Method for continuously producing polyacryl-nitrile pulp-like fibre

A technique for producing polyacrylonitrile, which is applied in wet spinning, textile and papermaking, filament production, etc., can solve problems such as harsh process conditions and difficult control, and achieve simple chemical composition, simple energy consumption, and simplified production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

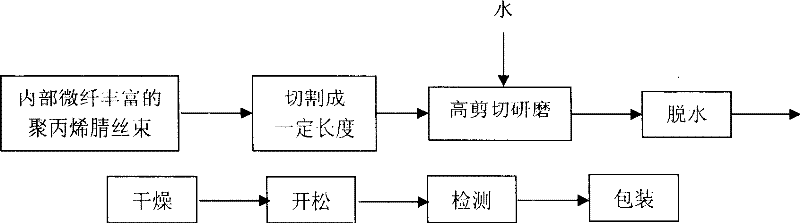

Method used

Image

Examples

example 1

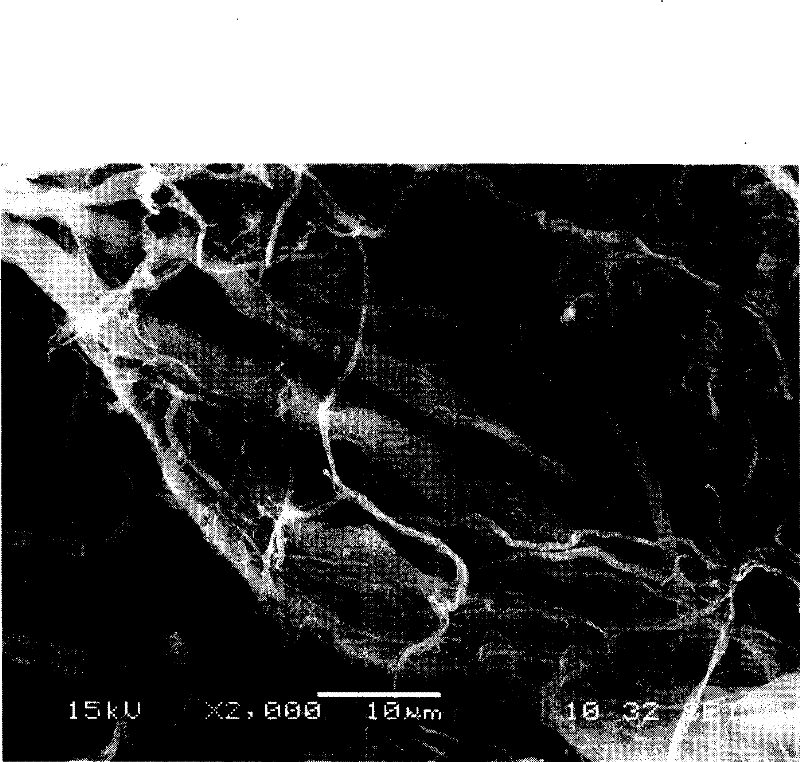

[0024] Each 50wt% of the polyacrylonitrile polymer containing 11.5wt% vinyl acetate and the polyacrylonitrile polymer containing 5.5wt% vinyl acetate are dissolved in 44wt% sodium thiocyanate aqueous solution to form a two-component blend spinning Stock solution, the solution adopts conventional polyacrylonitrile fiber wet spinning process, including spinning, stretching, washing, drying and other processes, to obtain polyacrylonitrile tow with the same appearance as ordinary fiber tow but rich in microfibers inside .

example 2

[0026] The fiber tow that example 1 is obtained is cut into the chopped fiber that length is 4mm in fiber cutting machine, by hollow screw volume feeder, feeds into simultaneously with the deionized water of the speed of 50kg / h and 35t / h flow rate. The disc grinder that pushes the impeller at the feed port is ready to use in 40s -1 Under the action of a high shear rate, the polyacrylonitrile chopped fibers rich in internal microfibers are continuously dispersed and ground in the water phase, and the obtained slurry is dehydrated and dried, and the obtained polyacrylonitrile pulp-like fibers are opened. The distribution is 1.8±0.4mm, and the specific surface area is 12.9m 2 / g.

example 3

[0028] The fiber tow that example 1 is obtained is cut into the chopped fiber that length is 5mm in fiber cutting machine, by hollow screw volume feeder, feeds into simultaneously with the deionized water of the speed of 35kg / h and 40t / h flow rate. The disc grinder that pushes the impeller at the feed port is ready to use in 40s -1 Under the action of a high shear rate, the polyacrylonitrile chopped fibers rich in internal microfibers are continuously dispersed and ground in the water phase, and the obtained slurry is dehydrated and dried, and the obtained polyacrylonitrile pulp-like fibers are opened. The distribution is 2.0±0.4mm, and the specific surface area is 9.6m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com