Preparation for ferroelectric-ferromagnetic composite nano-fiber

A composite nanofiber and ferroelectric technology, which is applied in fiber treatment, spinning solution preparation, filament/wire forming, etc., can solve the problems of complex process, non-continuous production, easy introduction of impurities, etc., and achieve simple process, The effect of convenient operation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

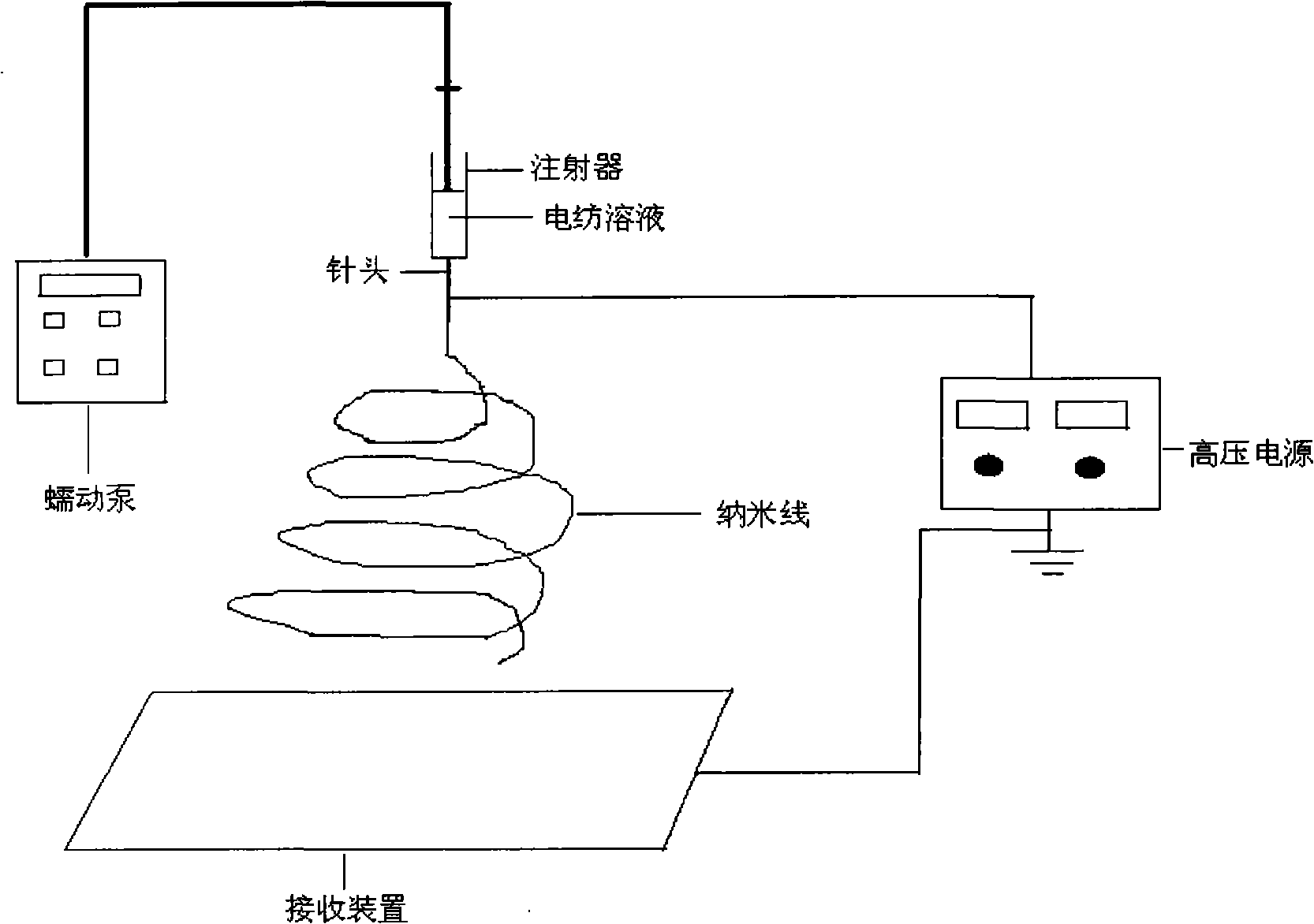

Method used

Image

Examples

Embodiment 1

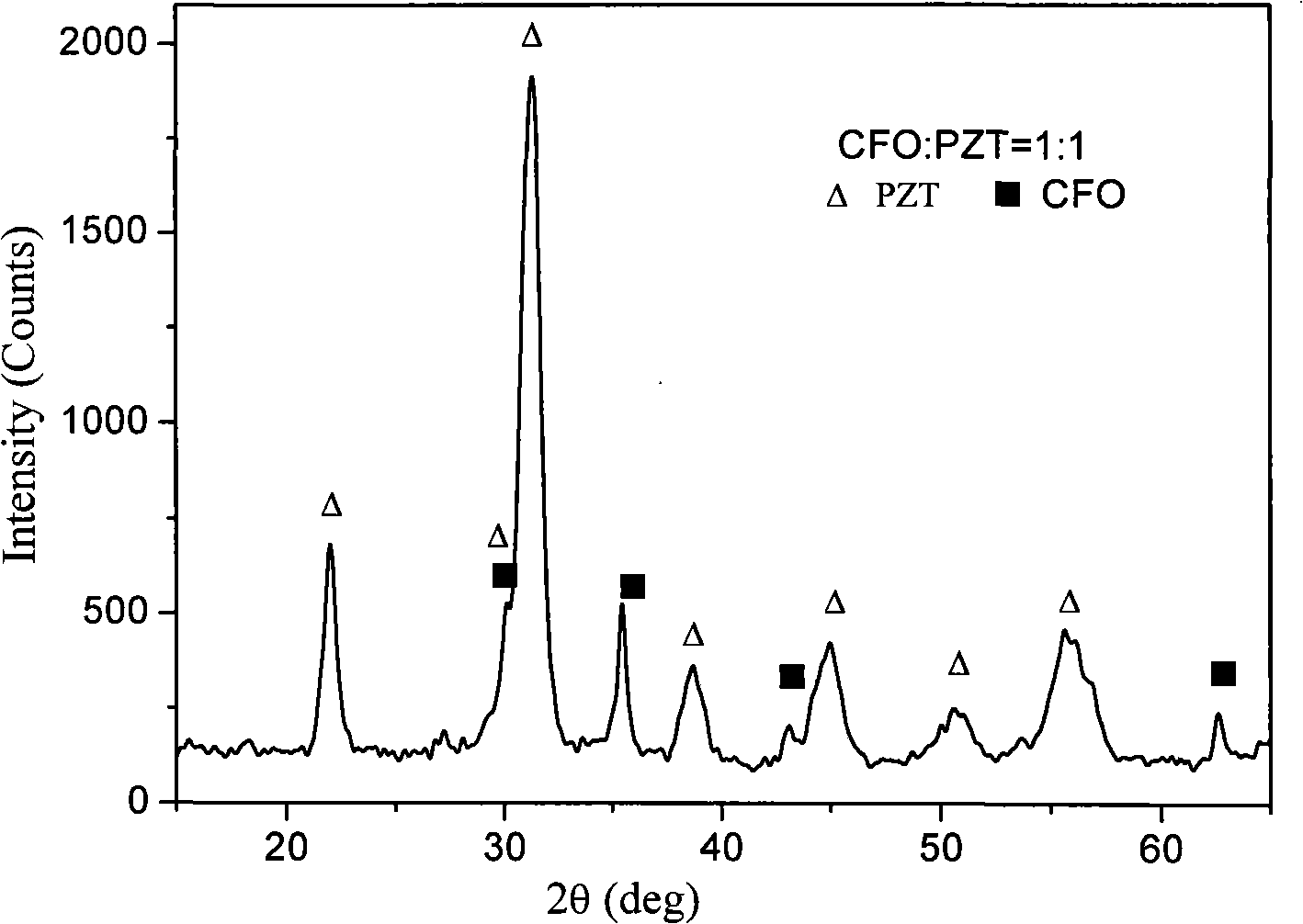

[0026] Use an electronic balance to weigh lead acetate, tetrabutyl titanate and zirconium nitrate, respectively, 0.2276g, 0.0980g and 0.1340g according to the molar ratio of Zr and Ti being 52:48. Lead acetate is dissolved in glacial acetic acid and added to tetratitanate In the ethylene glycol methyl ether solution of butyl ester and zirconium nitrate, the volume ratio of ethylene glycol methyl ether to glacial acetic acid is 5:1, and the 0.3 mol / L PZT precursor solution A is obtained by static filtration. Weigh cobalt nitrate, ferric nitrate and citric acid respectively according to the molar ratio of Co, Fe and citric acid as 1:2:3, 0.1746g, 0.4855g and 0.3780g, dissolve in the mixed solution of ethanol and water, ethanol and water The volume ratio of the ferromagnetic precursor is controlled at about 2:1, and the ferromagnetic precursor solution B of 0.3 mol / L is obtained by static filtration. Add solution A to B, and at the same time add 2ml of a solution dissolving 0.150...

Embodiment 2

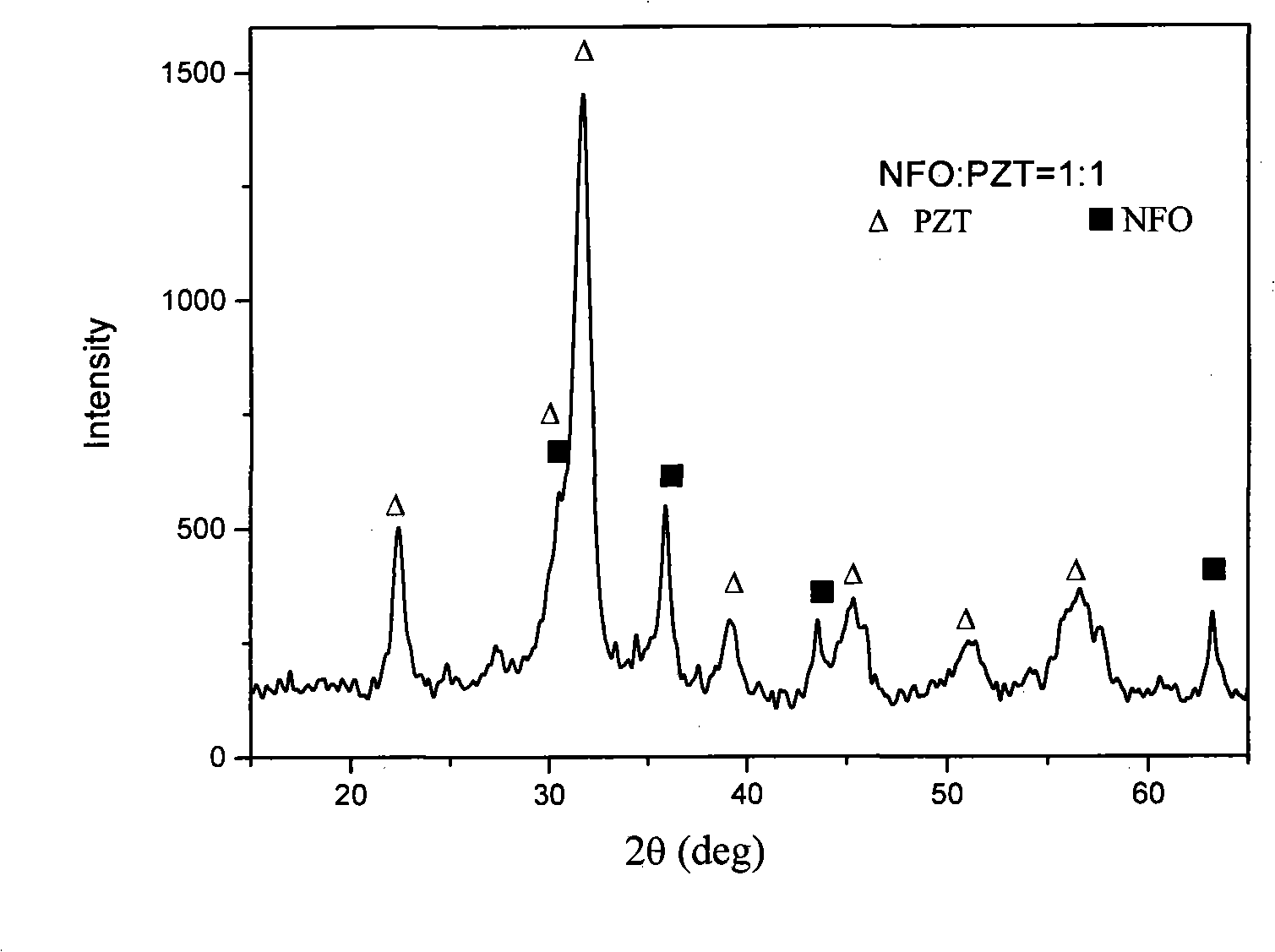

[0028] Use an electronic balance to weigh lead acetate, tetrabutyl titanate and zirconium nitrate, respectively, 0.2276g, 0.0980g and 0.1340g according to the molar ratio of Zr and Ti being 52:48. Lead acetate is dissolved in glacial acetic acid and added to tetratitanate In the ethylene glycol methyl ether solution of butyl ester and zirconium nitrate, the volume ratio of ethylene glycol methyl ether to glacial acetic acid is 5:1, and the 0.3 mol / L PZT precursor solution A is obtained by static filtration. Weigh nickel nitrate, iron nitrate and citric acid respectively according to the molar ratio of Co, Fe and citric acid as 1:2:3, 0.1745g, 0.4855g and 0.3780g, dissolve in the mixed solution of ethanol and water, ethanol and water The volume ratio of the ferromagnetic precursor is controlled at about 2:1, and the ferromagnetic precursor solution B of 0.3 mol / L is obtained by static filtration. Add solution A to B, and at the same time add 2ml of a solution dissolving 0.175g ...

Embodiment 3

[0030] Use an electronic balance to weigh lead acetate, tetrabutyl titanate and zirconium nitrate, respectively, 0.2276g, 0.0980g and 0.1340g according to the molar ratio of Zr and Ti being 52:48. Lead acetate is dissolved in glacial acetic acid and added to tetratitanate In the ethylene glycol methyl ether solution of butyl ester and zirconium nitrate, the volume ratio of ethylene glycol methyl ether to glacial acetic acid is 5:1, and the 0.3 mol / L PZT precursor solution A is obtained by static filtration. Weigh cobalt nitrate, ferric nitrate and citric acid respectively according to the molar ratio of Co, Fe and citric acid as 1:2:3, 0.1310g, 0.3641g and 0.2835g, dissolve in the mixed solution of ethanol and water, ethanol and water The volume ratio of the ferromagnetic precursor is controlled at about 2:1, and the ferromagnetic precursor solution B of 0.3 mol / L is obtained by static filtration. Add solution A to B, and at the same time add 2.5ml of a solution of dissolving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com