Core-shell structured fluorescence granular material with adjustable luminescence and preparation method thereof

A technology of fluorescent particles and luminescent materials, applied in the field of rare earth compound fluorescent materials, can solve the problems of difficult preparation methods, unsuitable for large-scale production, etc., and achieve the effects of important application value, simple preparation process, stable and adjustable light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (Y 2 o 3 :Eu):LnPO 4 The molar ratio is 1:1 core-shell structure fluorescent particle material preparation

[0021] ●Add 0.25molLa 2 o 3 , 0.30molTb (NO 3 ) 3 ·6H 2 O, 0.15molCe(NO 3 ) 3 ·6H 2 O was dissolved in 0.01M dilute nitric acid to prepare a rare earth ion solution.

[0022] ●Respectively take an appropriate amount from the rare earth ion solution prepared in the first step above, and prepare 30mL of rare earth ion mixed solution, the total amount of rare earth ion in the made rare earth ion mixed solution is 2.5mmol, wherein La 3+ 、Ce 3+ , Tb 3+ The amounts of the substances were 1.425mmol, 0.725mmol, 0.35mmol, respectively. And adjust the pH value to 3.0-4.0 with hydrochloric acid, and the pH value is measured by precision pH test paper.

[0023] ●Weigh 2.5mmol sodium tripolyphosphate, dissolve it in 20mL water, adjust the pH value of the solution to about 3.0 with 6M and 1M hydrochloric acid successively, and prepare sodium tripolyphosphate solu...

Embodiment 2-4

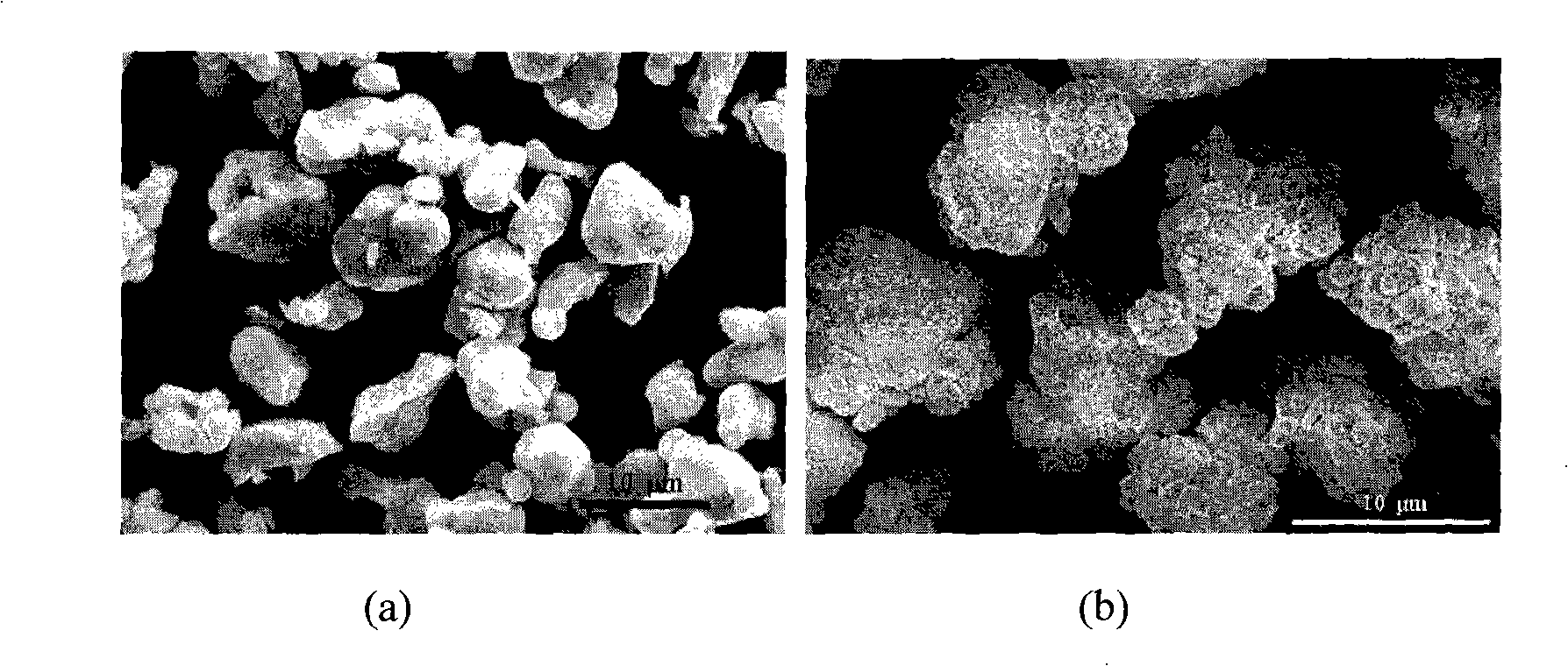

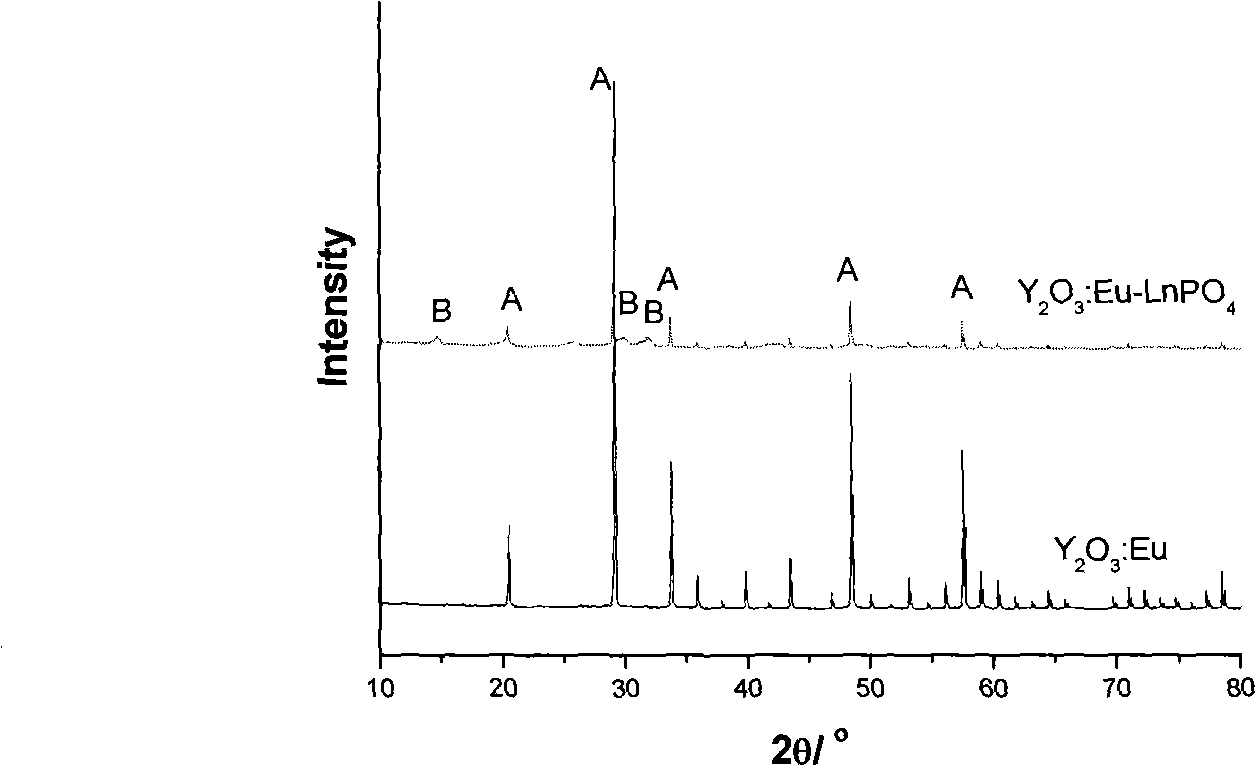

[0030] (Y 2 o 3 :Eu):LnPO 4 The molar ratio of 1: 0.4, 1: 0.8, 1: 1, 1: 2 core-shell structure fluorescent particle material preparation refers to the preparation method of Example 1, the difference is (Y 2 o 3 :Eu):LnPO 4 The molar ratios are 1:0.4, 1:0.8, 1:2, and the size of the obtained core-shell structure fluorescent particle material is 6-16 μm.

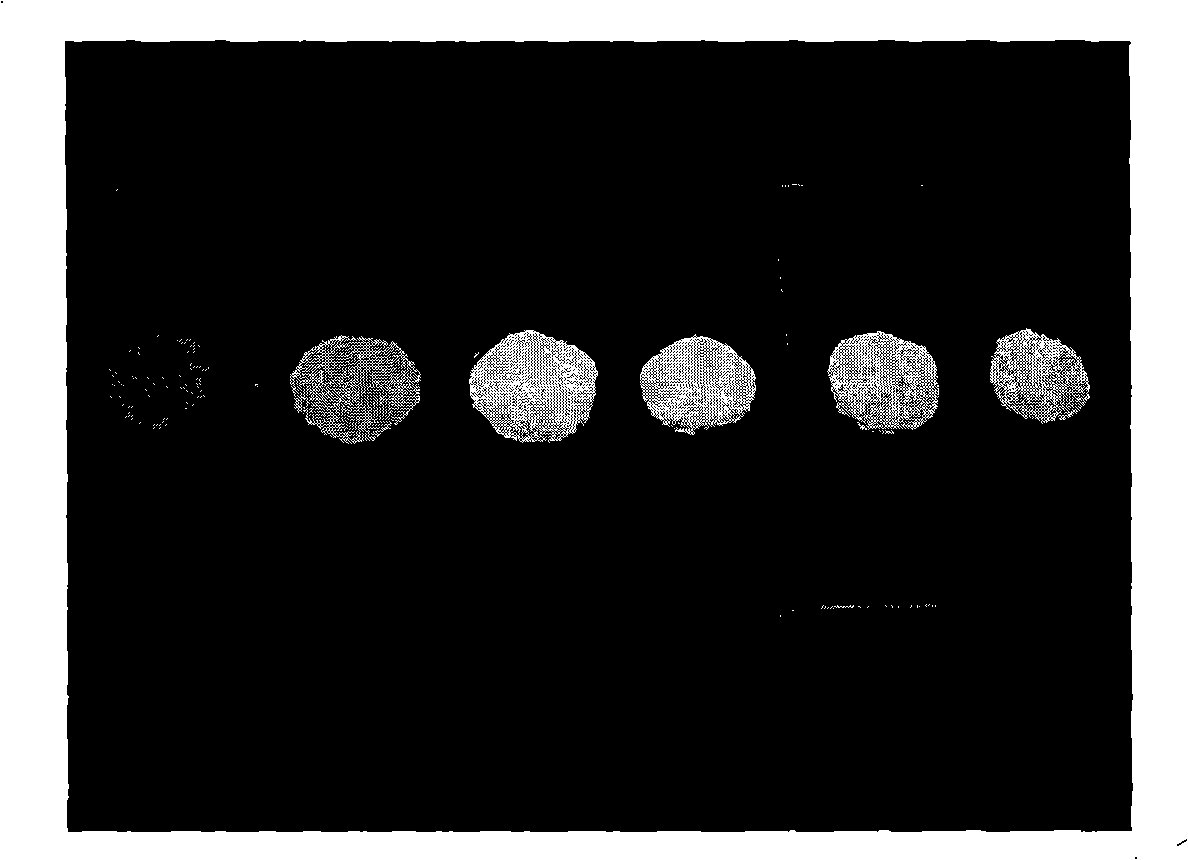

[0031] Excite Y with UV light (254nm) 2 o 3 : Eu-LnPO 4 Fluorescent particles with core-shell structure (see attached image 3 ), the samples from left to right in the figure are: pure Y 2 o 3 : Eu, Y 2 o 3 : Eu-LnPO 4 Core-shell particles (from left to right (Y 2 o 3 :Eu):LnPO 4 The molar ratios are 1:0.4, 1:0.8, 1:1, 1:2), pure LnPO 4 . found that with (Y 2 o 3 :Eu):LnPO 4 As the molar ratio value decreases, the green component of the emitted light of the core-shell structure fluorescent particles gradually increases, and the red component gradually decreases. By adjusting the ratio of the core layer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com