Preparation for water retention agent having biochemistry nutrition function

A water-retaining agent and functional technology, applied in chemical instruments and methods, organic fertilizers, agricultural machinery and implements, etc., can solve problems such as unfavorable popularization and application, high product cost, complicated preparation process, etc., to improve soil, stimulate crop growth, The effect of improving the quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

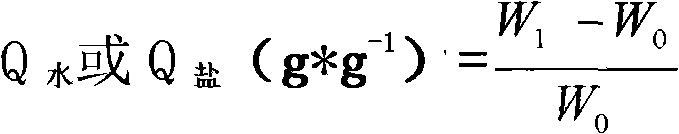

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Put 30 grams of acrylic acid in a reactor, add 160 grams of deionized water and stir to dissolve, use potassium hydroxide to adjust the pH value of the aqueous solution to 5, and dissolve 10 grams of acrylamide with 20 grams of deionized water to prepare an aqueous solution of acrylamide And add it to the neutralized acrylic acid aqueous solution, then add 30 grams of attapulgite, 0.5 grams of ammonium persulfate, 0.05 potassium metabisulfite, 0.2 grams of N, N-methylenebisacrylamide, 0.07 grams of triethanolamine and mix uniform. Nitrogen was blown into the reactor for 30 minutes, and polymerized at 20°C for 4 hours to obtain a gel-like product. The gel product is cut into pieces, dried and pulverized to obtain powdered acrylic acid-acrylamide copolymer. Spray 20 grams of powdered acrylic acid-acrylamide copolymer with 10 grams of 5% humic acid aqueous solution by weight, and dry in a drying oven at 60° C. for 30 minutes to obtain a low-cost water retaining ...

Embodiment 2

[0021] Example 2 Put 100 grams of acrylic acid in a reactor, add 500 grams of deionized water and stir to dissolve, use potassium hydroxide to adjust the pH value of the aqueous solution to 6, and dissolve 90 grams of acrylamide with 140 grams of deionized water to prepare an aqueous solution of acrylamide And add to the neutralized acrylic acid aqueous solution, then add 100 grams of attapulgite, 0.05 grams of potassium persulfate, 0.5 sodium metabisulfite, 0.5 grams of N, N-methylenebisacrylamide, 1 gram of triethanolamine and mix uniformly. Nitrogen was blown into the reactor for 30 minutes, and polymerized at 40°C for 5 hours to obtain a gel-like product. The gel product is cut into pieces, dried and pulverized to obtain powdered acrylic acid-acrylamide copolymer. Spray 50 grams of powdered acrylic acid-acrylamide copolymer with 10 grams of 10% humic acid aqueous solution by weight, and dry in a drying oven at 60°C for 40 minutes to obtain a low-cost water retaining agent ...

Embodiment 3

[0022] Example 3 Put 40 grams of acrylic acid in a reactor, add 408.91 grams of deionized water and stir to dissolve, use 31.09 grams of potassium hydroxide to adjust the pH value of the aqueous solution to 7, and dissolve 20 grams of acrylamide with 100 grams of deionized water to produce propylene Amide aqueous solution was added to the neutralized acrylic acid aqueous solution, and then 50 grams of attapulgite, 0.2 grams of sodium persulfate, 0.1 potassium metabisulfite, 0.05 grams of N, N-methylenebisacrylamide, and 0.2 grams of triethanolamine were added and mix well. Nitrogen was blown into the reactor for 30 minutes, and polymerized at 70° C. for 2 hours to obtain a gel-like product. The gel product is cut into pieces, dried and pulverized to obtain powdered acrylic acid-acrylamide copolymer. Spray 5 grams of powdered acrylic acid-acrylamide copolymer with 10 grams of humic acid aqueous solution with a weight content of 13%, and dry it in a drying oven at 60° C. for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com