Fabricating method for semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as complexity and reduce the PMOS gate manufacturing process, and achieve the effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

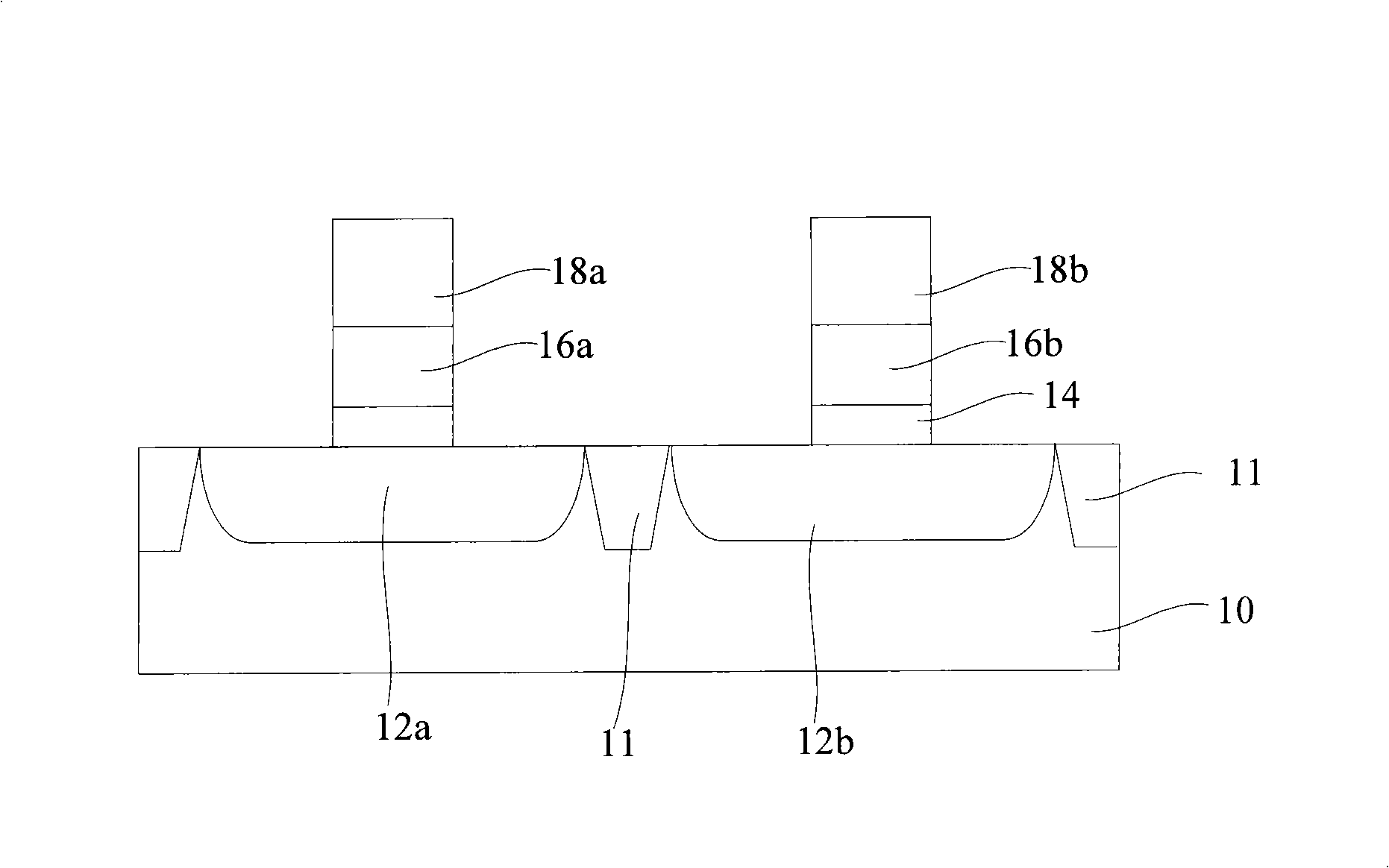

[0070] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0071] Figure 8 It is a flow chart of an embodiment of the manufacturing method of the semiconductor device of the present invention.

[0072] Such as Figure 8 The flow chart shown, step S100, provides a semiconductor substrate having a first region and a second region.

[0073] Such as Figure 9 The schematic cross-sectional view shown provides a semiconductor substrate 30 having a first region 30a and a second region 30b. The material of the semiconductor substrate 30 can be one of monocrystalline silicon, polycrystalline silicon, and amorphous silicon, the material of the semiconductor substrate 30 can also be a silicon-germanium compound, and the semiconductor substrate 30 can also be an insulating layer. Silicon (Silicon On Insulator, SOI) structure or epitaxial layer structure on silicon. N-type impurities or P-type impurities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com