preparing PVP-PEG-PLA shell-crosslinked nano micelle

A technology of micelle and shell layer, applied in the field of nano drug release carrier preparation, can solve the problems of long circulation time in vivo and narrow particle size distribution, and achieve the effects of large drug loading, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

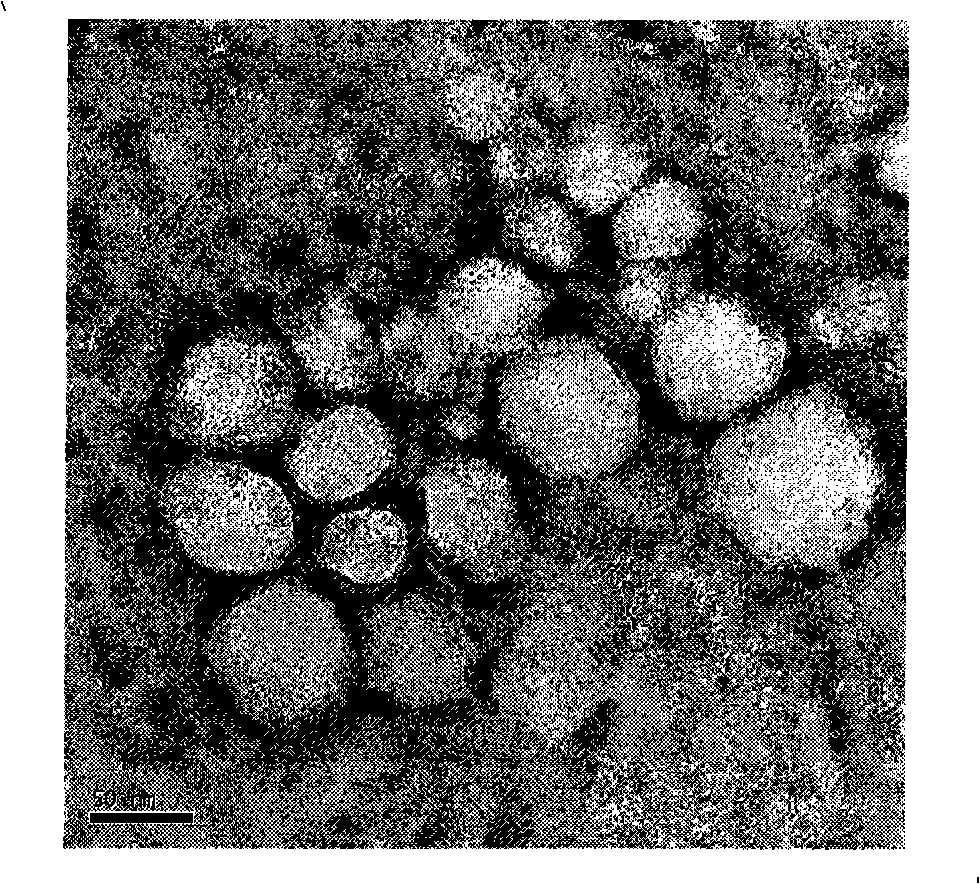

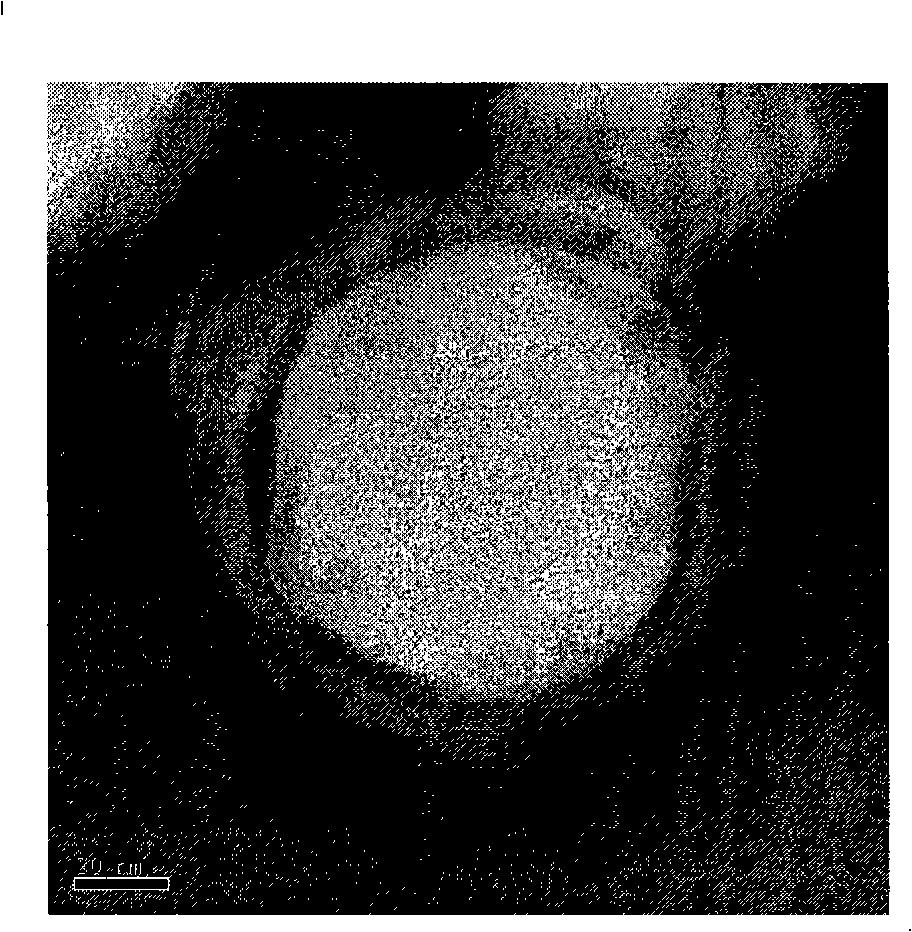

Image

Examples

Embodiment 1

[0021] Take 10 g of polyethylene glycol with a relative molecular mass of 400, add 30 mg of hydroquinone into the reactor, pass nitrogen gas under ice-bath conditions, add 2.5 g of methacryloyl chloride dropwise, and stir at 150 rpm for 24 hours to obtain polyethylene glycol For the crude product of monomethacrylate, dissolve the crude product in 40ml of deionized water, extract with 10ml of diphenyl ether, and then extract the obtained aqueous phase with 50ml of a mixture of 35.5ml of dichloromethane and 12.5ml of n-hexane , the organic solvent was distilled off to obtain polyethylene glycol monomethacrylate with a yield of 65%.

[0022] Take 4g of polyethylene glycol monomethacrylate, 1g of lactide and 1mg of stannous octoate into the reactor, and react in an anaerobic vacuum at 140°C for 24 hours. The obtained polymer is dissolved in chloroform and precipitated with petroleum ether to obtain The polyethylene glycol monomethacrylate-polylactic acid diblock copolymer has a pr...

Embodiment 2

[0026] Take 15g of polyethylene glycol with a relative molecular mass of 600, add 35mg of hydroquinone into the reactor, pass nitrogen gas under ice-bath conditions, add 2.5g of methacryloyl chloride dropwise, and stir for 24 hours at 150 rpm to obtain polyethylene glycol For the crude product of monomethacrylate, the crude product was dissolved in 60ml of deionized water, extracted with 15ml of diphenyl ether, and the obtained aqueous phase was re-extracted with 80ml of a mixture of 60ml of dichloromethane and 20ml of n-hexane, evaporated The organic solvent was removed to obtain polyethylene glycol monomethacrylate with a yield of 68.4%.

[0027] Take 4g of polyethylene glycol monomethacrylate, 2g of lactide and 2mg of stannous octoate into the reactor, and react in an anaerobic vacuum at 140°C for 24 hours. The obtained polymer is dissolved in chloroform and precipitated in petroleum ether to obtain The polyethylene glycol monomethacrylate-polylactic acid diblock copolymer ...

Embodiment 3

[0031]Take 10 g of polyethylene glycol with a relative molecular mass of 400, add 30 mg of hydroquinone into the reactor, pass nitrogen gas under ice-bath conditions, add 2.5 g of methacryloyl chloride dropwise, and stir at 150 rpm for 24 hours to obtain polyethylene glycol For the crude product of monomethacrylate, dissolve the crude product in 40ml of deionized water, extract with 10ml of diphenyl ether, and then extract the obtained aqueous phase with 50ml of a mixture of 35.5ml of dichloromethane and 12.5ml of n-hexane , the organic solvent was distilled off to obtain polyethylene glycol monomethacrylate with a yield of 65%.

[0032] Take 4g of polyethylene glycol monomethacrylate, 0.8g of lactide and 0.8mg of stannous octoate into the reactor, and react in an anaerobic vacuum at 140°C for 24 hours, and the obtained polymer is dissolved in chloroform and precipitated in petroleum ether , to obtain polyethylene glycol monomethacrylate-polylactic acid diblock copolymer, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com