0-50pa single slice silicon based SOI ultra-low micro pressure sensor and its processing method

A micro-pressure sensor, monolithic technology, applied in the field of force-sensitive sensors, can solve problems such as inability to form large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

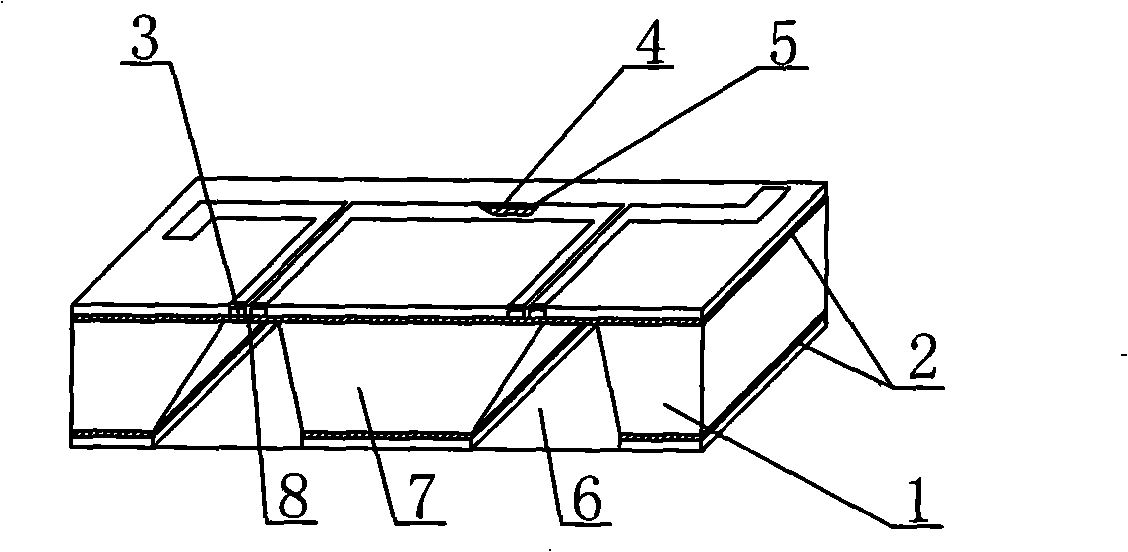

[0022] See figure 1 , figure 2 The chip of the present invention comprises an N-type or P-type silicon substrate 1, covered with an insulating layer 2 on both sides of the silicon substrate, and a single crystal silicon film of about 0.3 micron on the surface of the insulating layer 2 is formed with four SOI force sensitive resistors 3 , the material of the force sensitive resistor 3 is monocrystalline silicon; the single crystal silicon inner lead 4 doped with concentrated boron is connected to the resistor 3; the force sensitive resistor 3 and the single crystal silicon inner lead 4 are attached to the surface of the silicon dioxide insulating layer, and then Covering the silicon nitride insulating layer; covering the surface of the single crystal silicon inner lead 4 with the aluminum lead 5; the SOI single crystal silicon force sensitive resistor 3 is arranged on the center beam and the side beam; the back of the chip has a square opening 6, and two rectangular openings a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com