Cobalt group catalyst synthesized with fischer tropsch process, production method and application thereof

A cobalt-based catalyst, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

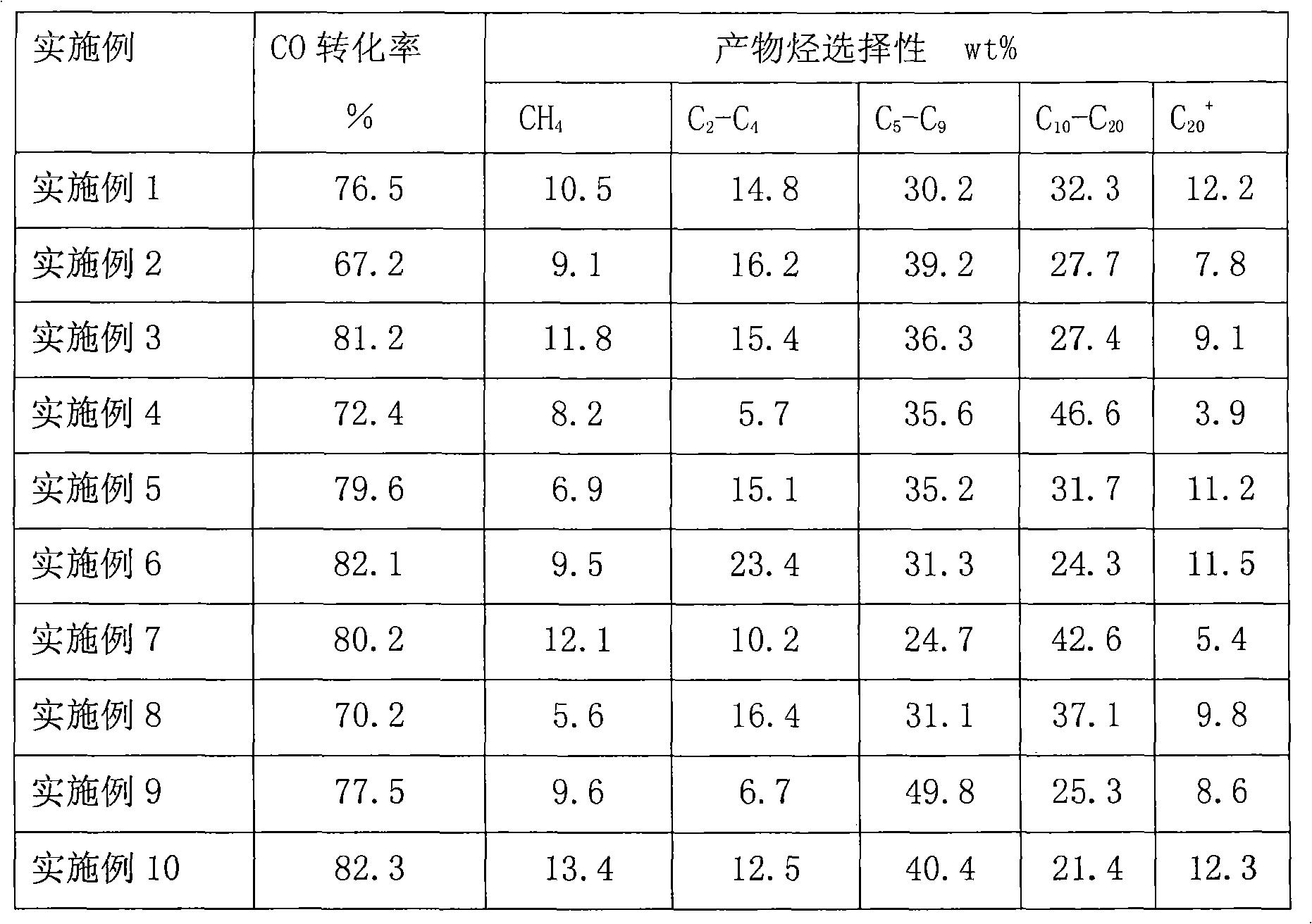

Examples

Embodiment 1

[0028] Weigh 7.4 grams of cobalt nitrate hexahydrate, dissolve it in 20 mL of deionized water, obtain a uniform solution, and use commercial silica gel as a carrier (specific surface area 176m 2 / g, average pore diameter 11.32nm), according to 15% Co / SiO 2 Catalyst composition Add 8.49 grams of commercial silica gel to the prepared solution, stir evenly, let it stand at room temperature for 90 hours, then dry it in a vacuum oven at 50°C for 100 hours, grind the dried solid thoroughly, and bake it in air at 600°C 3h, slowly heat up the calcined solid powder to 300°C for 60h reduction treatment in hydrogen atmosphere, reduction pressure 0.8MPa, reduction space velocity 100h -1 (V / V), naturally cool after the reduction, and switch to CO passivation gas passivation for 10 hours after the temperature drops to 250°C. The passivation pressure and space velocity are the same as the reduction process. The treated solid powder is compressed into tablets, and the 40-80 mesh components ...

Embodiment 2

[0031] Weigh 4.94 grams of cobalt nitrate hexahydrate, dissolve it in 20 mL of absolute ethanol to obtain a homogeneous solution, use ZSM-5 molecular sieve as a carrier (pore diameter is 0.51*0.55nm), and mix 9.03 grams of Add ZSM-5 molecular sieves to the prepared solution, stir evenly, let stand at room temperature for 12 hours, dry in a vacuum oven at 50°C for 100 hours, grind the dried solids thoroughly, and roast them in air at 300°C for 24 hours. The final solid powder is slowly heated to 400°C in a hydrogen atmosphere, the reduction pressure is 0.3MPa, and the reduction space velocity is 5000h -1 Under the conditions of (V / V), carry out the reduction treatment for 3h, and switch to CO and H with a volume percentage of CO of 99%. 2 The composition of the mixed gas is at 400°C, the reduction pressure is 0.3MPa, and the reduction space velocity is 5000h -1 Reduction treatment under (V / V) conditions for 3h, then natural cooling, switch to O after cooling down to 20°C 2 20...

Embodiment 3

[0034] Weigh 2.47 grams of cobalt nitrate hexahydrate, dissolve it in a mixed solution of 20 mL of methanol and ethanol to obtain a uniform solution, use the Y-type molecular sieve obtained by ion exchange as a carrier (average pore size is 0.74 nm), and use a 5% Co / HY catalyst composition Add 9.50 g of HY to the prepared solution, stir evenly, let it stand at room temperature for 90 hours, dry it in a drying oven at 120°C for 12 hours, grind the dried solid thoroughly, and roast it in air at 600°C for 3 hours. The solid powder is slowly heated to 300°C in a CO atmosphere, the reduction pressure is 0.0MPa, and the reduction space velocity is 1000h -1 Under (V / V) conditions, carry out the reduction treatment for 30 hours, and then switch to CO and H with a CO volume percentage of 1%. 2 The mixed gas is at 300°C, the reduction pressure is 0.0MPa, and the reduction space velocity is 1000h -1 Reduction treatment under (V / V) conditions for 30h, natural cooling until it drops to 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com