Method for synthesizing nano-HMS mesoporous molecular sieve in ion liquid

A technology of mesoporous molecular sieve and ionic liquid, applied in the field of preparation of HMS mesoporous molecular sieve, can solve the problems of difficult synthesis, few studies on the synthesis of nano-mesoporous molecular sieve, and no report on the synthesis of nano-HMS mesoporous molecular sieve, etc. The preparation process is simple and the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

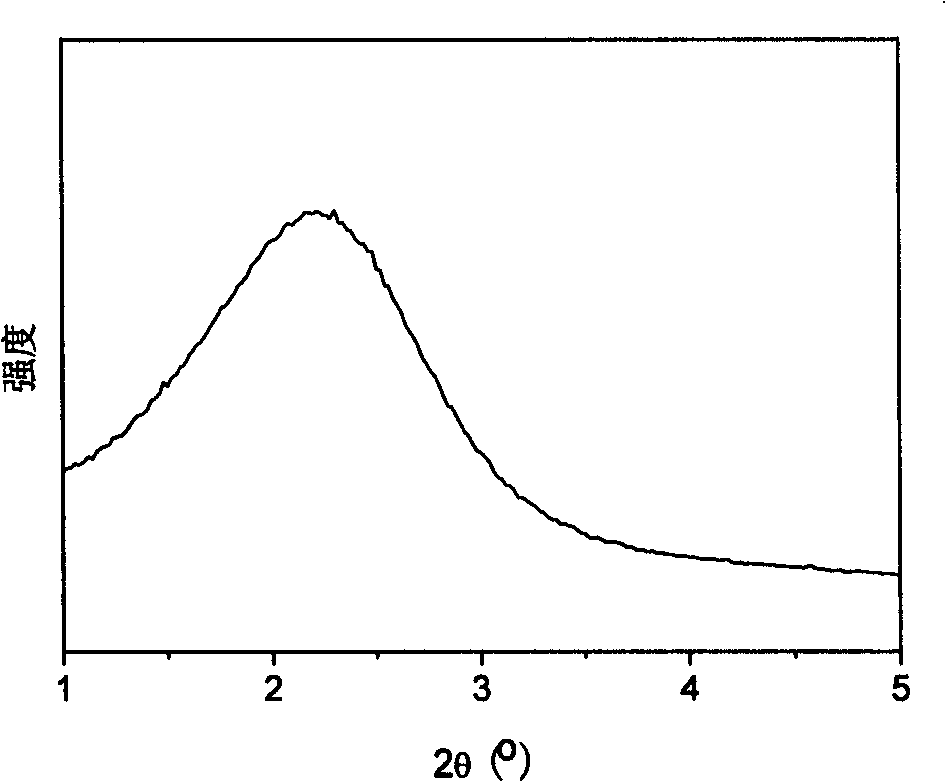

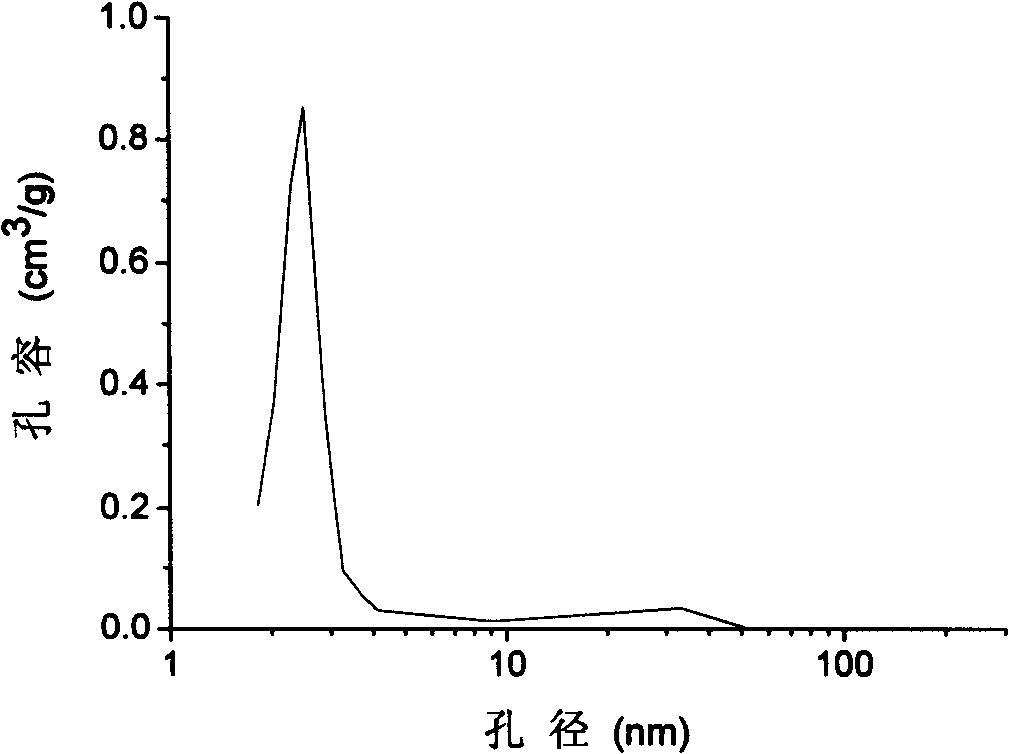

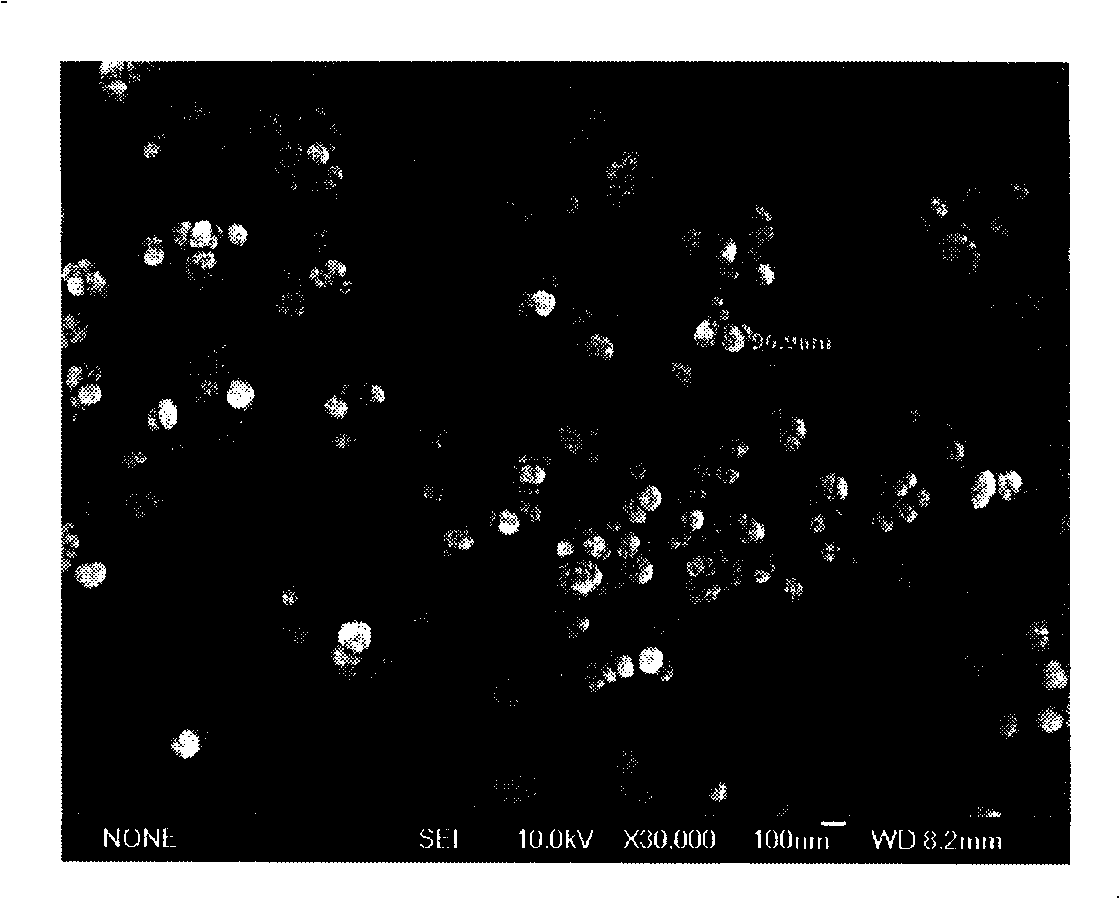

[0022] Example 1: 2.4023g DDA was mixed with 57.6ml deionized water, 18.2ml ethanol and 10.8g [BMIM][BF 4 ] mixed, stirred at room temperature for 30min, and then added dropwise 10g TEOS under stirring. The molar ratio of raw material liquid is TEOS: DDA: EtOH: H 2 O: [BMIM][BF 4 ]=1.0:0.27:6.5:66.7:1.0. After continuing to react at room temperature for 18 hours, perform suction filtration, wash with water, dry at 50°C for 24 hours, and finally bake at 550°C for 6 hours to remove template agent and ionic liquid to obtain HMS mesoporous molecular sieve. The analysis results show that the sample has a typical HMS mesoporous structure, see figure 1 and 2 , the synthesized molecular sieves are spherical particles with a diameter of about 60-100nm, uniform particle size and no agglomeration, see image 3 , the physical properties of the HMS mesoporous molecular sieve synthesized in this example are shown in Table 1.

Embodiment 2

[0023] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is: the mol ratio of raw material liquid is TEOS: DDA: EtOH: H 2 O: [BMIM][BF 4 ]=1.0:0.27:6.5:4.0:2.5. In this example, due to the small amount of water used, the ionic liquid is equivalent to the role of the solvent. The results show that nano-HMS mesoporous molecular sieves can also be synthesized at this time, see Figure 4 , its XRD pattern is also similar to Example 1. The particle size of the molecular sieve is about 50-80nm and does not agglomerate. The physical properties of the molecular sieve are shown in Table 1.

Embodiment 3

[0024] Example 3: 3.1294g HDA was mixed with 62.2ml deionized water, 18.2ml ethanol and 5.4g [BMIM][BF 4 ] mixed, stirred at room temperature for 30min, and then added dropwise 10g TEOS under stirring. The molar ratio of the raw material solution is TEOS: HDA: EtOH: H 2 O: [BMIM][BF 4 ]=1.0:0.27:6.5:72:0.5. After continuing to react at room temperature for 24 hours, suction filtration, washing with water, drying at 50°C for 24 hours, and finally calcination at 550°C for 6 hours to remove the template agent and ionic liquid, the XRD spectrum and pore size distribution curve of the prepared molecular sieve are the same as in Example 1 , 2 similar, the particle size is about 70 ~ 100nm, its physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com