Nano-carbon generating apparatus

A generation device and nano-carbon technology, applied in nano-carbon, nano-technology, nano-technology and other directions, can solve the problems of burning danger, difficulty in continuously taking out the carbon generated by catalyst input, and difficulty in maintaining a reducing atmosphere, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

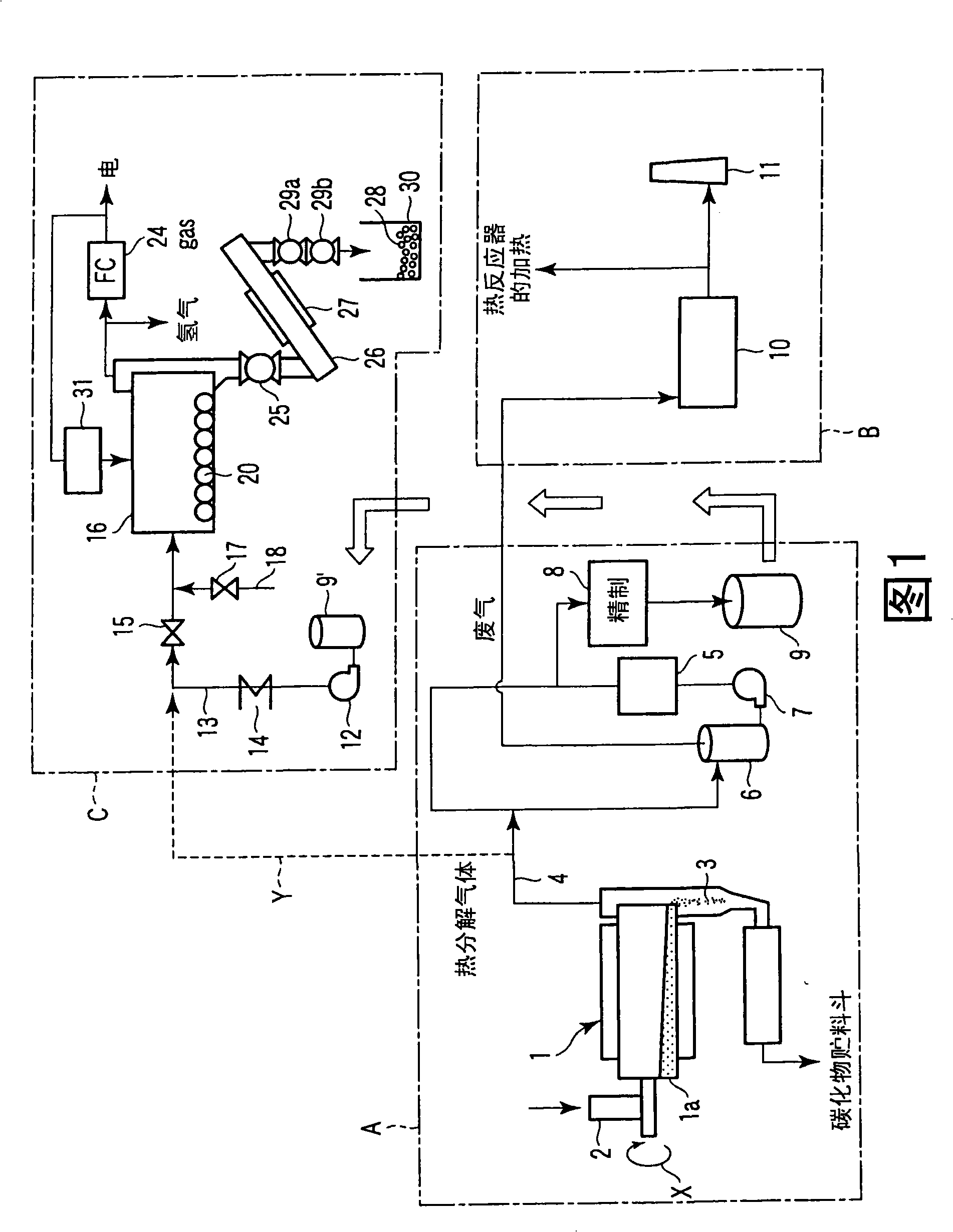

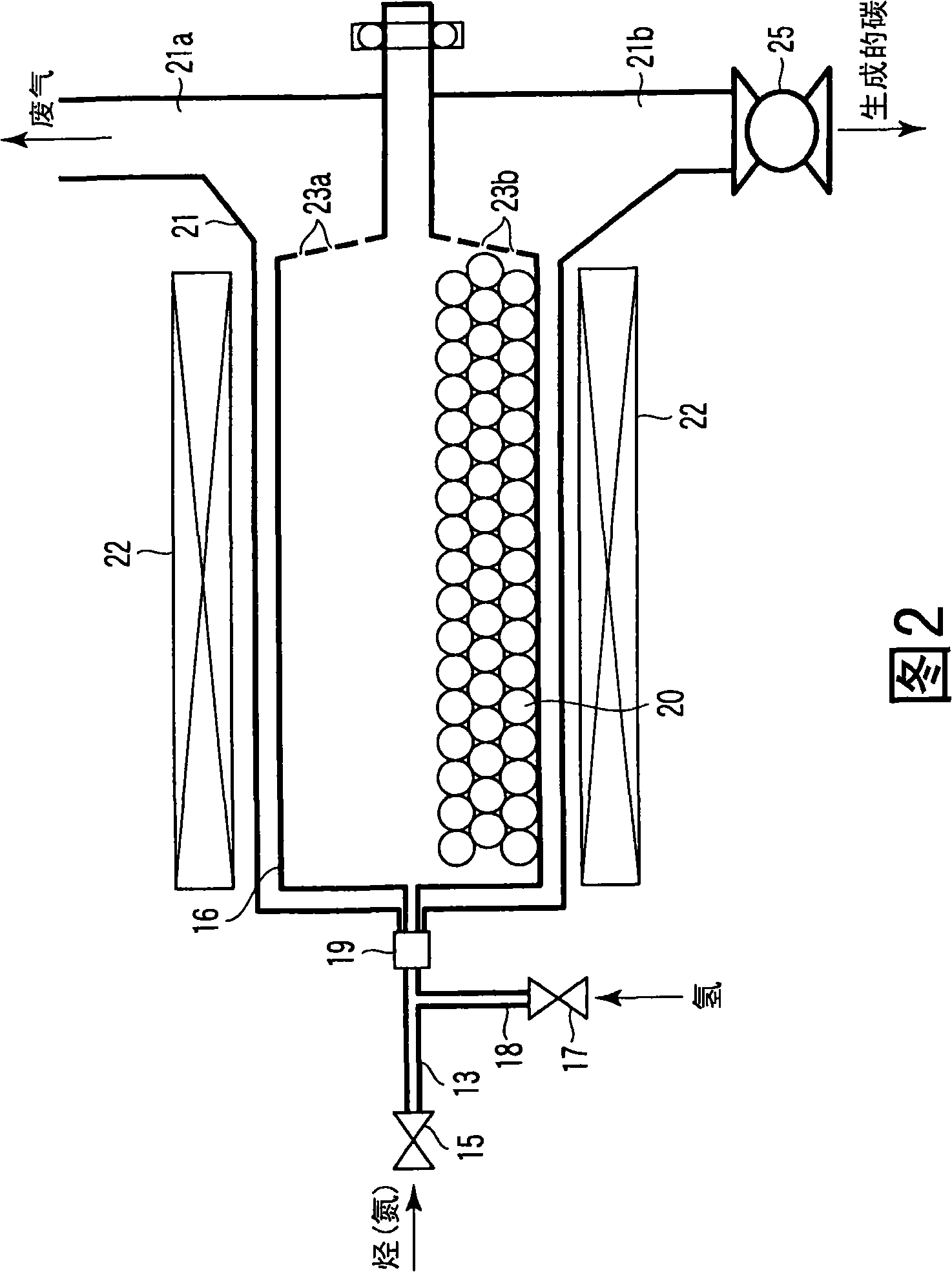

[0025] Refer to Figure 1 and Figure 2. Here, FIG. 1 is a process flow diagram of a nanocarbon production apparatus according to a first embodiment of the present invention. FIG. 2 is an enlarged explanatory diagram of a rotary kiln, which is a configuration of the nanocarbon production apparatus of FIG. 1 , and its surroundings. The process flow chart includes: from raw material input into thermal decomposition device to recovery and refining of liquefied matter to obtain biomass, block A, to block B of waste gas combustion and exhaust obtained in block A, from bio-oil Refined box C that is heated to vaporize to nanocarbons.

[0026] Reference numeral 1 in the figure represents a thermal decomposition mechanism that rapidly thermally decomposes a raw material and a catalyst at a temperature of about 500° C., which are woody biomass resources that are organically processed, and are broken into pieces. This thermal decomposition mechanism 1 has a drum 1a rotating as indicated ...

no. 2 Embodiment approach

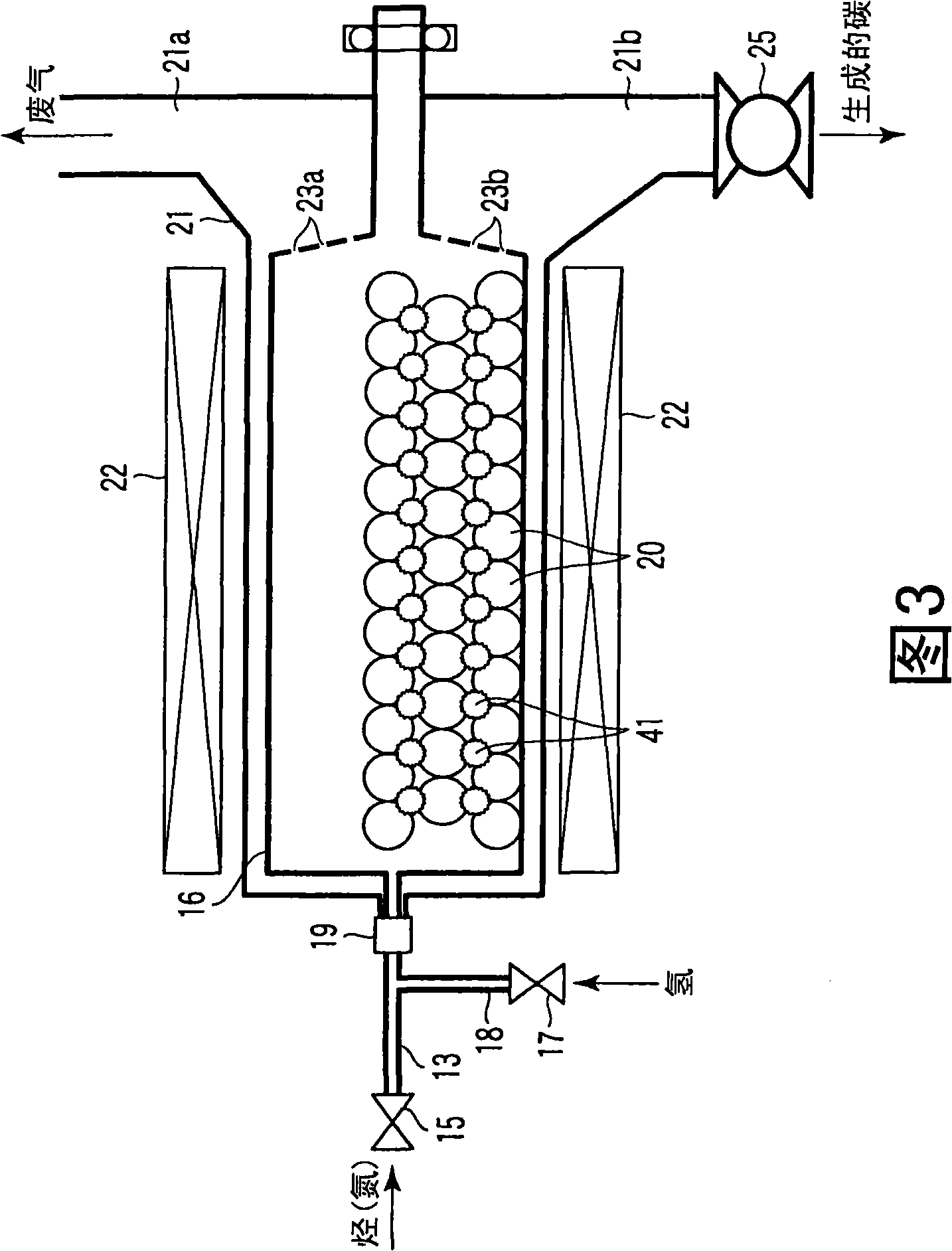

[0044] Refer to Figure 3. Fig. 3 shows only the rotary kiln and its surroundings of the nanocarbon production apparatus of the second embodiment. Here, the same components as those in Fig. 1 and Fig. 2 are given the same symbols and their explanations are omitted.

[0045] The present embodiment is characterized in that, in addition to the SUB metal balls 20 , a large number of superhard balls 41 made of hard ceramics are accommodated in the rotary furnace 16 so as to be mixed with these metal balls 20 .

[0046] According to the second embodiment, the surface of the metal ball 20 is activated by cutting the surface of the metal ball 20 with the superhard ball 41 constantly, and the carbon generated on the metal ball 20 can be peeled off. In addition, since the inner wall surface of the rotary kiln 16 can also be scraped off by the superhard ball 41, it is necessary to harden the inner wall surface of the rotary kiln 16.

[0047] In addition, not only putting the superhard b...

no. 3 Embodiment approach

[0049] This embodiment, not shown in the figure, is characterized in that the above-mentioned metal balls and superhard balls with a rough surface are arranged in the rotary furnace, and the metal balls are hollow and have a volume density equal to that of the superhard balls.

[0050] According to the third embodiment, the volume densities of the metal balls and the superhard balls are equal, so that the metal balls and the superhard balls in the rotary kiln can be uniformly mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com