Multi-stage refluxing load control biological process and matched facilities

A backflow load, biological method, applied in water/sewage multi-stage treatment, aerobic and anaerobic process treatment, chemical instruments and methods, etc. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

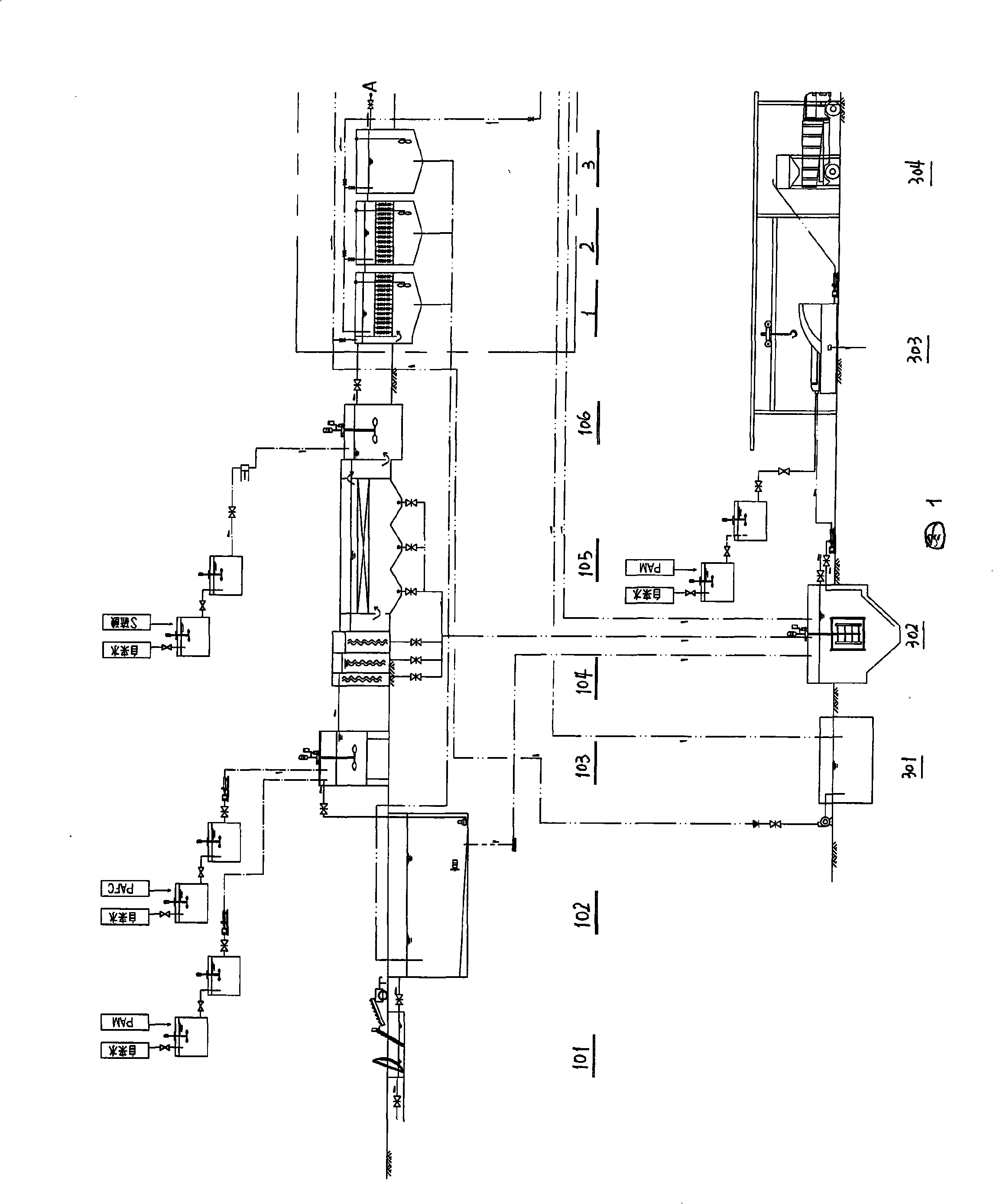

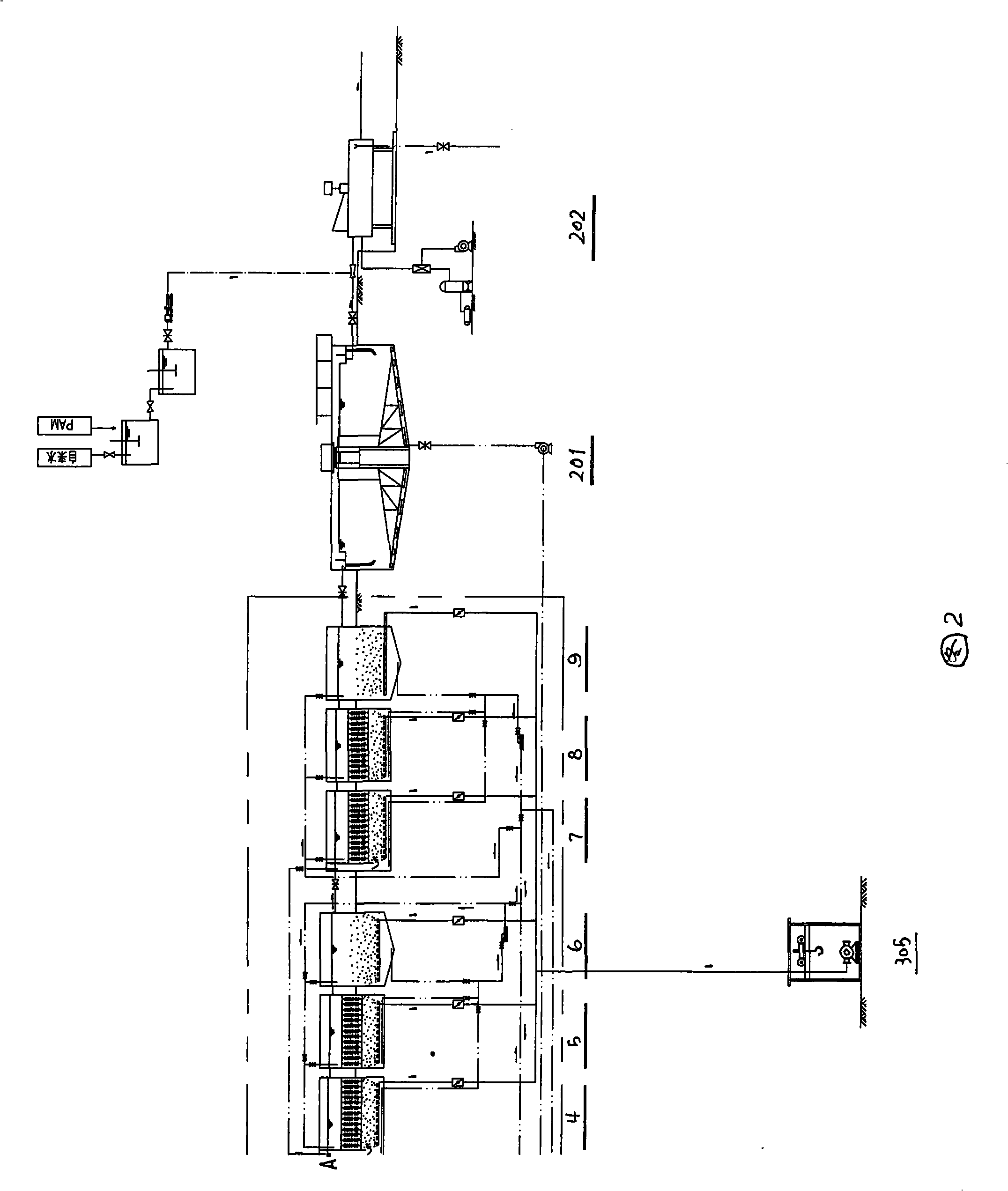

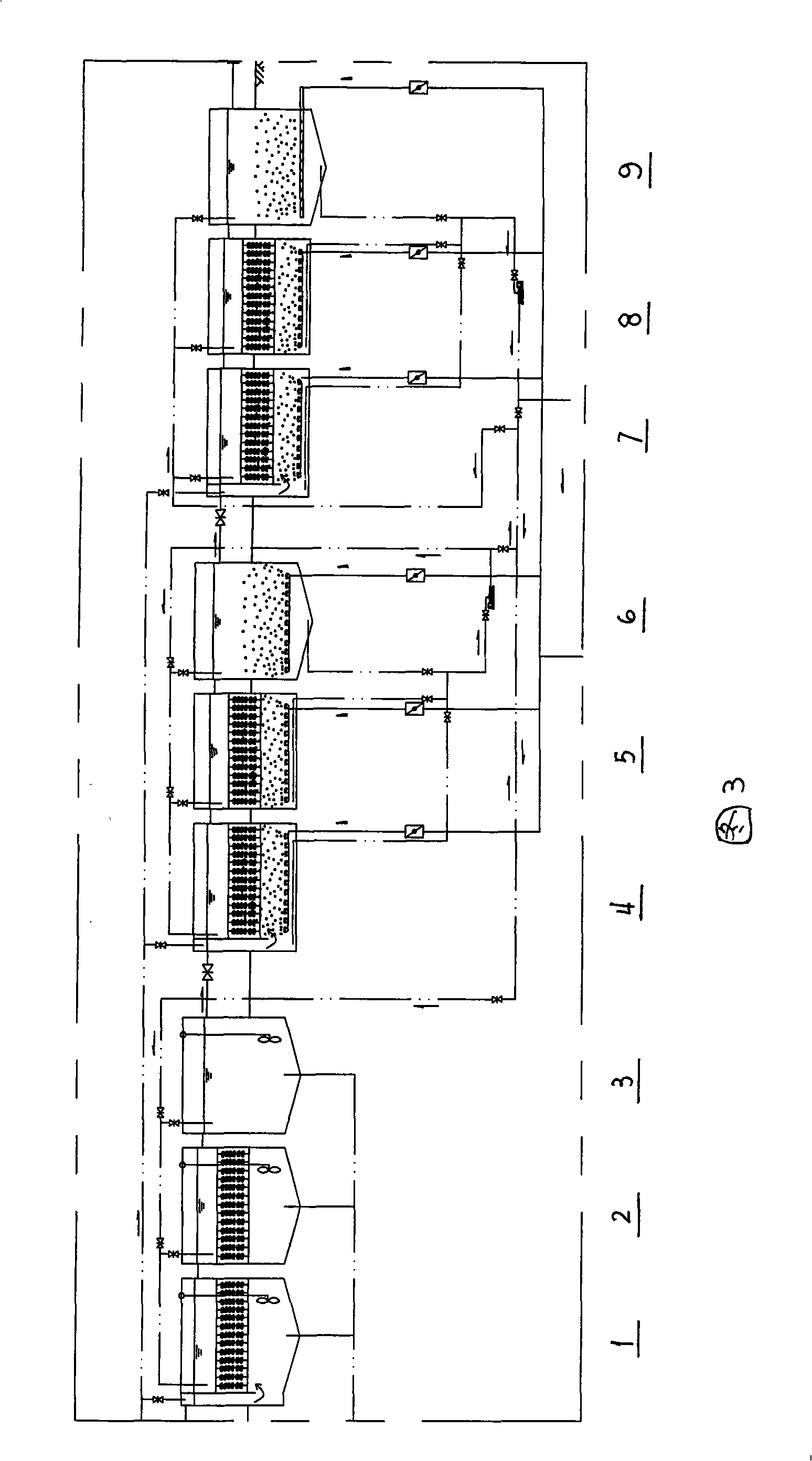

[0031] Figure 1, Figure 2 and Figure 3 show that the multi-stage reflux load control biological process supporting facilities and equipment include: flocculation sedimentation, neutralization and other pre-treatment processes; integrated biological pools; and post-treatment processes such as secondary sedimentation and air flotation. The industrial wastewater from the pre-treatment process enters the integrated biological pool, which is a collection of multi-stage biological treatment pools. It is divided into three stages, each stage has three stages, a total of nine stages, each stage has the same volume , and the same size;

[0032] The wastewater enters the first stage first, and its first and second stages are contact anaerobic pools 1 and 2 (also called hydrolytic acidification pools), and the pools are filled with high-density fillers to increase the biological treatment load; to increase its biological treatment load ; The microorganisms in the waste water adhere to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com