Hydrothermal deposition preparation of load type single metal hydrogenation catalyst

A hydrogenation catalyst and hydrothermal deposition technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems affecting the catalytic activity and active phase structure of catalysts Control, low type I sulfide activity and other issues, to achieve the effect of weakened interaction, strong penetration ability, high reactivity and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

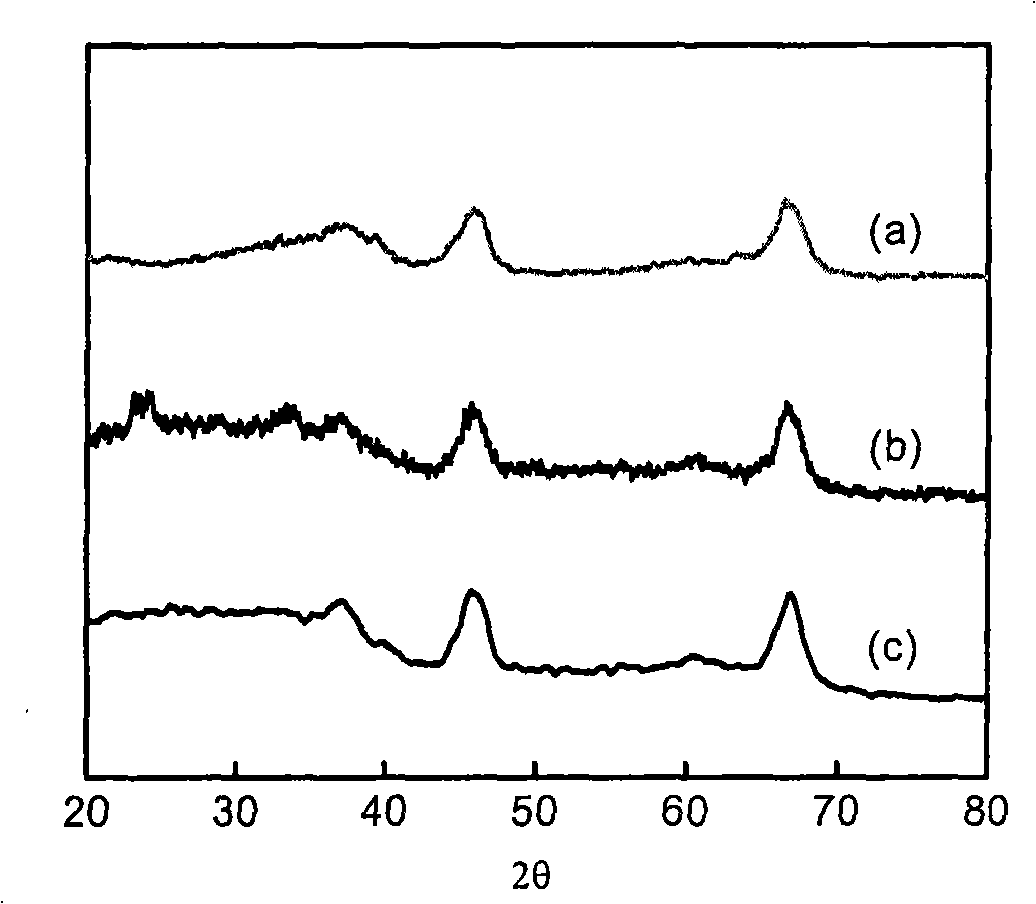

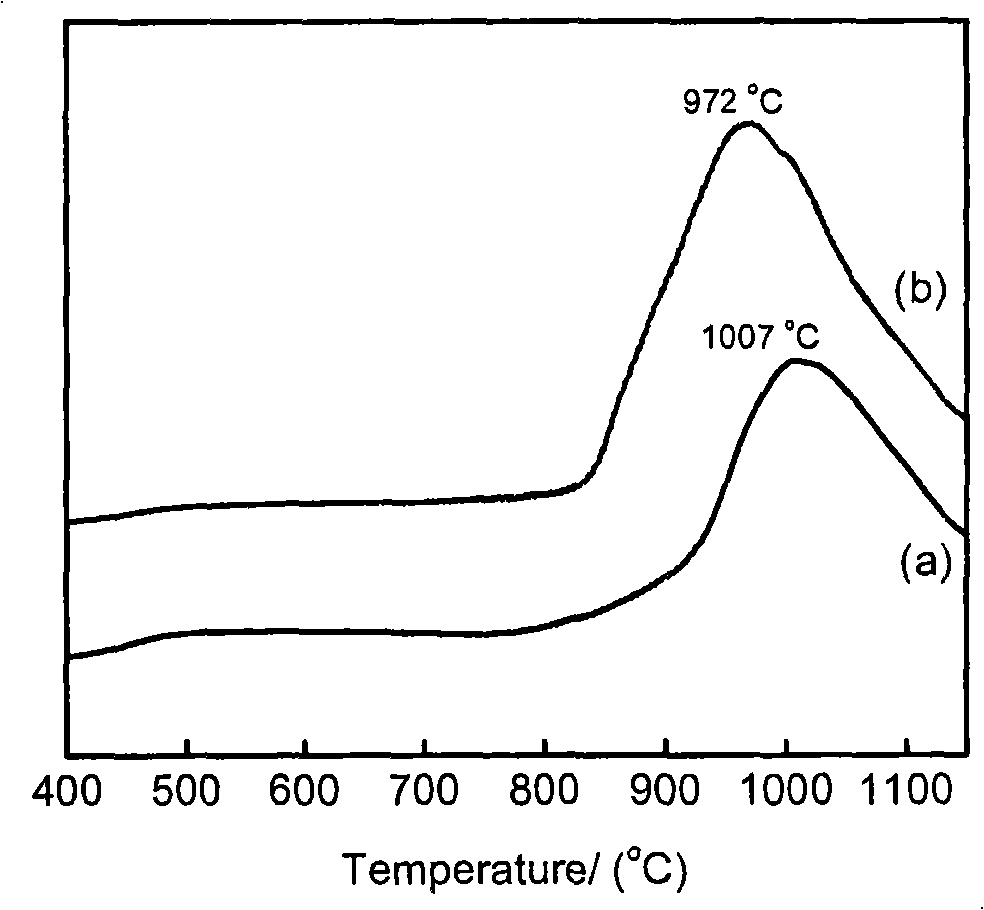

Embodiment 1

[0023] Weigh 20-40 mesh γ-Al 2 o 3 Put 3g of carrier into a 100ml autoclave, add 27.81ml of 0.1mol / l sodium tungstate solution, then add 2.32ml of 2.4mol / l hydrochloric acid, stir evenly, add 3.48ml of 0.8mol / l oxalic acid solution, oxalic acid The molar ratio to sodium tungstate is 1:1. Maintain the temperature up to 150°C, stir and react for 24 hours, cool to room temperature, filter the suspension, wash with water, dry the obtained solid product at 110°C for 2 hours, and roast at 550°C for 4 hours to obtain W / γ-Al 2 o 3 Catalyst S1, the content of tungsten oxide was determined to be 17.7wt% by X-ray fluorescence spectrometry.

Embodiment 2

[0025] Weigh 20-40 mesh γ-Al 2 o 3 Put 3g of carrier into a 100ml autoclave, add 27.81ml of 0.1mol / l sodium tungstate solution, then add 2.32ml of 2.4mol / l hydrochloric acid, stir evenly, add 6.96ml of 0.8mol / l oxalic acid solution, oxalic acid The molar ratio to sodium tungstate is 2:1. Maintain the temperature up to 150°C, stir and react for 24 hours, cool to room temperature, filter the suspension, wash with water, dry the obtained solid product at 110°C for 2 hours, and roast at 550°C for 4 hours to obtain W / γ-Al 2 o 3 For catalyst S2, the content of tungsten oxide was determined to be 17.7wt% by X-ray fluorescence spectrometry.

Embodiment 3

[0027] Weigh 20-40 mesh γ-Al 2 o 3Put 3g of carrier into a 100ml autoclave, add 27.81ml of 0.1mol / l sodium tungstate solution, then add 2.32ml of 2.4mol / l hydrochloric acid, stir well, add 27.81ml of 0.2mol / l oxalic acid solution, oxalic acid The molar ratio to sodium tungstate is 2:1. Maintain the temperature up to 150°C, stir and react for 12 hours, cool to room temperature, filter the suspension, wash with water, dry the obtained solid product at 110°C for 2 hours, and roast at 550°C for 4 hours to obtain W / γ-Al 2 o 3 For catalyst S3, the content of tungsten oxide was determined to be 17.7wt% by X-ray fluorescence spectrometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com