Self-healing efficient mortar waterproof agent and preparation thereof

A waterproofing agent and high-efficiency technology, applied in the field of high-efficiency cement waterproofing agent, can solve the problems of increasing the cost of polymer cement waterproofing concrete, high weight of polymer and cement, and high monomer price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] [Example 1]: Weigh 52.075g of commercial polystyrene solid particles, put it into a 1L four-necked bottle, pour 125ml of 1,2-dichloroethane, and raise the temperature to 50-60°C to make the polystyrene swell. 534g 92.5% H 2 SO 4 Transfer to the dropping funnel and add dropwise to the four-necked bottle. At the same time, raise the temperature to 80°C, and adjust the stirring speed to a certain speed. After reacting for 4-5 hours, steam dichloroethane while raising the temperature, react for another 4-5 hours, stop the reaction, and cool down. Then add 190ml of distilled water, heat and stir to 96°C, slowly cool under stirring, filter, wash thoroughly, and dry to obtain a light yellow product.

[0010] Put the sulfonated product in a 2L beaker, add 1200ml distilled water to dissolve, slowly stir and add 31.8g (0.3mol) Na 2 CO 3 . Then add calcium oxide to adjust neutrality, filter to remove calcium sulfate, and the filtrate is sodium polystyrene sulfonate solution f...

Embodiment 2

[0011] [Example 2]: Weigh 52.075g of commercial polystyrene solid particles, add it to a 1L four-necked bottle with a water separator, then add 470ml of chlorobenzene, and adjust the vacuum to make the chlorobenzene reflux at 100±5°C. At this time, slowly add 53g (0.5mol) of 92.5% sulfuric acid dropwise, and continue dehydration until 12.5-13ml of water is produced. Increase the degree of vacuum to evaporate most of the chlorobenzene, and then steam distillation to remove all residual chlorobenzene. Add an appropriate amount of water to dilute, adjust neutral with sodium hydroxide, and prepare for use. By controlling the amount of sulfuric acid added, products with different degrees of sulfonation can be obtained.

Embodiment 3

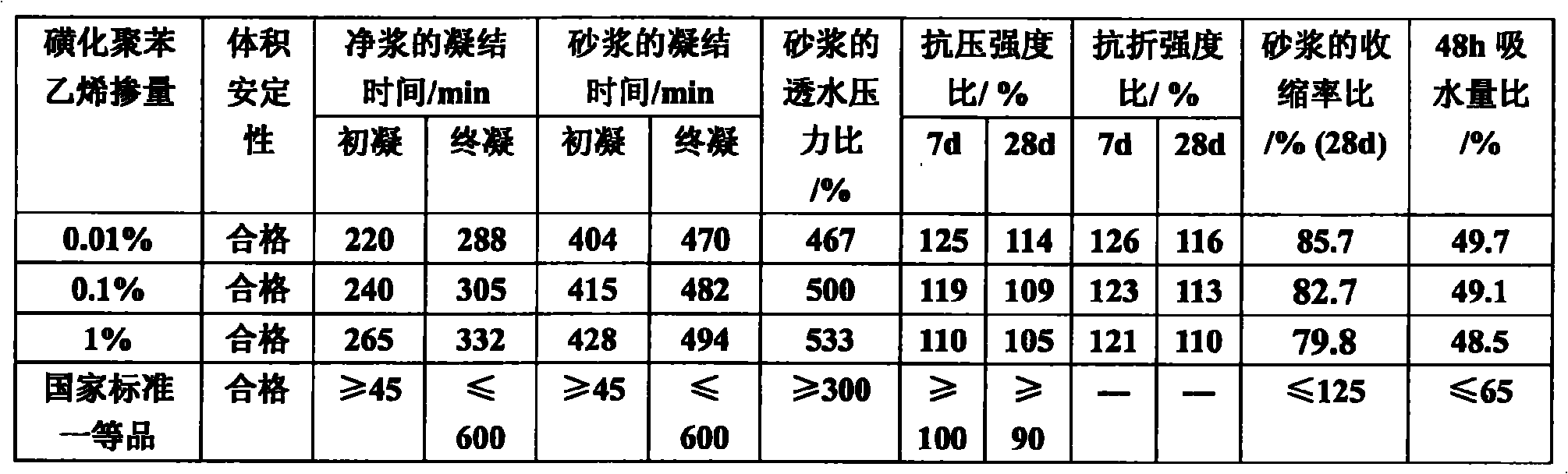

[0012] [Example 3]: use the sulfonated polystyrene obtained in Example 1 as waterproofing agent, use reference cement (Beijing Xingfa Cement Co., Ltd.) and standard sand (Xiamen Aisiou Standard Sand Co., Ltd.), according to national standard JC474 -1999 "Mortar, Concrete Waterproofing Agent"; GB178 "Standard Sand for Cement Strength Test": JC / T603-2004 "Test Method for Drying Shrinkage of Cement Mortar"; GB1346 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method "; GB2419 "Method for Determination of Fluidity of Cement Mortar Sand"; GB8076 "Concrete Admixtures" etc. for testing. The mass ratio of standard cement to standard sand is: 1:3; the water consumption is determined according to the requirements of various tests. Using mechanical stirring, the liquid waterproofing agent is mixed into the mixing water. The concrete vibrating table with a frequency of 50±3HZ and an amplitude of about 0.5mm at no-load is used for compaction, and the vibrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com