Sea water silicate drilling fluids

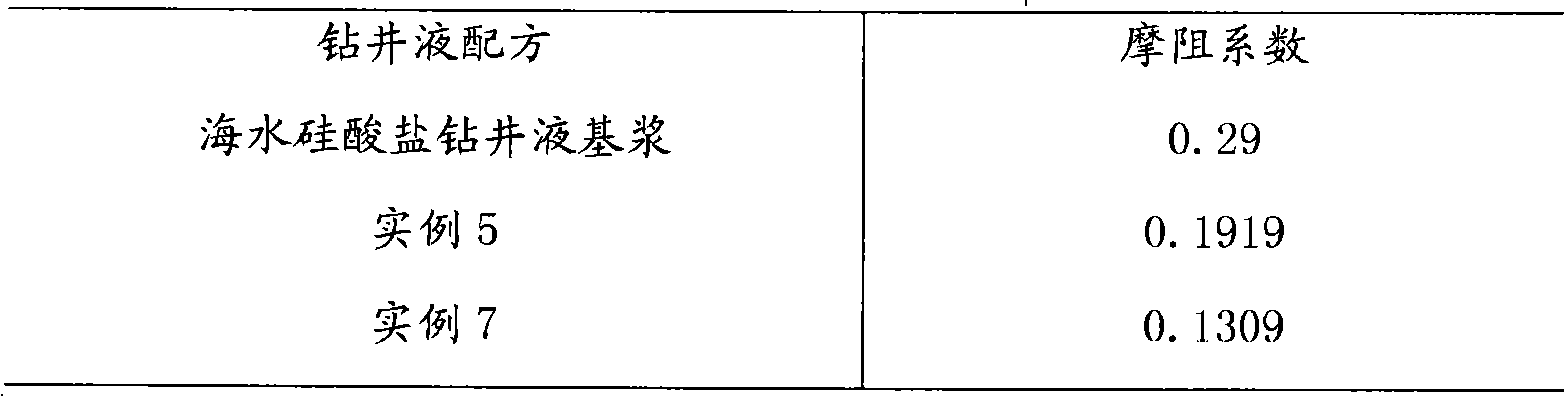

A drilling fluid and silicate technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high dynamic shear force, high static shear force, thick mud cake, and difficulty in tripping out, and achieve anti-drilling Strong pollution ability, small friction coefficient and strong lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation density is 1.54g / cm 3 Seawater silicate drilling fluid base slurry: use a measuring cylinder to measure 100ml of 6% pre-hydrated bentonite slurry and 300ml of seawater into the slurry cup, and add 4.8g of polyanionic cellulose in turn while stirring at a speed of 10,000r / min , 4.0g of modified starch, 28.00g of potassium chloride, 20.00g of sodium silicate, stirred at high speed for 20 minutes, added 273g of barite, stirred at high speed for 30 minutes, this is the seawater-based slurry [2]. Then add 8g of polymeric alcohol lubricant, 8-16g of pyrophosphate, and stir at high speed for 10min;

Embodiment 2

[0040] Prepare seawater-based slurry according to the method of Example 3, add 8g of polyether lubricant, 4-14g of ethylenediaminetetraacetic acid salt, stir at high speed for 10min,

Embodiment 3

[0042] Prepare seawater-based slurry according to the method of Example 3, add 8g of polymeric alcohol lubricant, 12-20g of polyphosphate, and stir at high speed for 10min;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com