Preparation for high-performance solid dye laser medium

A laser medium, high-performance technology, applied in the optical field, can solve problems such as poor light stability, achieve good thermal stability, improve impact and application prospects, and have long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

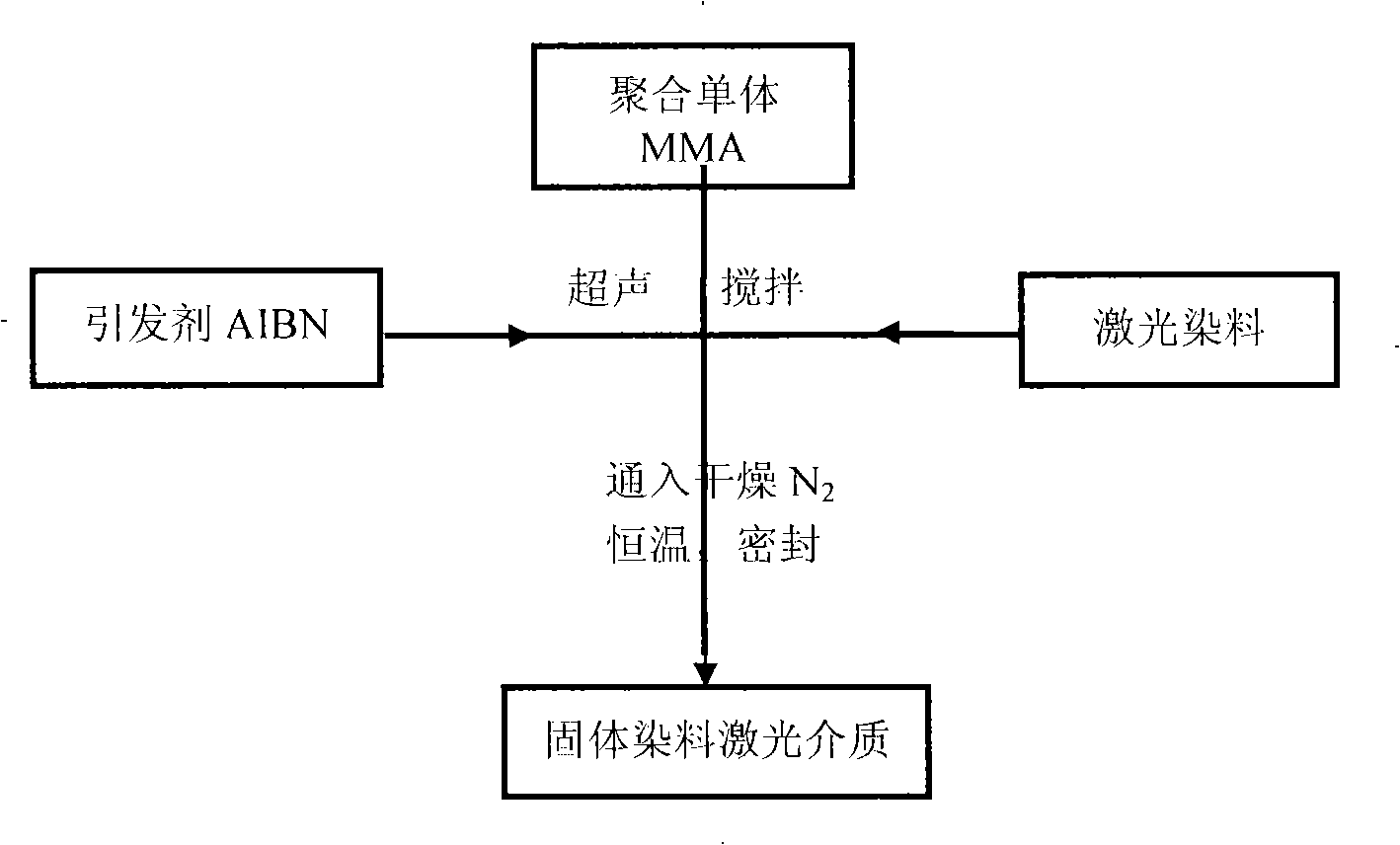

[0038] 1. Preparation of Polymer Matrix Solid Dye Laser Media

[0039] 1.1 Materials required for the preparation of polymer-based solid dye laser media

[0040] Matrix material: methyl methacrylate (MMA)

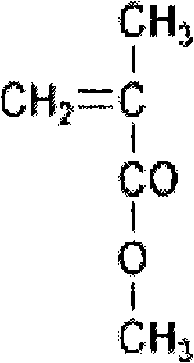

[0041] Polymer monomer MMA can form polymethyl methacrylate (PMMA) through polyaddition reaction. PMMA has the advantages of good optical uniformity and high transmittance in the visible light band and dye laser band. The structural formula of MMA molecule is as follows figure 1 shown.

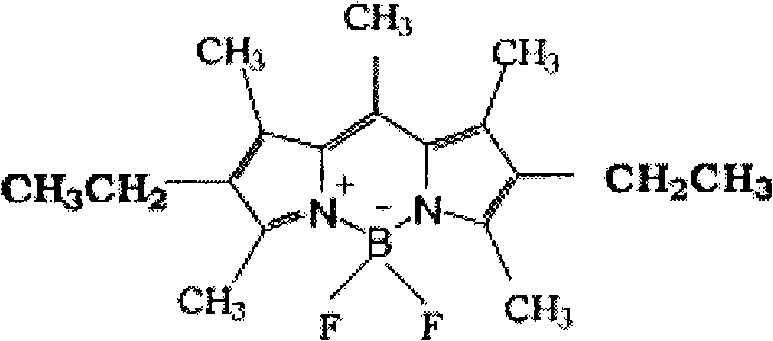

[0042] Laser dyes: PM567, C 440.

[0043] PM567 belongs to pyrromethene (pyrromethene) dyes, which were successfully developed by Boyer and his collaborators in the late 1980s and early 1990s. Its relative molecular weight is 318.22, and its structural formula is as follows: figure 2 shown.

[0044] PM567 has very superior performance:

[0045] (1) It has e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com