Ultraviolet screen nano-coating liquid for eyeglass and preparation thereof

A technology of coating liquid and ultraviolet rays, which is applied in the field of lens ultraviolet shielding nano-coating liquid and its preparation, to achieve the effects of large output, good coating effect, and strong ability to scatter ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

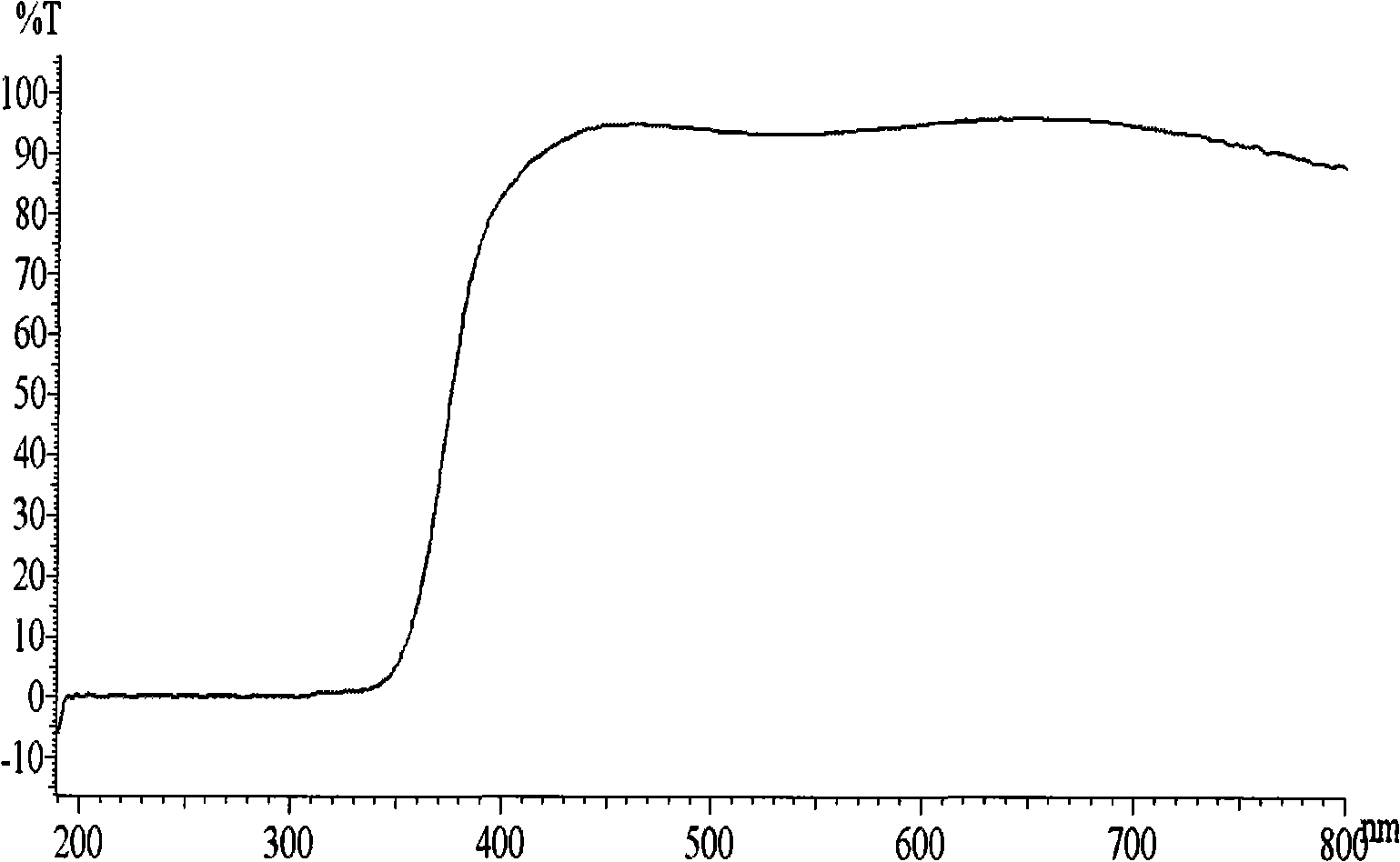

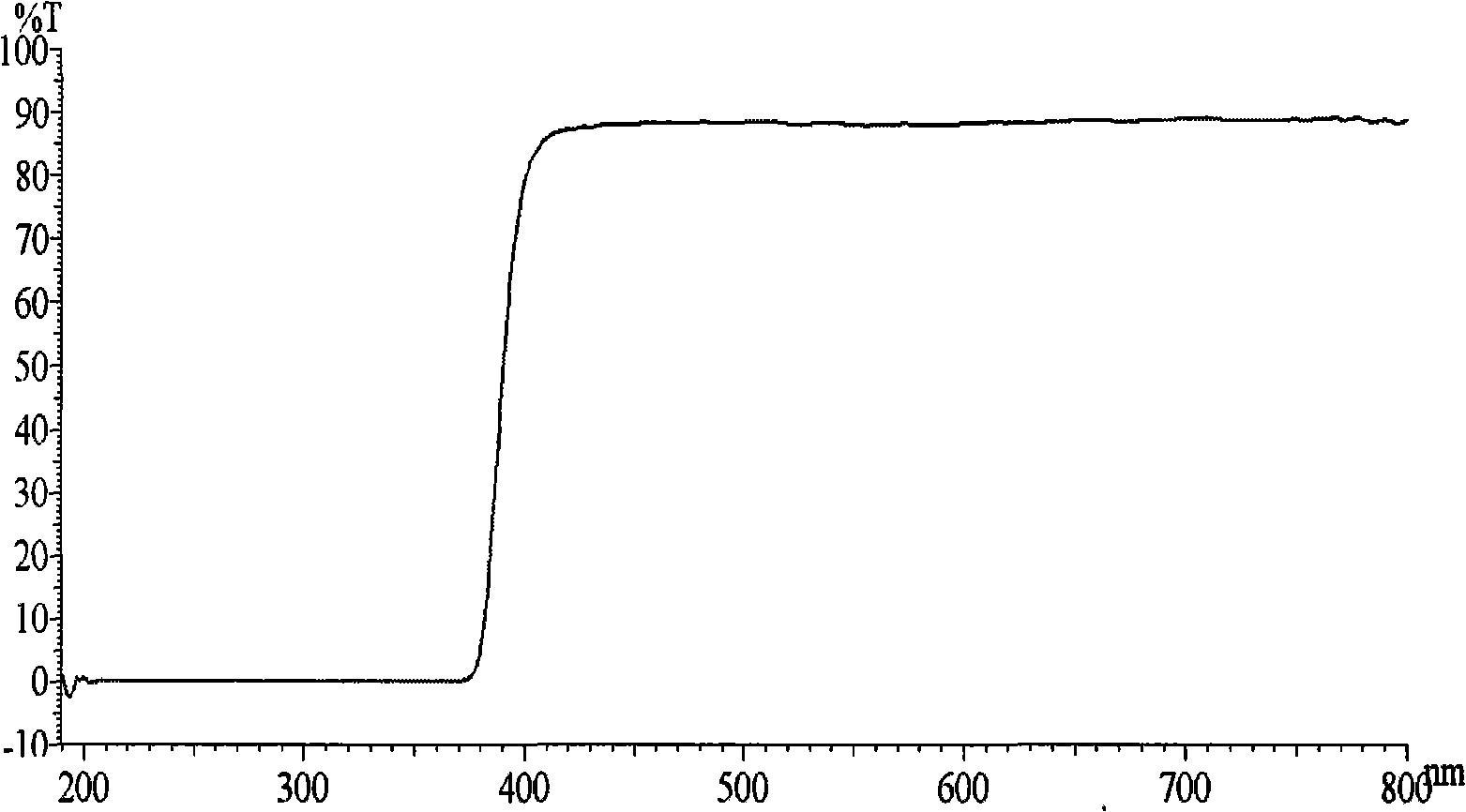

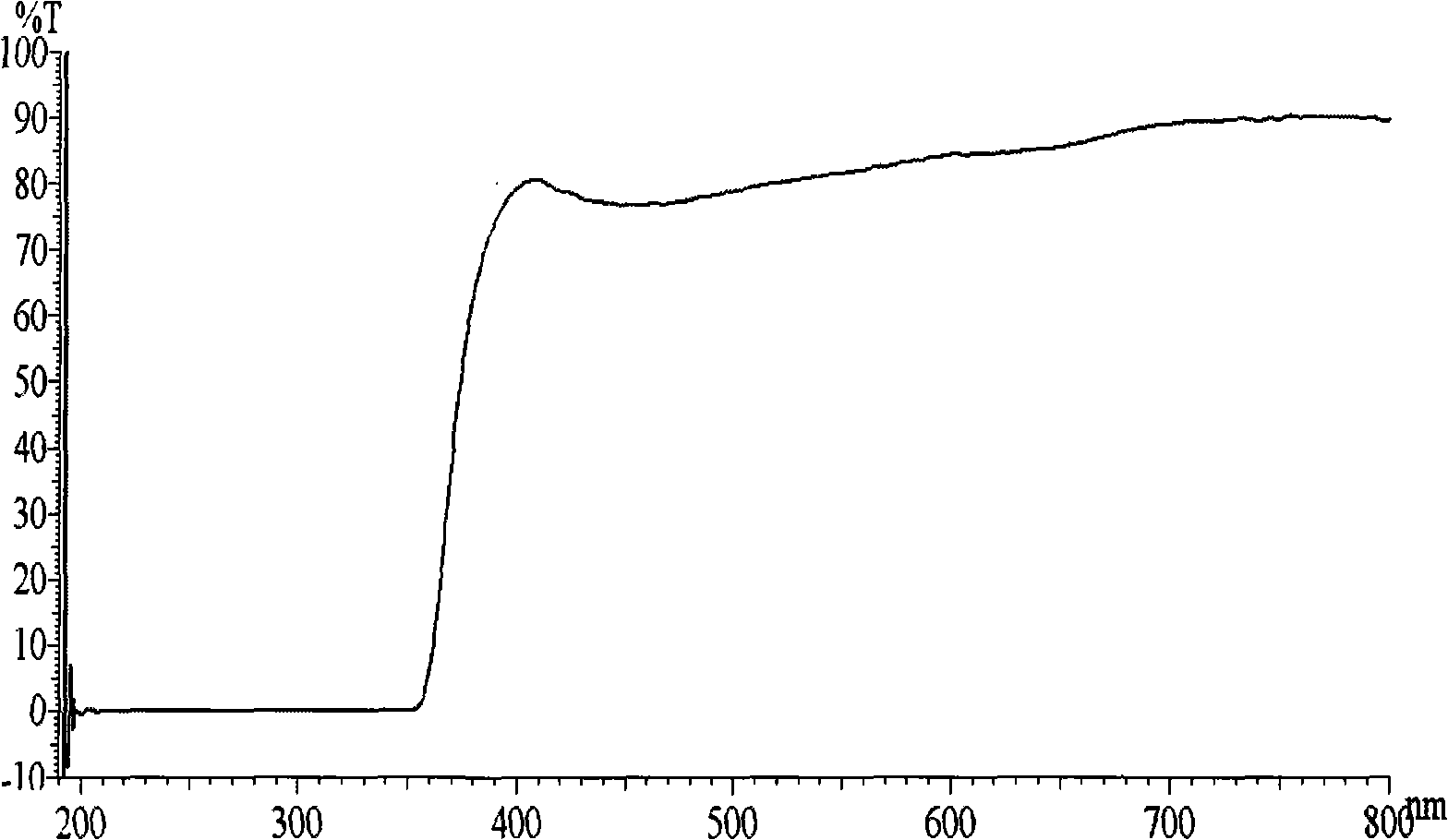

Image

Examples

Embodiment 1

[0021] Weigh 500ml of 0.1mol L -1 Surfactant cetylamine solution, add 500ml 0.5mol L -1 ethanol and 200ml stabilizer (wherein 100ml of 0.2mol L -1 Ammonium acetate solution, 100ml of 0.3mol L -1 glycerol solution), after mixing evenly, the control stirring speed is 3000 rev / min and 5 hours of reaction time, and then add 60 grams of anatase nanomaterial TiO 2-x N x (x=0.1-1, (x is substituted with a specific value) is mainly replaced by nitrogen), after stirring for 60 minutes, then oscillating with an ultrasonic instrument for 30 minutes, and finally filtering with a filter membrane with a pore size of 100nm to obtain a lens coating solution.

Embodiment 2

[0023] Weigh 400ml of 0.5mol L -1 Surfactant dodecylamine solution, add 400ml 0.2mol L -1 propanol and 300ml stabilizer (of which 150ml of 0.4mol L -1 Ammonium citrate solution, 150ml of 0.1mol L -1 liquid polyethylene glycol solution), after mixing uniformly, the control stirring speed is 6000 rev / min and 3 hours of reaction time, after adding 33 grams of anatase nano-material TiO 2-x N x (x=0.1-1, mainly replaced by nitrogen), after stirring for 40 minutes, oscillating with an ultrasonic instrument for 20 minutes, and finally shielding with a shielding film with an aperture of 100nm to obtain a lens coating solution.

Embodiment 3

[0025] Weigh 600ml of 0.3mol L -1 Surfactant tetradecylamine solution, add 400ml 0.7mol L -1的 Ethanol and 500ml stabilizer (250ml of 0.4mol L -1的 Ammonium citrate solution, 250ml of 0.1mol L-1 glycerol solution), after mixing evenly, the control stirring speed is 7000 rpm and 6 hours of reaction time, and then add 120 grams of anatase nano-material TiO 2-x N x (x=0.1-1, mainly replaced by nitrogen), after stirring for 20 minutes, oscillate with an ultrasonic instrument for 40 minutes, and finally shield with a shielding film with an aperture of 100nm to obtain a lens coating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com