Preparation of high molecular weight high performance polylactic acid

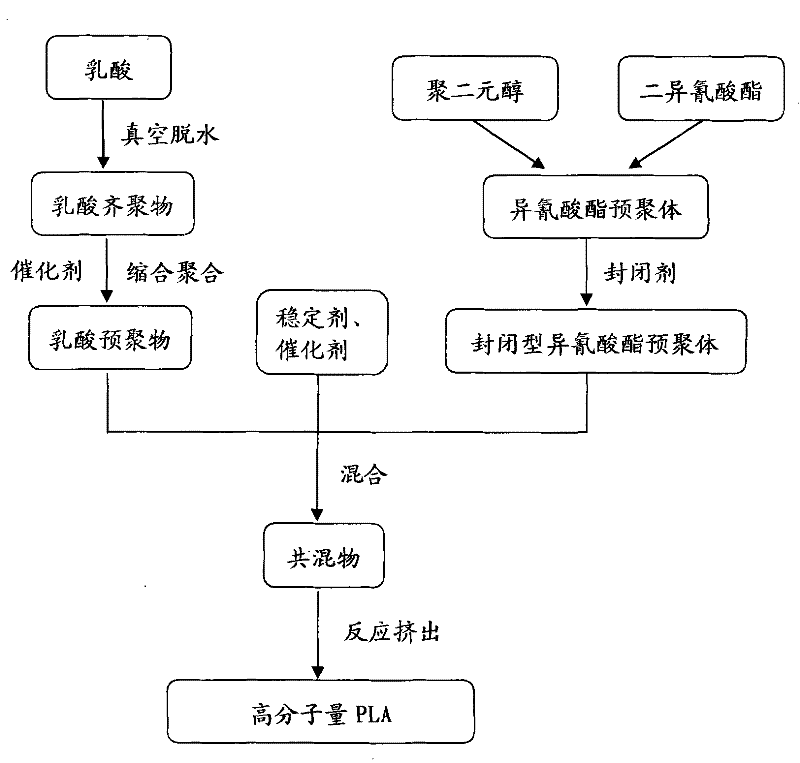

A high-molecular-weight, polylactic acid technology is applied in the field of preparation of high-molecular-weight polylactic acid to achieve the effects of improving product toughness, easy control of reaction conditions, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 500 g of D,L-lactic acid with a purity of 87% into a 1000 mL three-necked bottle equipped with a mechanical stirrer, and dehydrate at 110° C. for 1.5 h under an air pressure of 0.1 MPa. Add 3 g of antimony trioxide catalyst, stir well, replace the air in the three-necked bottle with nitrogen repeatedly, and react at 135°C for 10 h under the air pressure of 500 Pa. After purification, 310 g of PLA prepolymer with a weight average molecular weight of 38230 is obtained.

Embodiment 2

[0031] Add 2Kg of D,L-lactic acid with a purity of 87% into a 5L batch reactor equipped with a mechanical stirrer, and dehydrate at 100°C for 2h under an air pressure of 0.1MPa. Add 8g of antimony trioxide catalyst, stir well, replace the air in the kettle repeatedly with nitrogen, react at 140°C for 8h under the pressure of 1000Pa, and obtain 1.26Kg of prepolymer with a weight average molecular weight of 20050 after purification.

Embodiment 3

[0033] Add 9.6 g of toluene diisocyanate and 500 g of polyethylene glycol with a molecular weight of 20,000 into a 1000 mL three-necked bottle equipped with a mechanical stirrer, and react at 70° C. for 2.5 h under nitrogen protection. Add 2.7 g of methyl ethyl ketone oxime, and react at 85° C. for 3.5 h under the protection of nitrogen to obtain the prepared isocyanate prepolymer, which is milky white light yellow solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com