Target material for preparing transparent conductive film and method for preparing conductive film and electrode

A technology of transparent conductive film and manufacturing method, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as depletion and depletion, and achieve the effects of fast corrosion rate, low resistivity and small corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] On glass with a thickness of 0.63mm, a 600nm thick Al alloy film was deposited by DC magnetron sputtering AZO ceramic target. During the preparation of the ceramic target, the content of Al-containing elements is controlled at 1at%-10at%, and the content of O2 and the pressure and power of the working gas Ar are controlled. The resistivity of the prepared film was measured by 4-point method at room temperature. Then measure the light transmittance with a spectrophotometer. Test results such as Figure 1-Figure 9 .

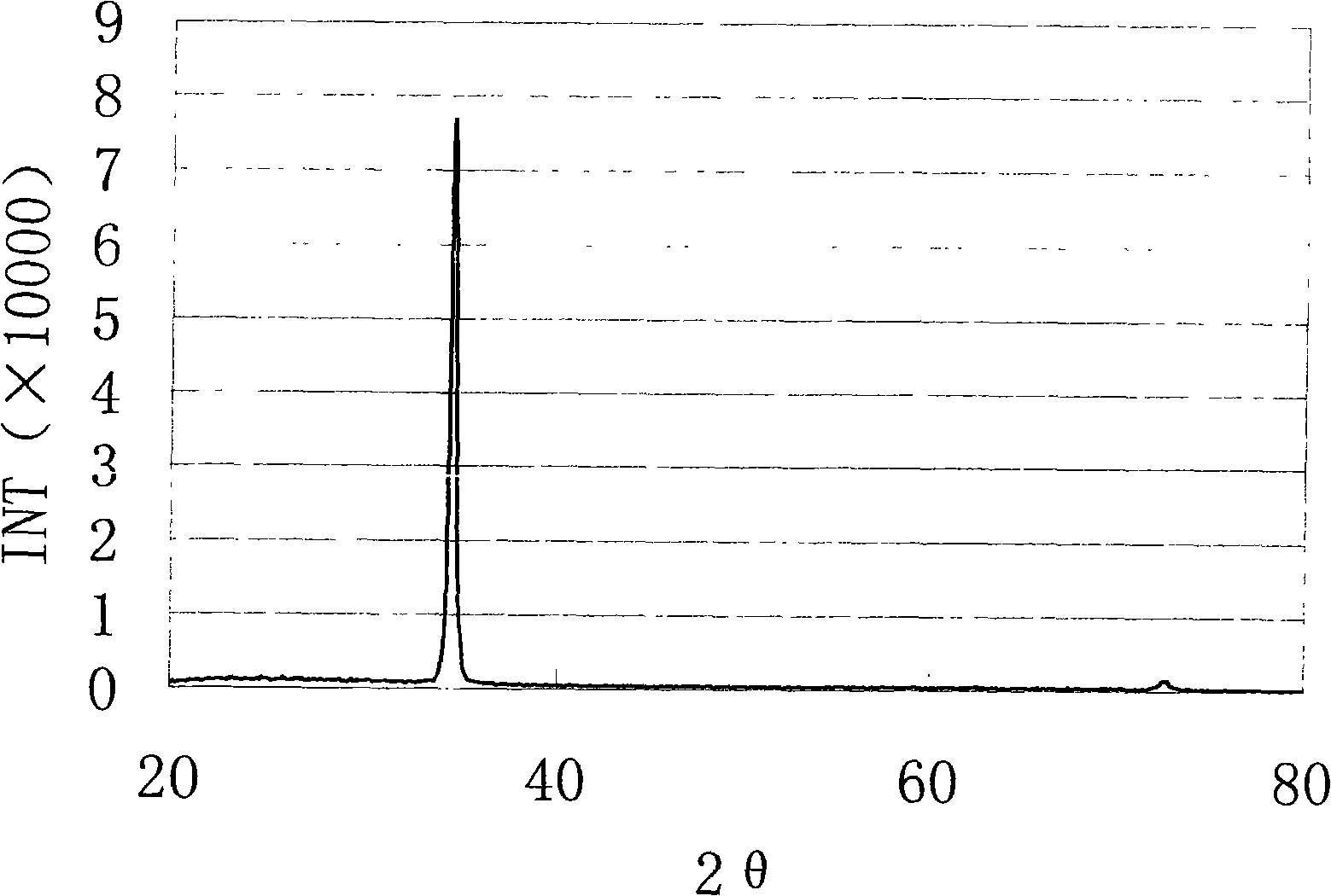

[0034] figure 1 It is the X-ray diffractogram of the AZO film prepared when the substrate temperature is 150°C. from figure 1 It can be seen that its structure is consistent with that of ZnO. Although there is Al doping, the basic structure has not changed.

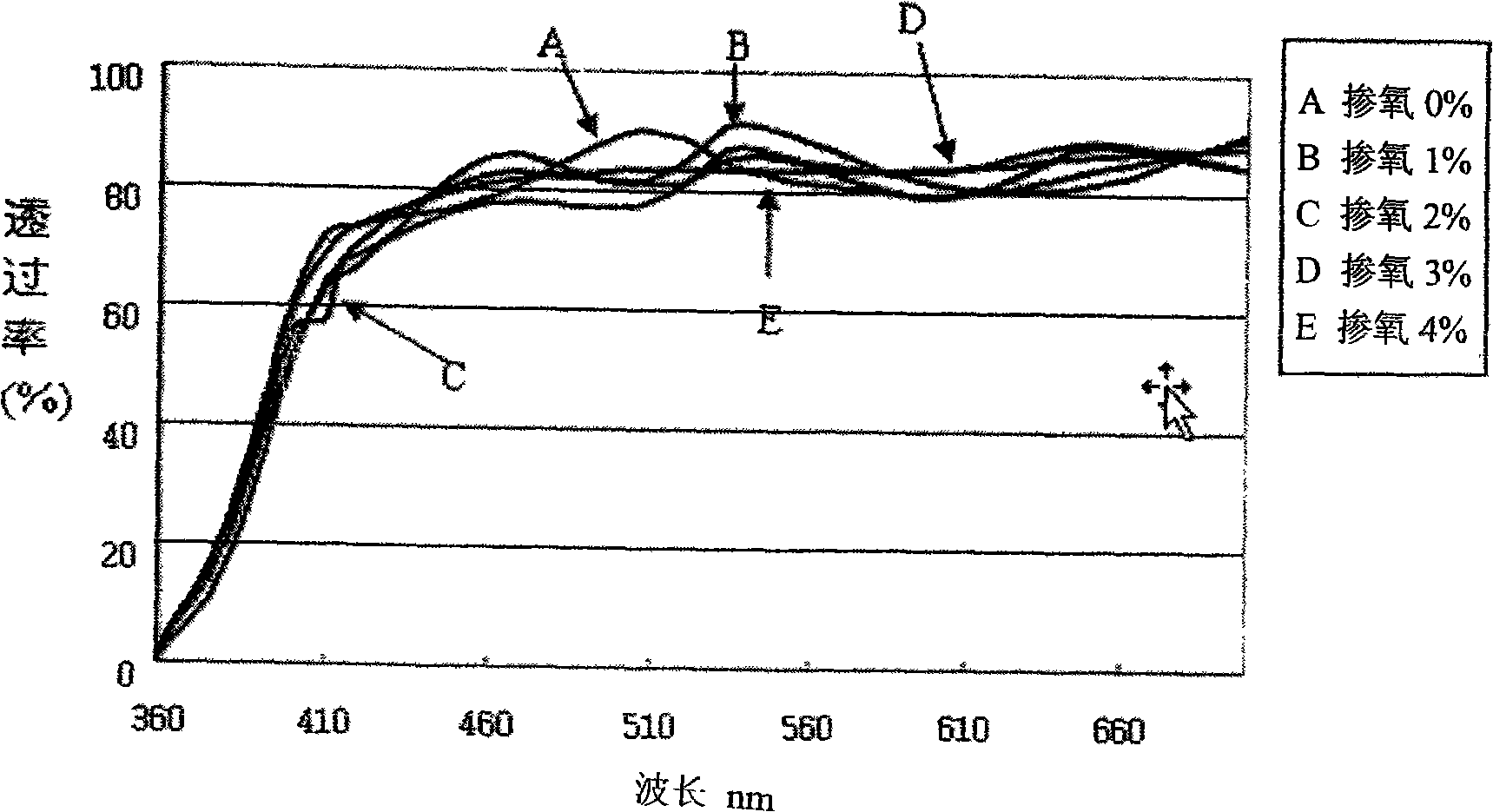

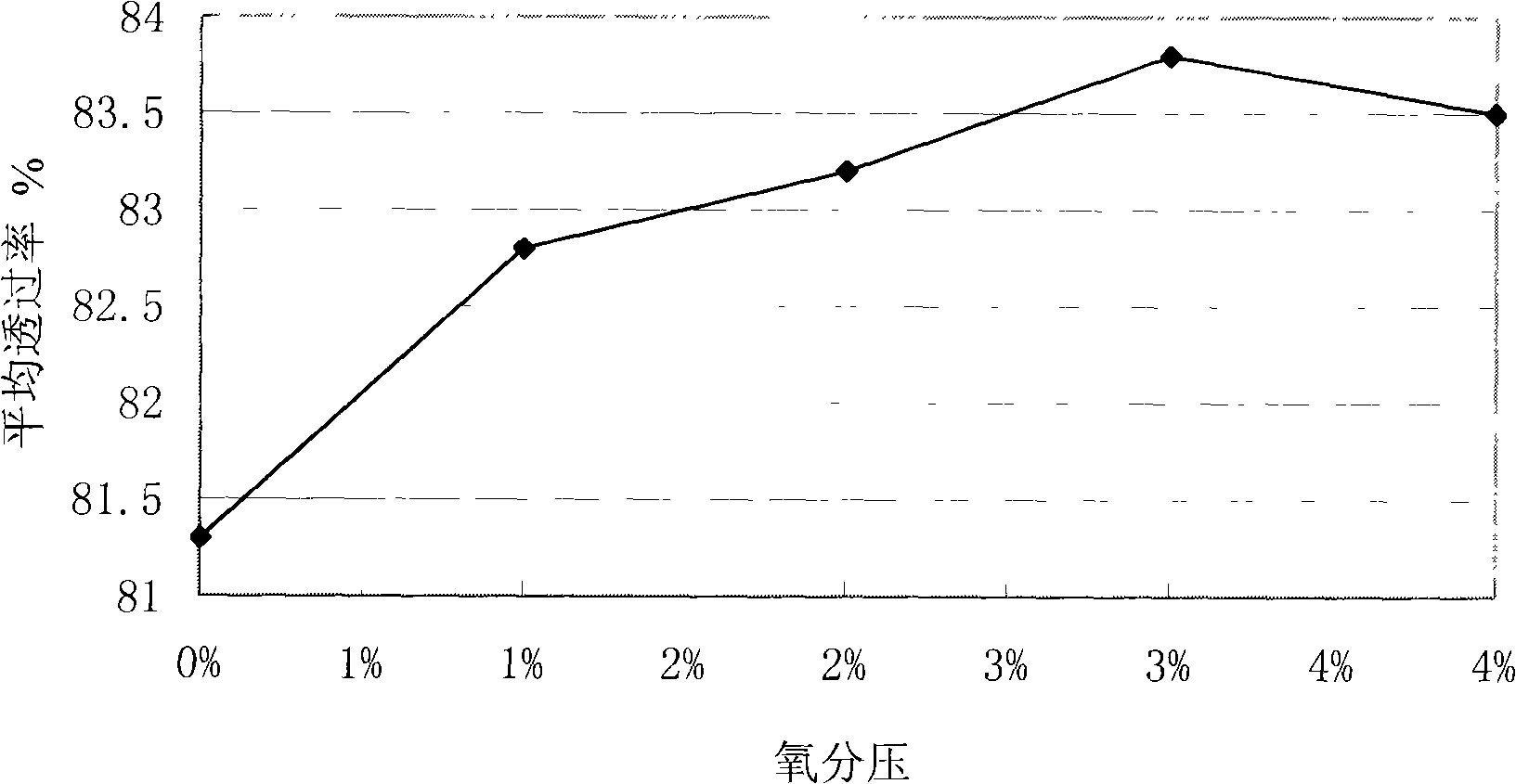

[0035] figure 2 It is the transmittance spectrum of AZO film when doped with different oxygen. from figure 2 It can be seen that for the O2 content in the working gas ranging from 0-4%, the t...

Embodiment 2

[0043] The AZO target is evaporated by electron beam, and the transparent conductive film is deposited on the glass substrate or other media.

Embodiment 3

[0045] If the FPD transparent conductive electrode is prepared, the AZO thin film is first deposited on the glass substrate by magnetron sputtering, and then it is masked by a mask and patterned by photolithography, and then etched to become an electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com