Process for decolorizing sulfolane

A technology of sulfolane and polystyrene, applied in the field of sulfolane decolorization, can solve the problems of loss of exchange capacity, unsuitable removal of organic substances, inability to remove them, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

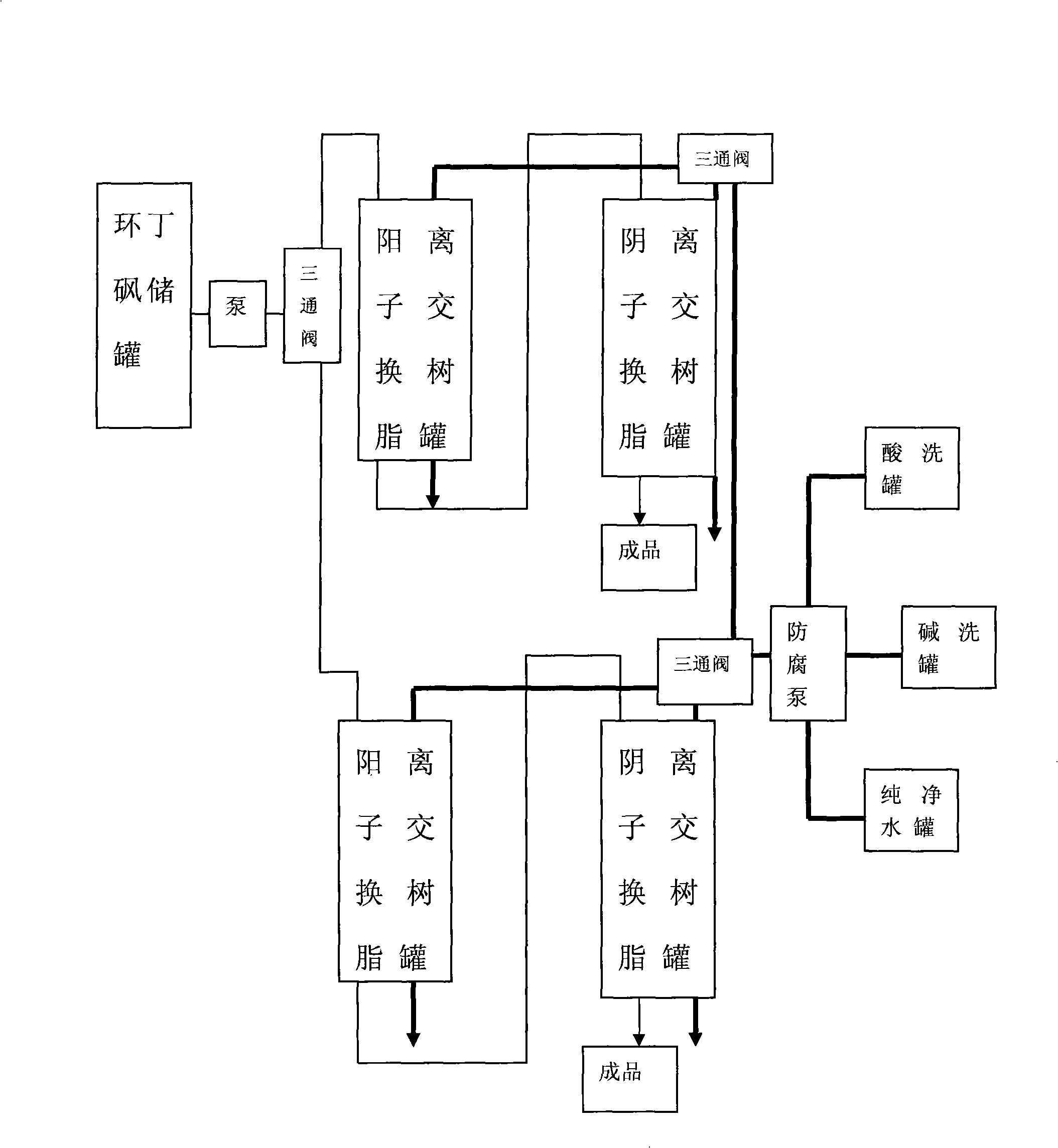

[0014] 1. The structure of the device:

[0015] A D001 type sulfonic acid-based polystyrene large pore size strong acid cation (hereinafter referred to as: large pore size strong acid cation) and a D201 type ammonium polystyrene large pore size strong acid anion (hereinafter referred to as: large pore size strong base anion) The resin tanks are connected in series, and then these two units are connected in parallel. The purpose of connecting two sets in parallel is to switch the inlet of the material to the other set with a three-way valve when one set of resin is regenerated, and the two sets run alternately without affecting continuous production. The performance indexes of D001 sulfonic acid-based polystyrene large pore size strong acid anion resin and a D201 ammonium polystyrene large pore size strong acid anion resin are shown in Tables 5 and 6. They are characterized by very firm structure and low expansion rate after repeated transformation. The exchange speed is fast,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com