Leadless solar battery silver paste and method for producing the same

A technology of solar cells and conductive silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as environmental pollution, high lead content, and non-compliance with environmental protection requirements. Achieve the effects of low ohmic contact resistance, strong adhesion, and high photoelectric conversion efficiency of batteries

Inactive Publication Date: 2008-09-24

EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

View PDF0 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the glass binder used in the conductive silver paste of solar cells is a bismuth-silicon-lead glass mixed powder. Although this glass powder has the advantages of low softening temperature and stable electrical properties, the system contains a relatively high proportion of lead. , the pollution to the environment is relatively large, and it does not meet the requirements of environmental protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

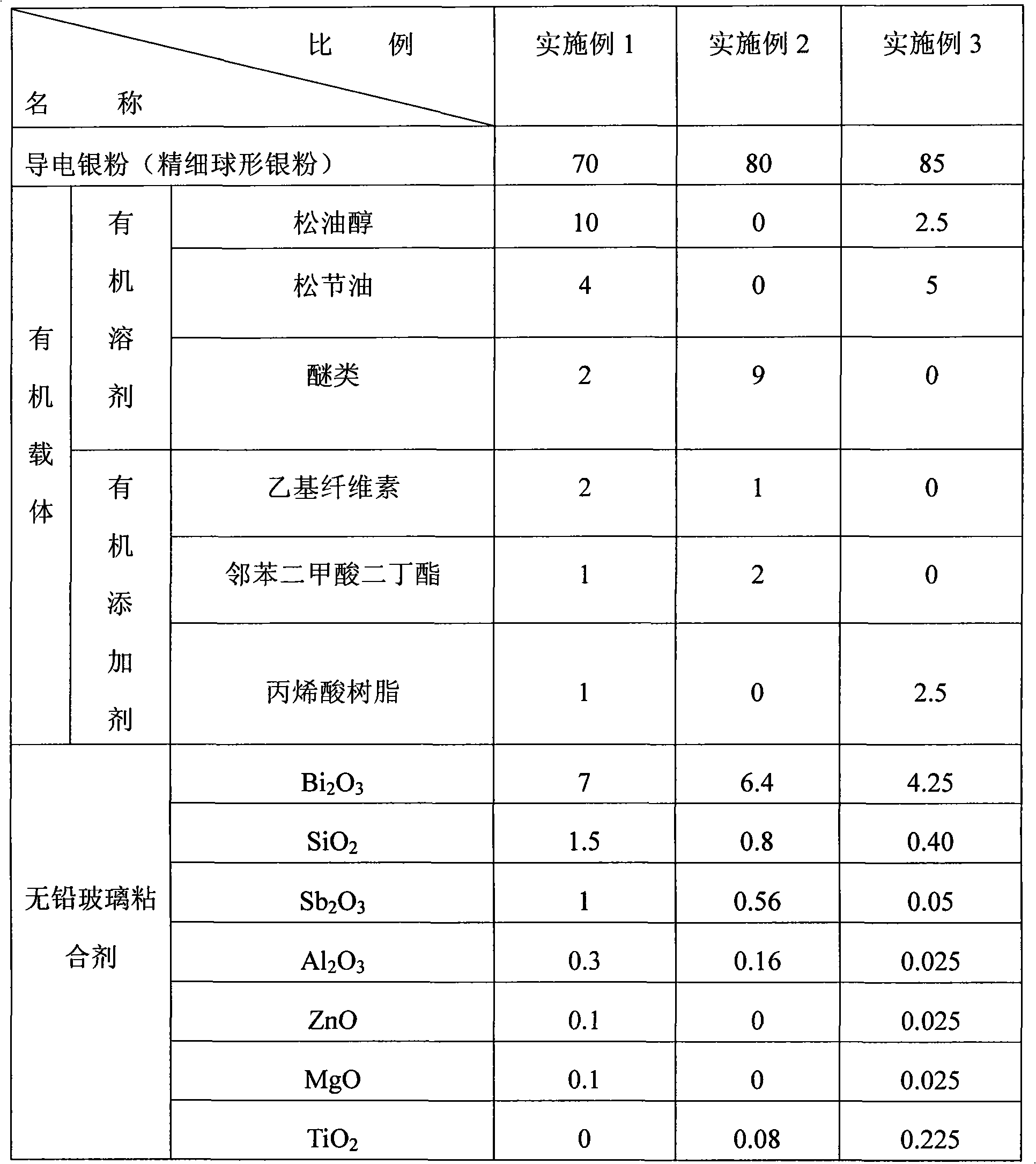

[0018] The embodiment of lead-free solar cell silver paste of the present invention sees the following table:

[0019]

[0020] The technical parameters of the present invention's gained lead-free solar cell silver paste are as follows:

[0021] Maximum particle size ≤ 15μm; average particle size ≤ 9μm; viscosity 160-300Pa.s; solid content 81-83.5wt%; square resistivity ≤ 5mΩ / □; sintering temperature 850-950°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses lead-free solar cell silver serum and a preparation method thereof, which consists of 70-85 percent of conducting silver powder, 5-10 percent of lead-free glass glue and 5.5-25 percent of organic carrier, wherein, the organic carrier consists of organic solvent and organic additive, the organic solvent is any kind of terpineol, terebinth and ethers or their combination; the organic additive is any kind of ethyl cellulose, dibutyl phthalate and acrylic resin or their combination; the particle size of the conducting silver powder is 0.2-2mum; and the lead-free glass glue belongs to bismuth-silicon- antimony glass system. The solar cell silver serum obtained by the method in the invention is lead-free, which complies with requirements of environmental protection, and a conducting electrode with strong adhesive force and low ohm contact resistance can be formed on the surface of the solar cell. The cell has high photoelectric conversion efficiency and is an ideal substituent of the lead silver serum.

Description

Technical field: [0001] The invention relates to a raw material for producing conductive electrodes of solar cells, in particular to lead-free solar cell silver paste and a preparation method thereof. Background technique: [0002] A solar cell is a semiconductor device that can convert solar energy into electrical energy. Under the condition of light, a photogenerated current will be generated inside the solar cell, and the electrical energy can be directly output through the electrodes. [0003] In order to extract the photo-generated current generated by the solar cell, positive and negative electrodes must be made on the surface of the solar cell. Commonly used electrode manufacturing processes include magnetron sputtering, vacuum evaporation and screen printing sintering, etc., but the production costs of magnetron sputtering and vacuum evaporation methods are too high and the economy is poor. At present, lead-containing solar cell conductive silver paste is widely use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/0224H01L31/18H01B1/22H01B13/00C09J1/00C08L1/28C08L33/02

CPCY02P70/50

Inventor 荀建华孙铁囤潘盛刘志刚

Owner EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com