Fiberglas reinforced plaster tablet and method for making the same

A glass fiber and manufacturing method technology, applied in the field of building materials and their manufacturing, can solve the problems of difficult control of manufacturing quality, difficult glass fiber filaments, cumbersome manufacturing process, etc., and achieve the effects of low production cost, light weight and good acoustic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

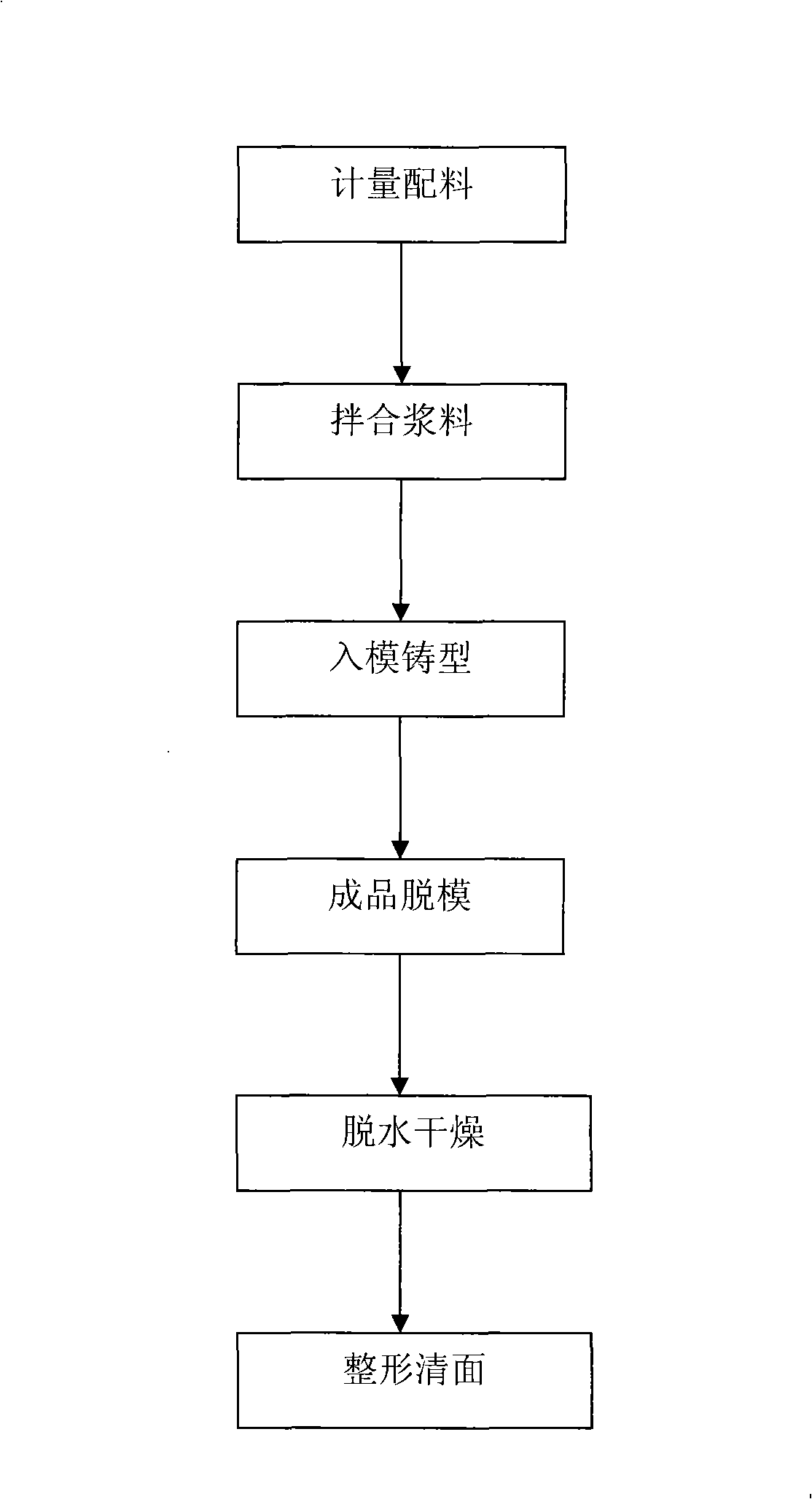

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: glass fiber reinforced gypsum board, its composition and content are respectively: high-strength gypsum powder: 100, the mixing amount of glass fiber short chip mat and glass fiber mesh cloth is 5.0, the mixing amount of water reducer is 0.3 %, the blending amount of the retarder is 0.1%, and the water is fresh water that does not contain oil, hydrochloric acid or organic matter in accordance with the national standard, and its content is 30%.

[0028] The high-strength gypsum powder is an improved α-type calcium sulfate hemihydrate gypsum, which is produced by hydrothermal decomposition. Its crystal characteristics are hexagonal short columns, which is the basis for obtaining ultra-high-strength gypsum. It has a lower standard consistency water demand and High strength, non-flammable properties, neutral (ph value) or weakly alkaline, and its purity is not less than 90% by weight of dihydrate gypsum.

[0029] Table 1 Physical and chemical properties of hig...

Embodiment 2

[0045] Embodiment 2: glass fiber reinforced gypsum board, its composition and content are respectively: high-strength gypsum powder: 100, the mixing amount of glass fiber short chip mat and glass fiber mesh cloth is 5.8, the mixing amount of water reducing agent is 0.4 %, the blending amount of the retarder is 0.2%, and the water is fresh water that does not contain oil, hydrochloric acid or organic matter in accordance with the national standard, and its content is 33%.

[0046] The high-strength gypsum powder still uses improved α-type calcium sulfate hemihydrate gypsum, the water reducer uses HSM high-sulfonated melamine high-efficiency water reducer, and the retarder adopts XB-SG-11 type gypsum retarder Agent, construction steps follow the method of embodiment 1. Various technical indicators of glass fiber reinforced gypsum board are within the standard range.

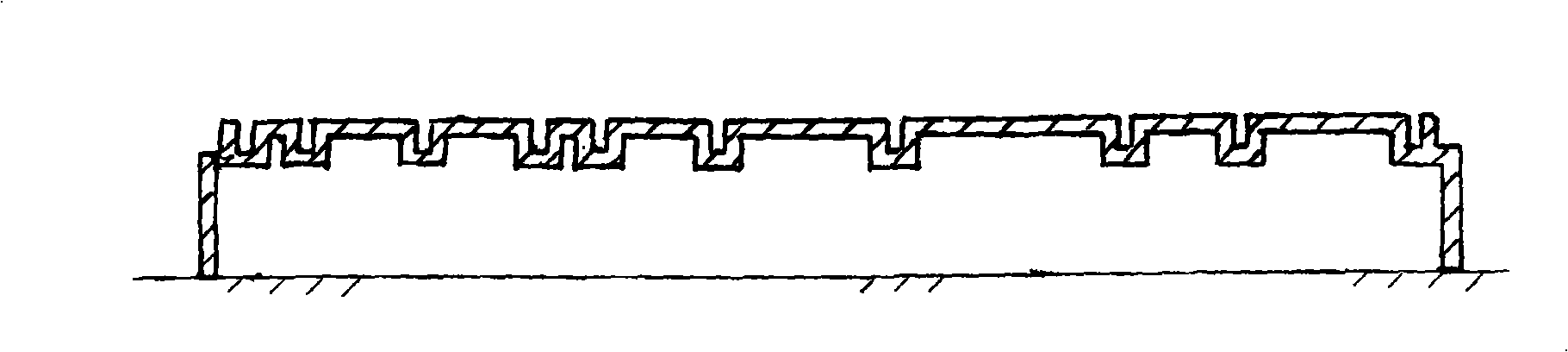

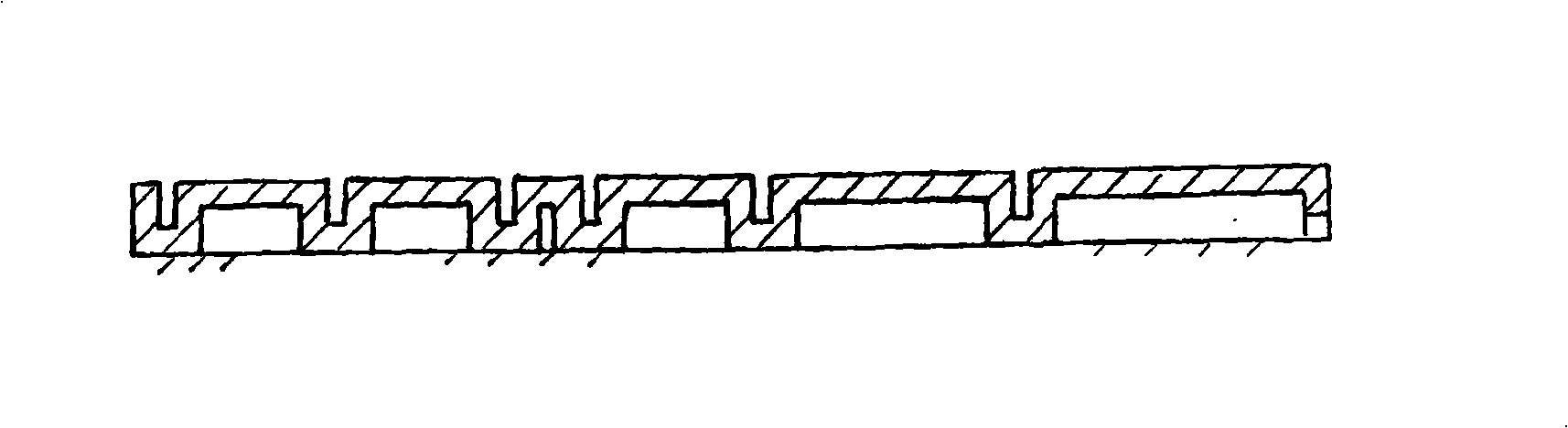

[0047]The glass fiber reinforced gypsum board produced by the present invention can be made by adding different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com