Method for simultaneously removing sulfur dioxide and nitrogen oxide in exhaust air

A technology of nitrogen oxides and sulfur dioxide, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of expensive, unstable and widely used, and achieve simple methods, reduce treatment costs, and economical and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

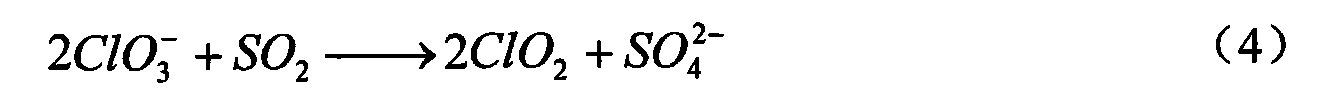

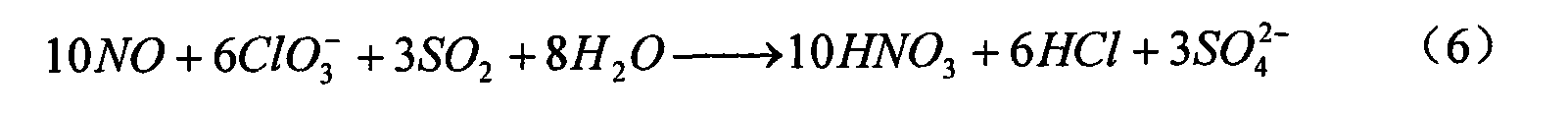

Method used

Image

Examples

Embodiment 1

[0034] Carried out in a bubbling reactor with a diameter of 2 cm and a height of 90 cm, the amount of liquid added to the reactor is 200 ml, and the concentration of sodium chlorate is 0.04 mol l -1 , the pH value is 6;

[0035] The gas flow rate is 200ml / minute, and the temperature is 50°C;

[0036] The gas inlet composition is NO: 480ppm, SO 2 : 1500ppm, O 2 : 5.2%, the rest is nitrogen.

[0037] The gas outlet concentration is analyzed online by an infrared spectrometer, and it is automatically sampled every two minutes. Within 180 minutes, the gas outlet concentration is NO: 30ppm, SO 2 : 200ppm.

Embodiment 2

[0039] It is carried out in a packed tower with a diameter of 2cm and a height of 100cm, the gas-liquid two-phase countercurrent flow, the superficial gas velocity of the tower is 0.1m / s, and the liquid spray density is 5m 3 / m 2 .hr, 500ml absorption liquid is recycled.

[0040] Wherein: sodium chlorate concentration is 0.04mol l -1 , the calcium oxide concentration is 0.03mol l -1 , the pH value is 6,

[0041] The gas flow rate is 200ml / minute, and the temperature is 50°C;

[0042] The gas inlet composition is NO: 480ppm, SO 2 : 1500ppm, O 2 : 5.2%, the rest is nitrogen.

[0043] The absorption liquid is recycled, and the gas outlet concentration is analyzed online by an infrared spectrometer. Automatic sampling is performed every two minutes. Within 300 minutes, the gas outlet concentration is NO: 15ppm, SO 2 : 50ppm.

Embodiment 3

[0045] Reactor and operating conditions are the same as embodiment 2, only 0.03mol l -1 The calcium oxide is changed to 0.03mol l -1 Magnesium oxide, within 300min, the gas outlet concentration is NO: 15ppm, SO 2 : 30ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com