Patents

Literature

31results about How to "Easy to achieve large-scale continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

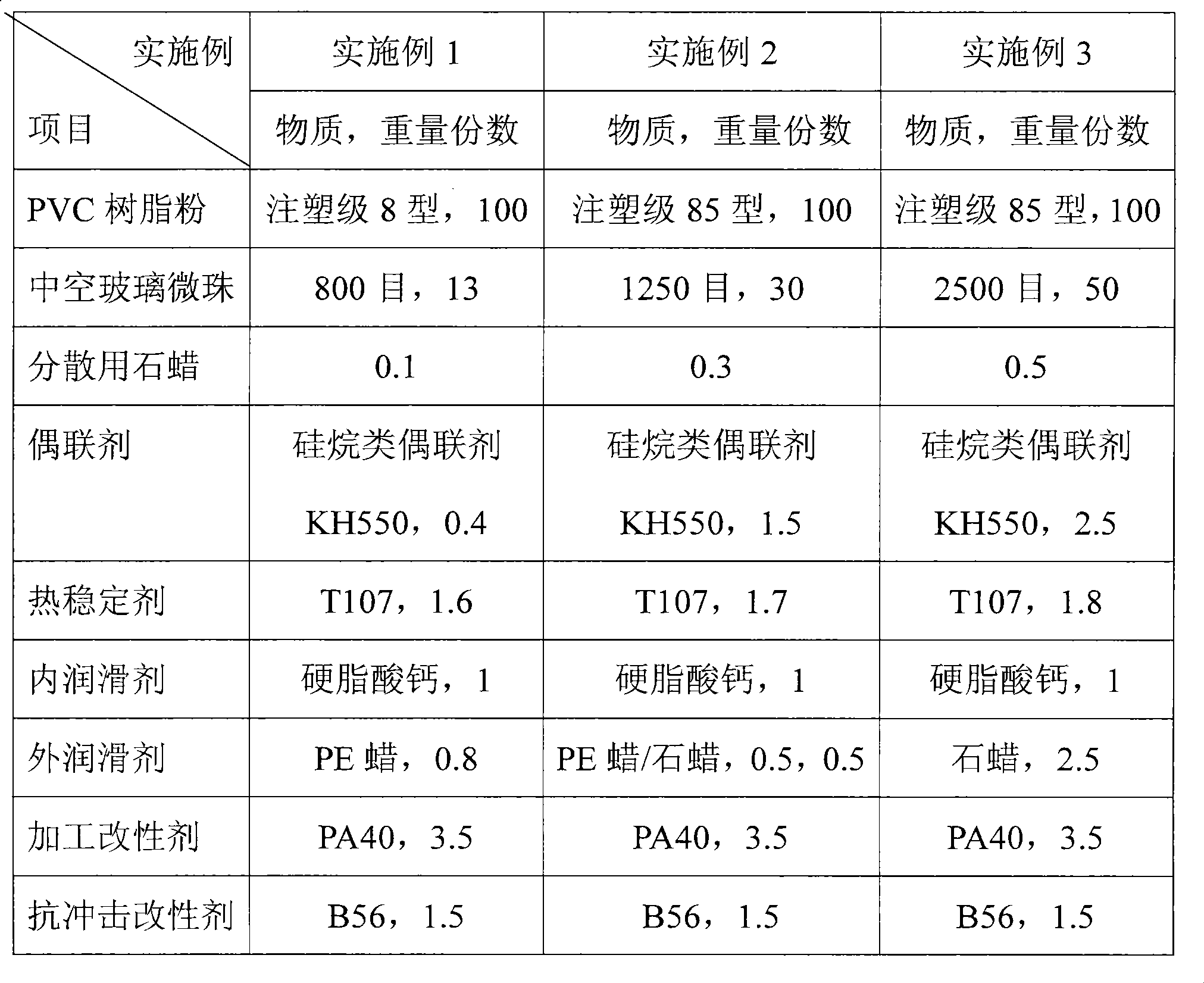

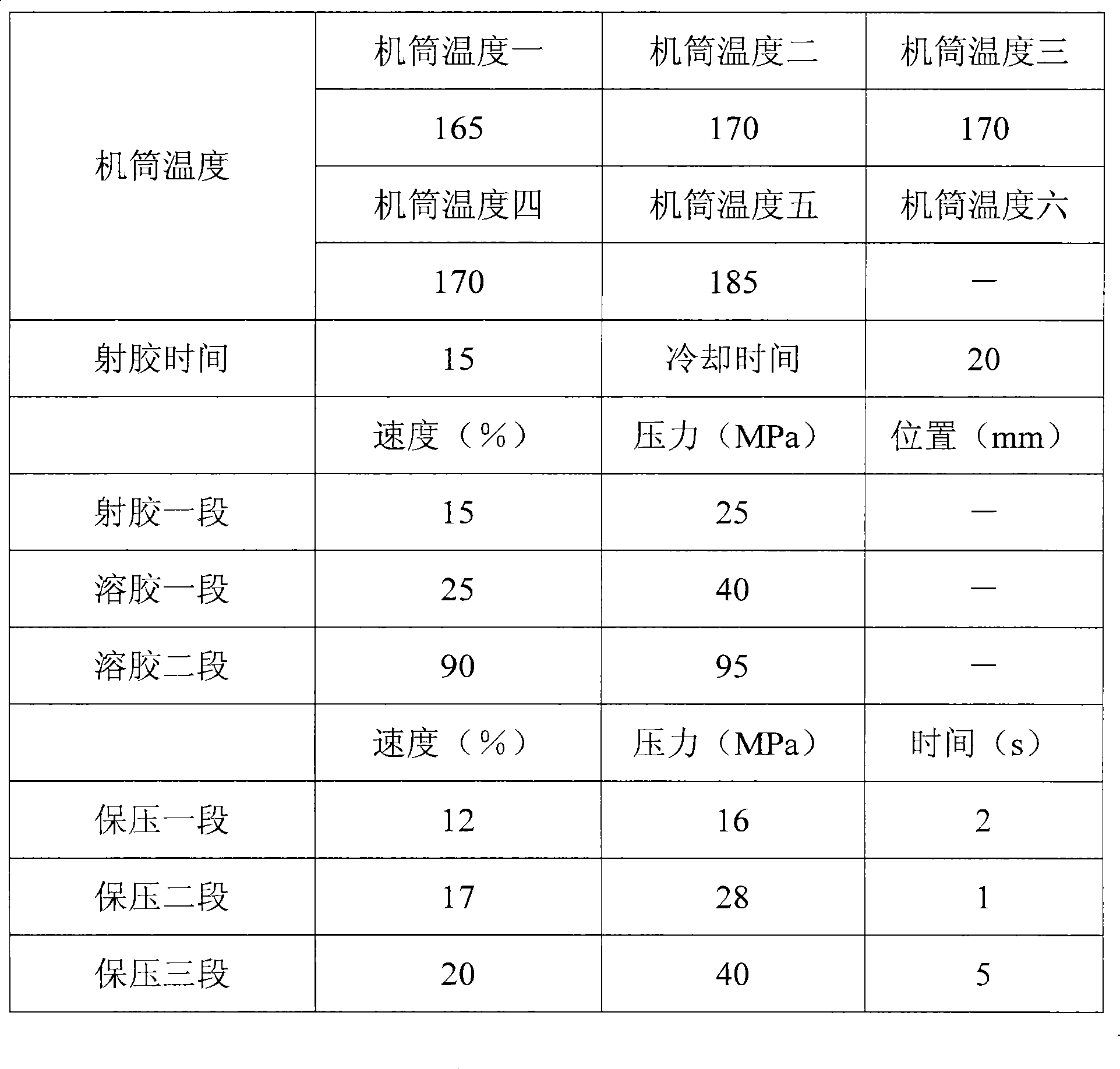

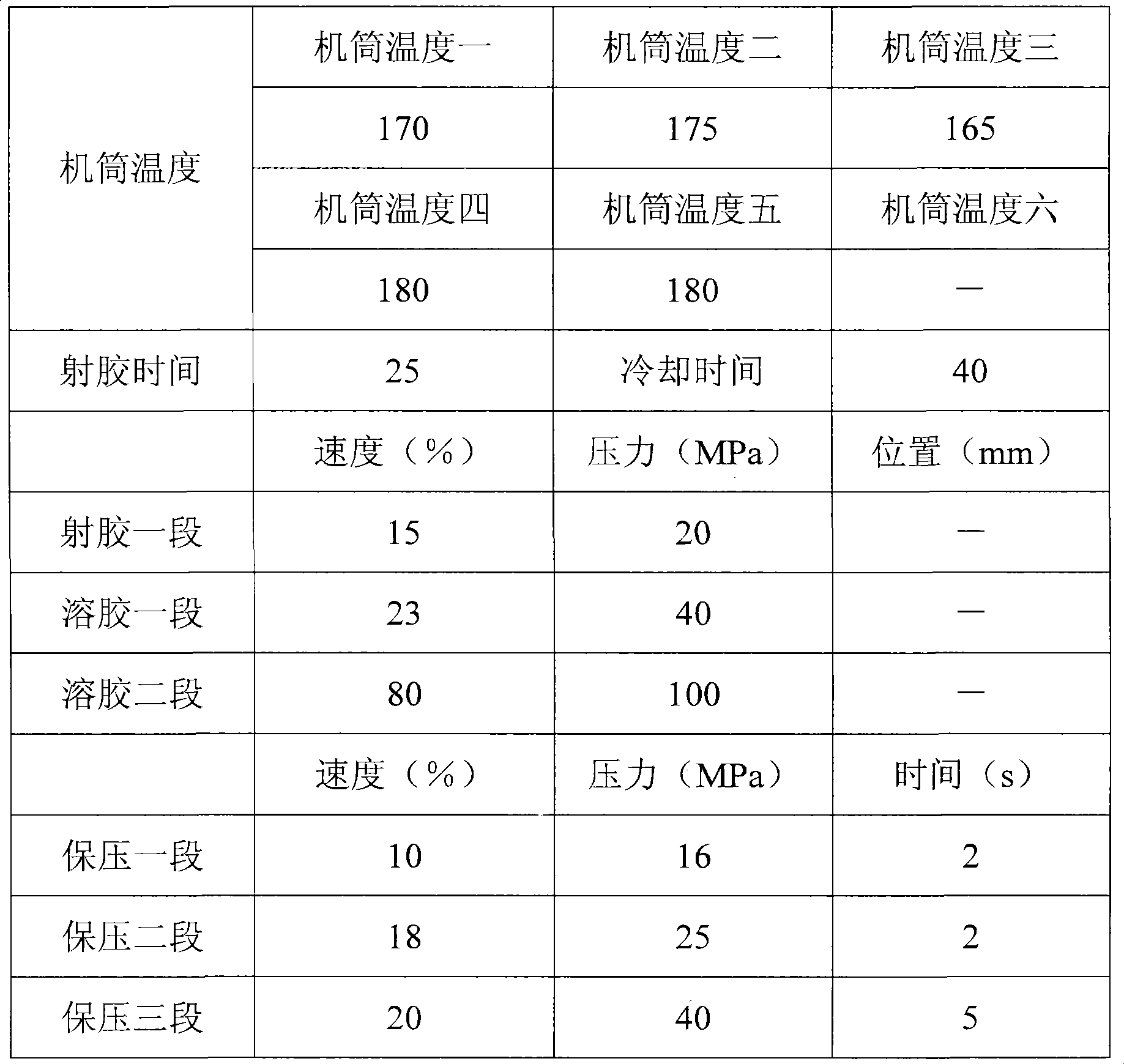

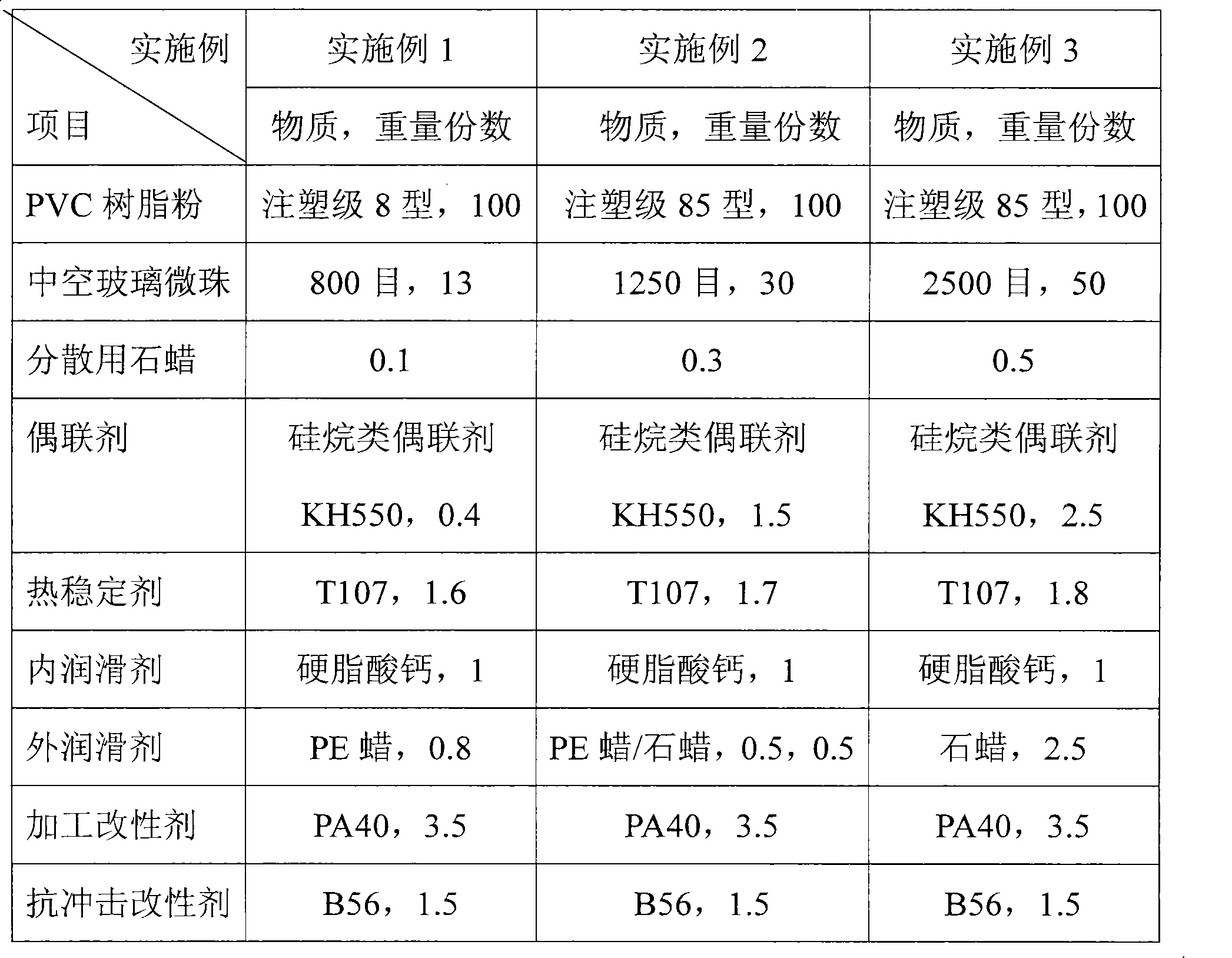

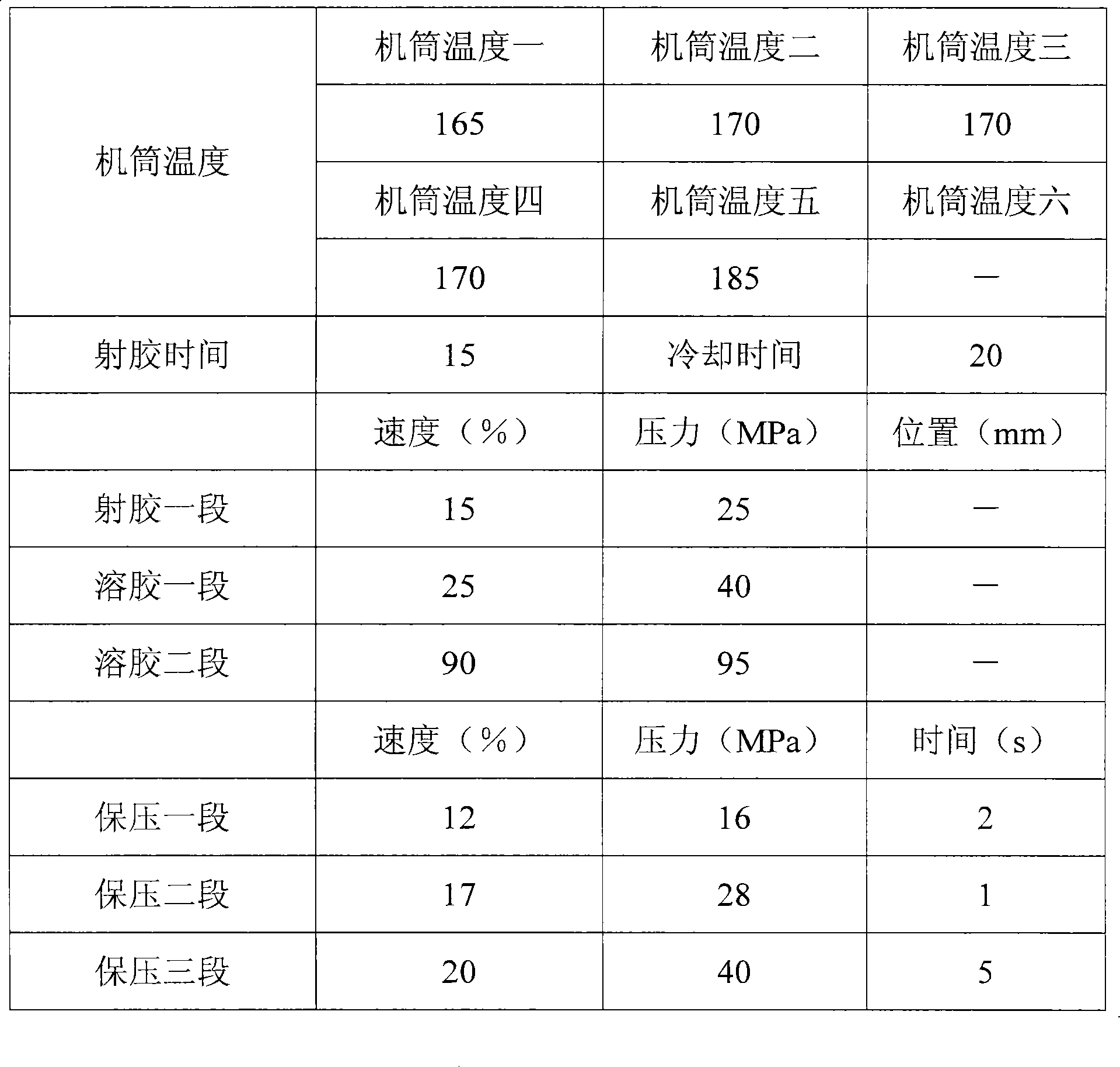

Hollow glass micro bead reinforcement rigid polyvinyl chloride material and preparation method thereof

The invention discloses a rigid polyvinyl chloride material reinforced by hollow glass microballoons and a preparation method thereof. The material comprises the following components in weight portion: 100 portions of polyvinyl chloride resin powder, 1 to 50 portions of the hollow glass microballoons, 0.1 to 10.0 portions of coupling agent, 0.5 to 3.0 portions of heat stabilizer, 0.2 to 5.0 portions of lubricant, 0.1 to 5.0 portions of processing modifier, and 0.1 to 10.0 portions of impact modifier. Through coupling compatibility and a distribution technology, the preparation method comprises the steps of compounding and directly injecting the hollow glass microballoons and the resin, and then processing the mixture to prepare the hollow glass microballoon reinforced rigid polyvinyl chloride material which has the advantages of higher impact resistance strength, hydraulic pressure resistance and explosion strength, higher size stability, and the like. The preparation method has the advantages that the preparation method uses simple and practicable processes to deal with compatibility problem, accords with design requirements of industrialized production processes at the same time of meeting requirements on product properties, can achieve large-scale continuous production, and has relatively low production cost and stronger industrialized popularization.

Owner:湖南联塑科技实业有限公司

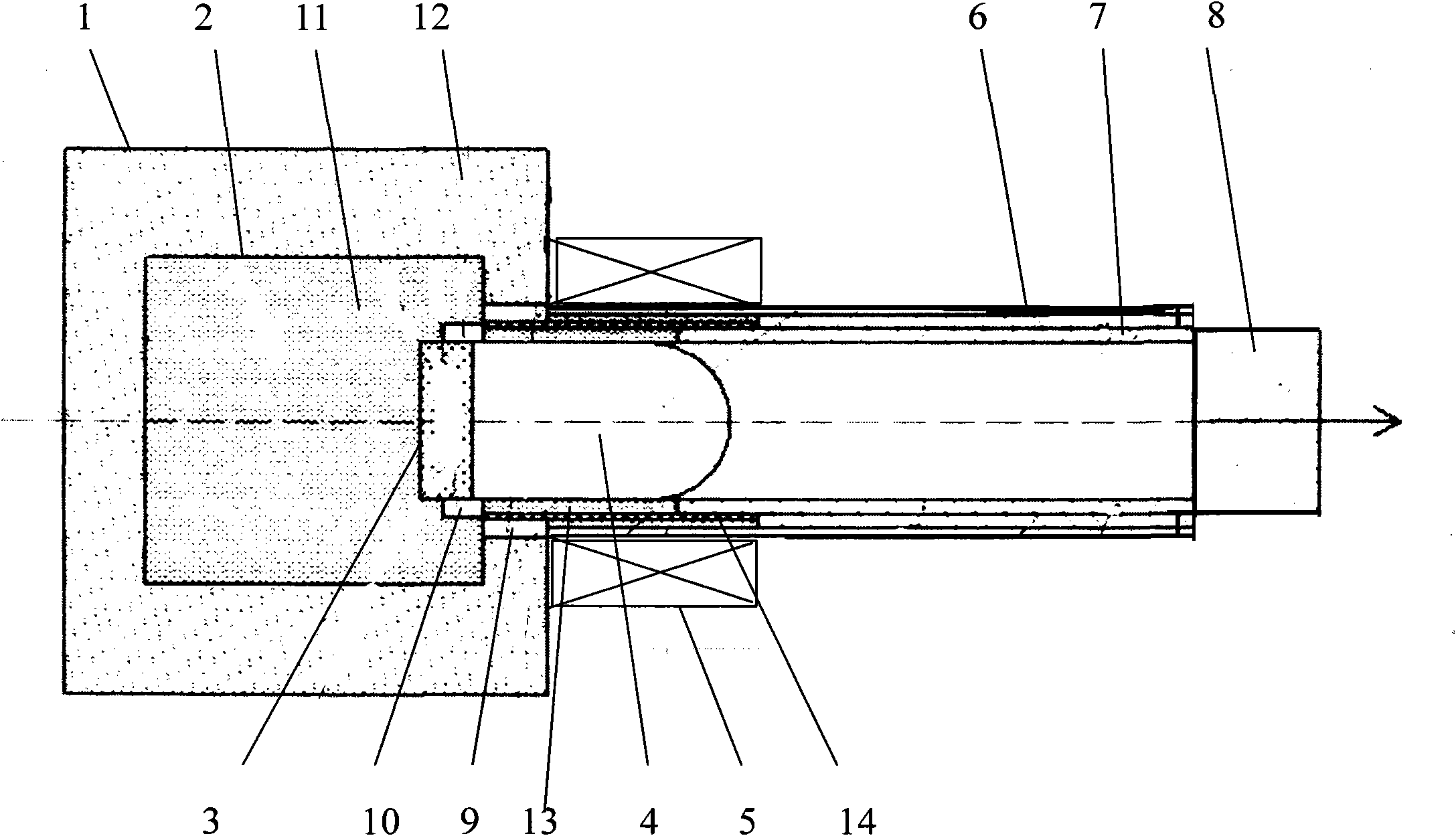

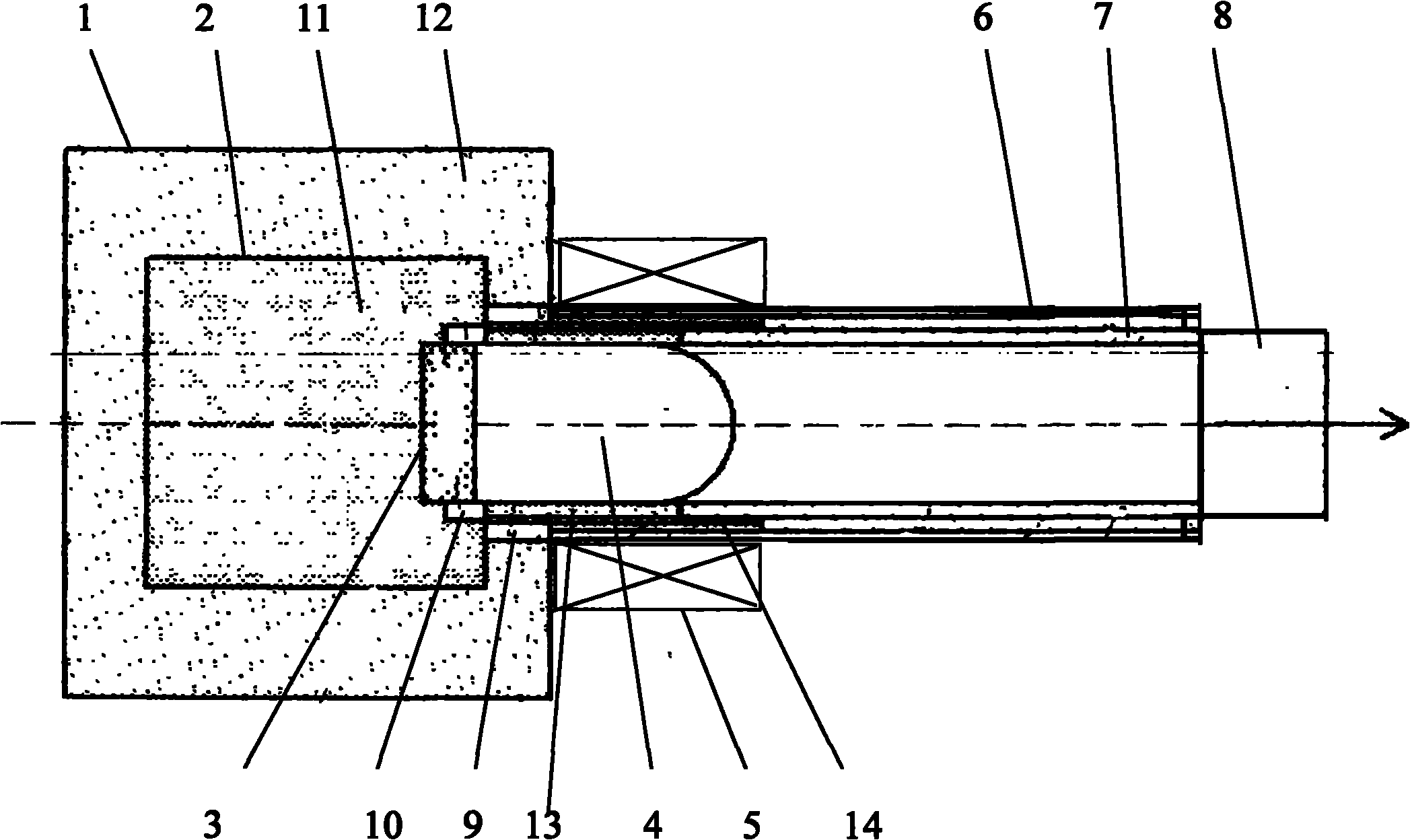

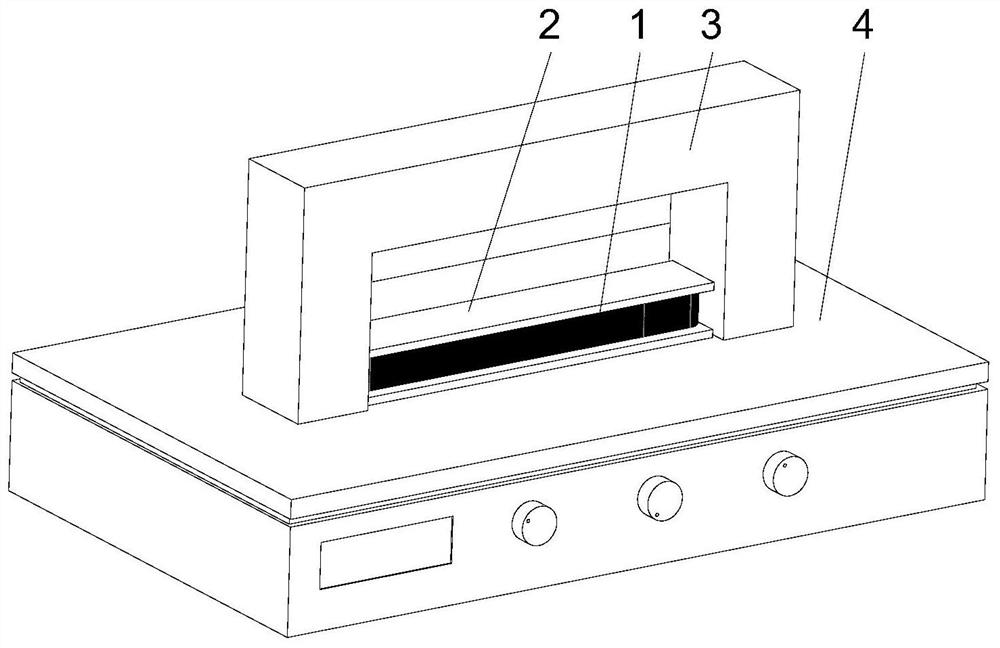

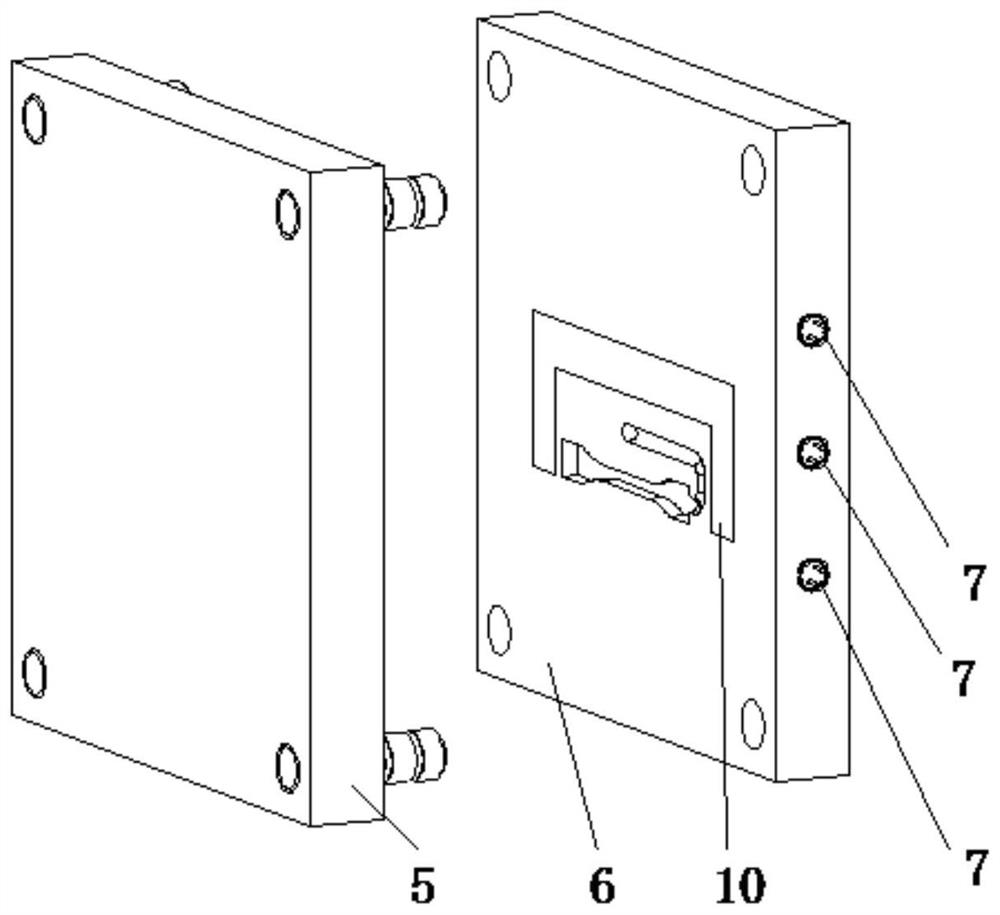

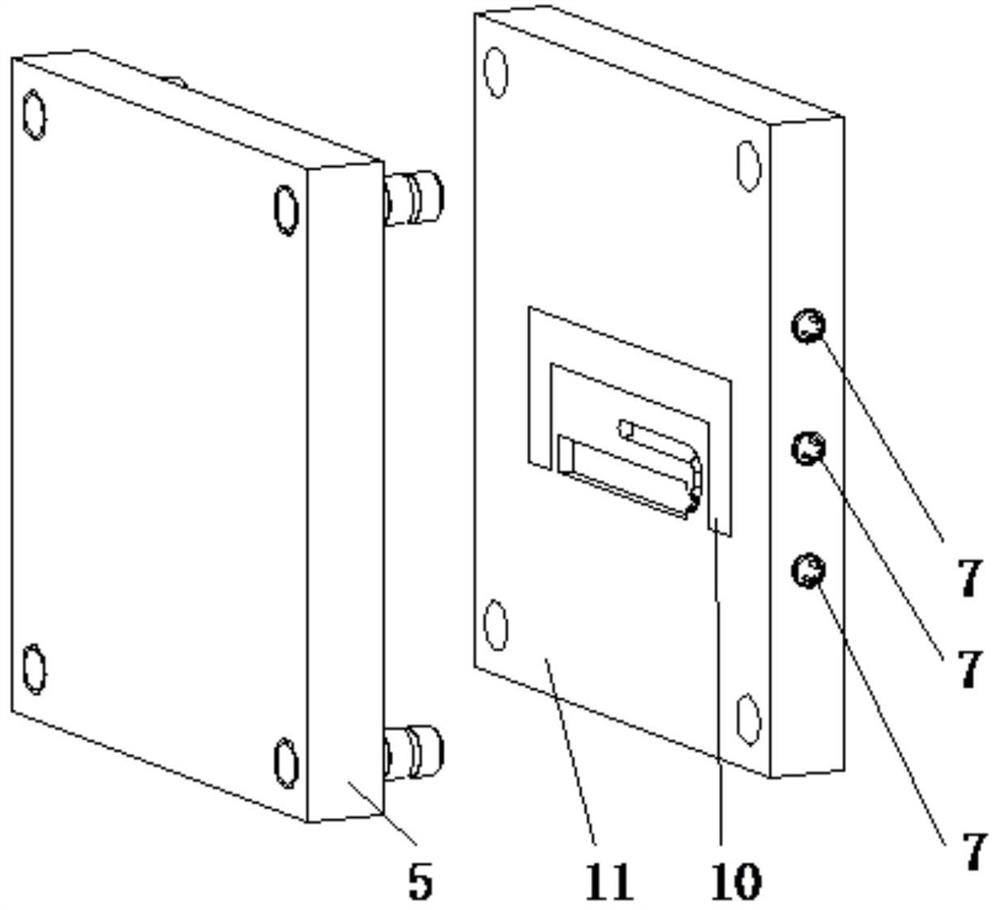

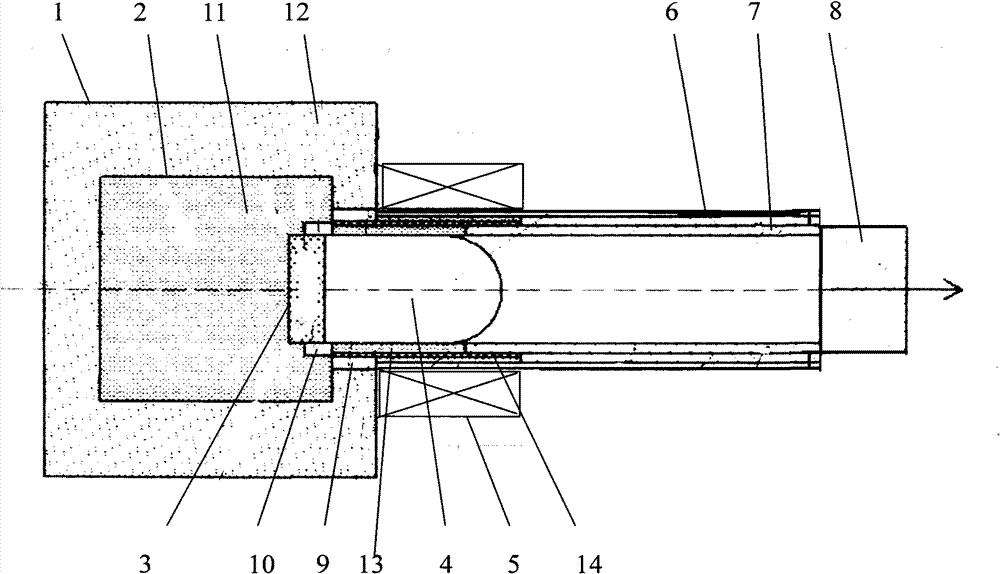

Composite pipe blank casting device and continuous casting method

The invention relates to a composite metal material casting device and a continuous casting method, in particular to a composite pipe blank casting device and a continuous casting method. The casting device is structurally characterized in that an external control valve is arranged at an outlet end of an external heat-insulation furnace, an internal control valve is arranged at an outlet end of an internal heat-insulation furnace, the internal heat-insulation furnace is communicated with a crystallizer by the internal control valve, a core head is arranged at the front end of the crystallizer, a pouring pipe is arranged on the outlet end of the external heat-insulation furnace, the core head is positioned in the pouring pipe, and the crystallizer and the external heat-insulation furnace are respectively communicated with the pouring pipe; the pouring pipe is internally provided with a traction pipe, the inner end of the traction pipe is plugged with the core head, and the outer end of the traction pipe is connected with a tractor; and an electromagnetism generator is arranged outside the pouring pipe. The continuous casting method includes the steps of melting and heat insulation of alloy blanks, electromagnetic continuous casting of a composite pipe blank, cutting of the pipe blank, and quality check of the composite pipe blank. In the invention, the technique process and the equipment are both simpler, large-scale continuous production can be easily realized, and the production cost of the composite pipe blanks can be greatly lowered.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP +1

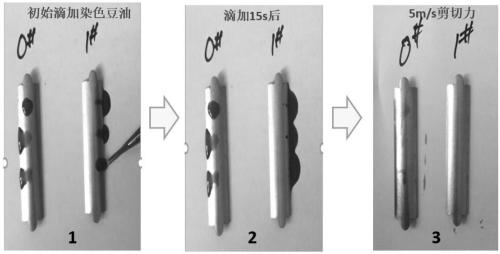

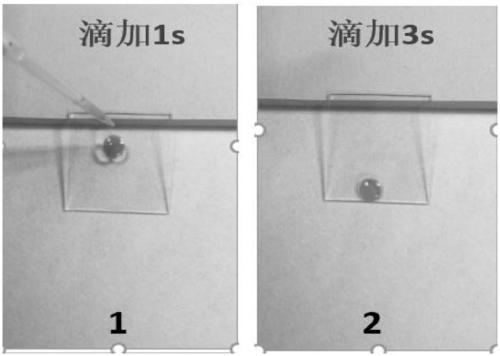

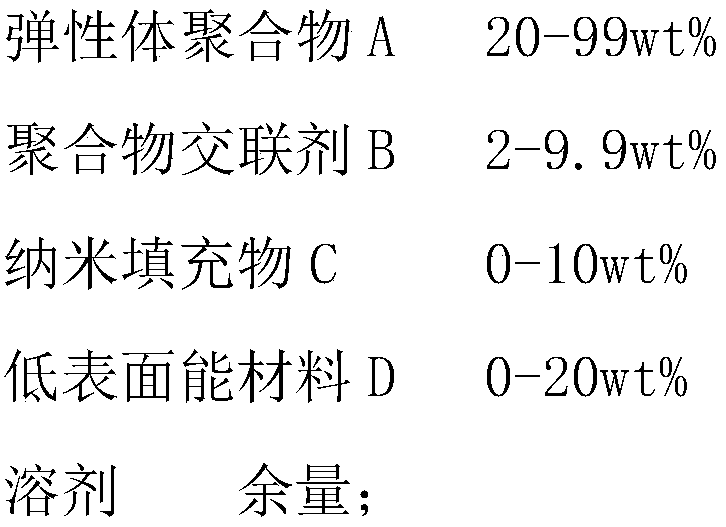

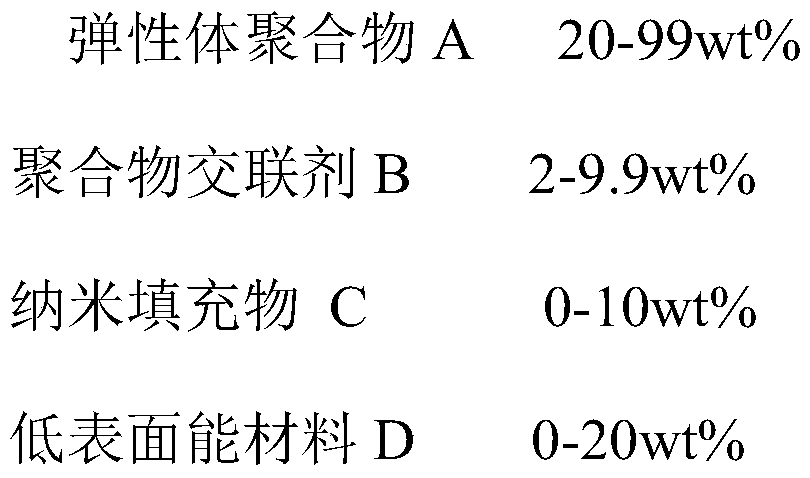

Oil adhesion-control antifouling self-cleaning fluoride-free coating and preparation method

ActiveCN109609028AHigh bonding strengthHigh hardnessAntifouling/underwater paintsPaints with biocidesCross-linkBasic research

The invention discloses an antifouling biomimetic coating with low adhesion of oil and fat and a preparation method of the antifouling biomimetic coating. Dolphin elastic skin is adopted as a basic research model of the coating, and the coating is obtained through crosslinking of polymer materials with a high elastic modulus and a low surface energy. Through control on the cross-linking density ofthe coating, change of low surface energy content and other parameter control, the adhesion resistance of the coating to various oil and low-surface-tension liquids is achieved. The coating has excellent oil adhesion resistance in both static and dynamic environments. The coating can be applied to multiple substrate surfaces, and can be applied to surfaces of various metals, ceramics, glass, various polymer materials and other materials, the adhesion between the coating and a substrate is high, and good transparency, flexibility, corrosion protection and other performance are achieved; and the coating is mainly applied to ventilation device blades, fume hood fan blade parts, smoke exhaust ventilator fan blade parts and other fan blade parts, and has a good application prospect and economic significance in reduction of surface oil stain and dust pollution, reduction of energy consumption, improvement of the work efficiency and reduction of energy consumption.

Owner:JILIN UNIV

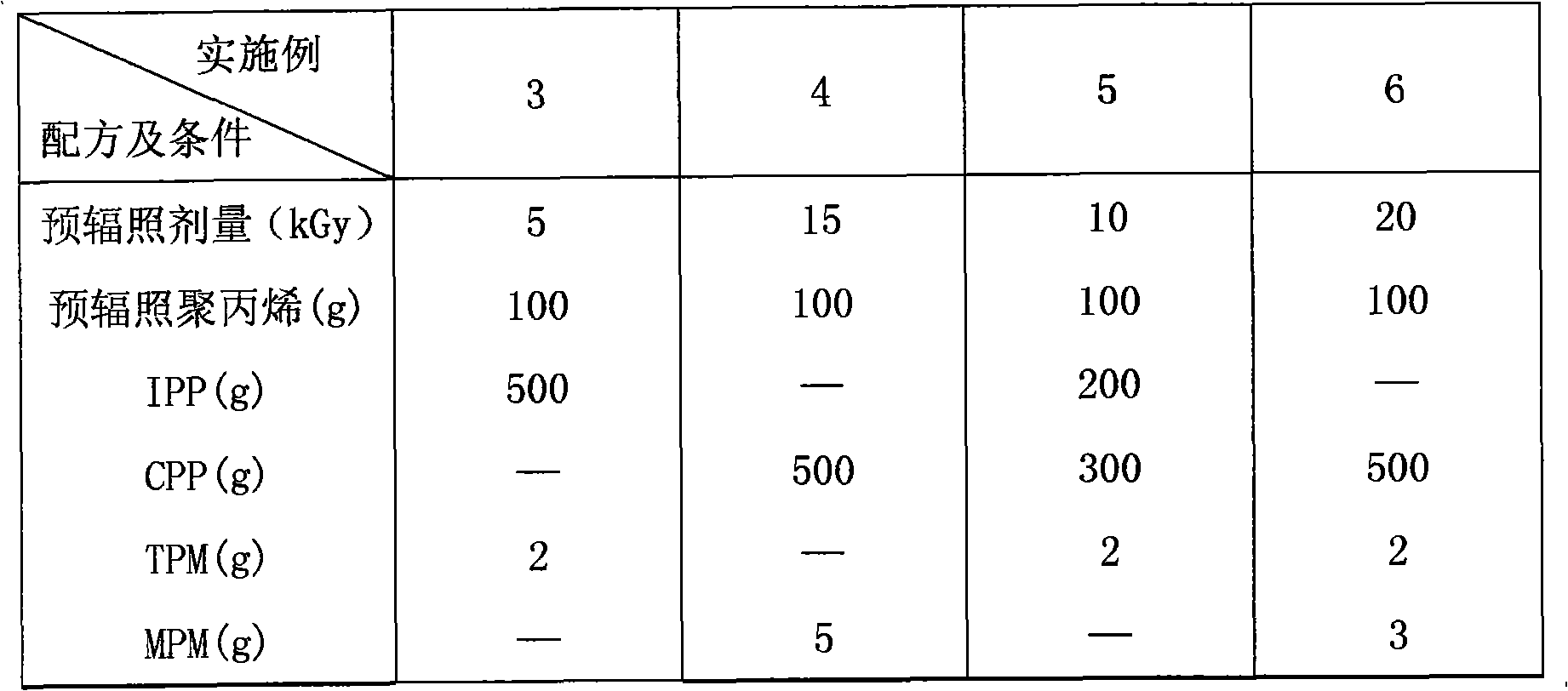

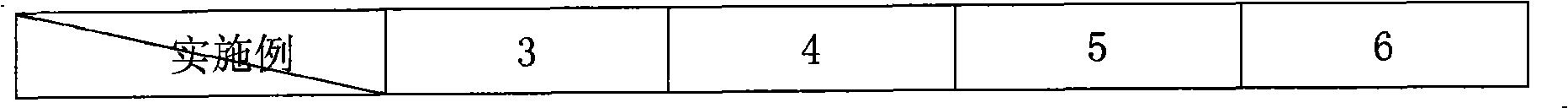

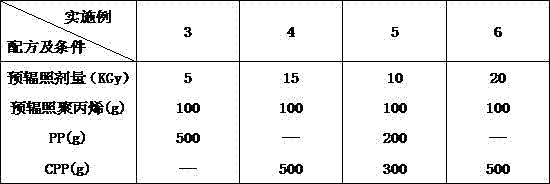

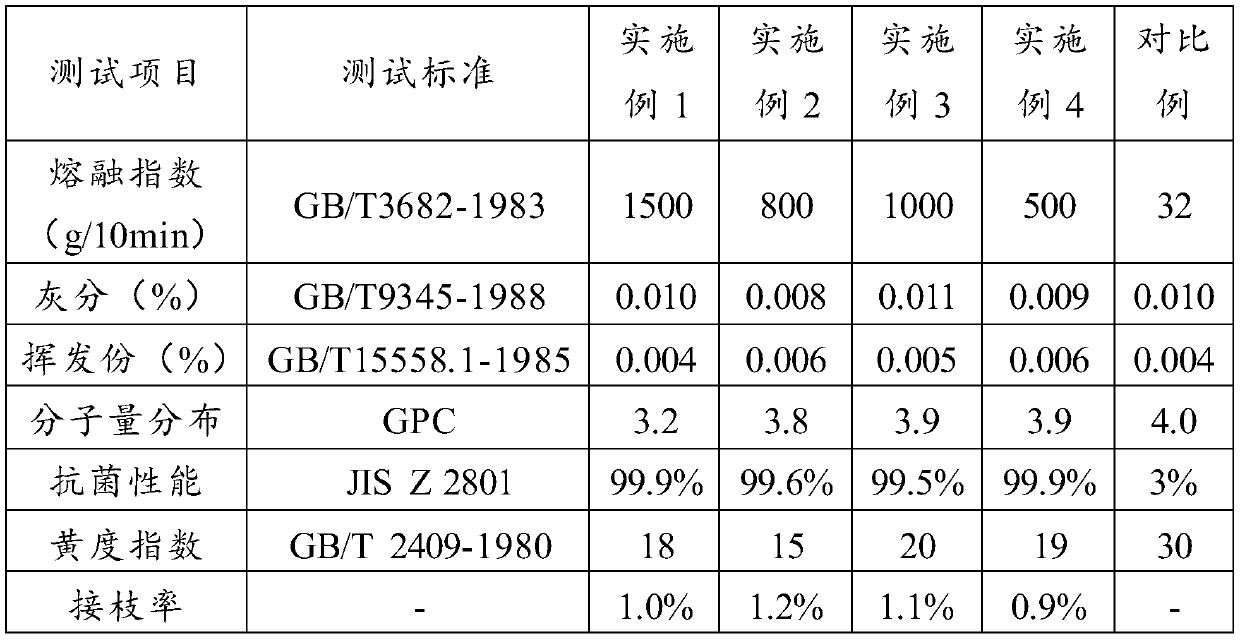

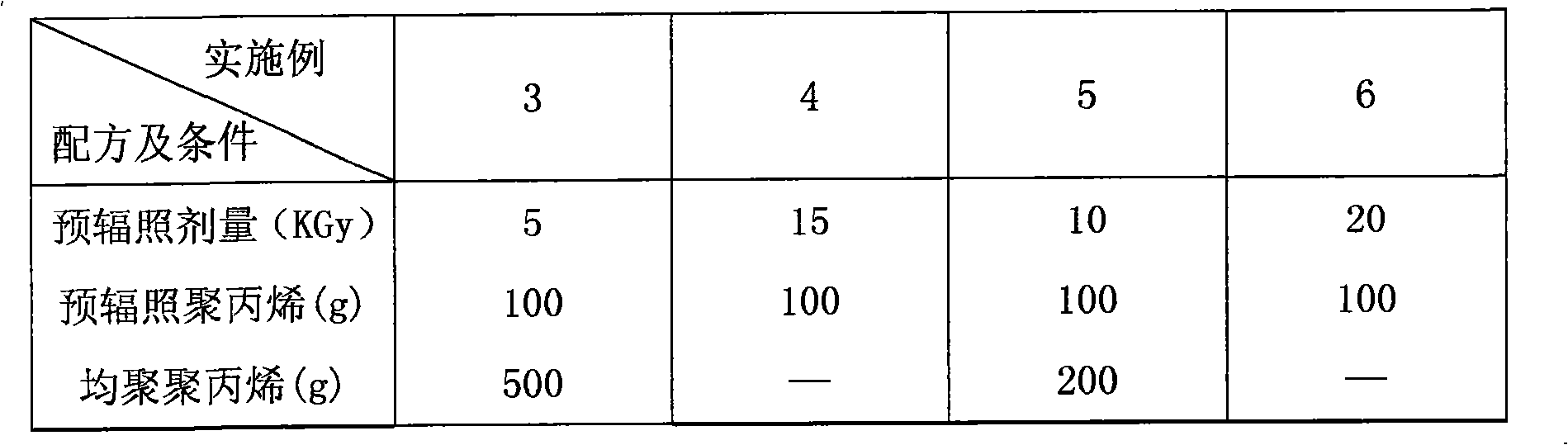

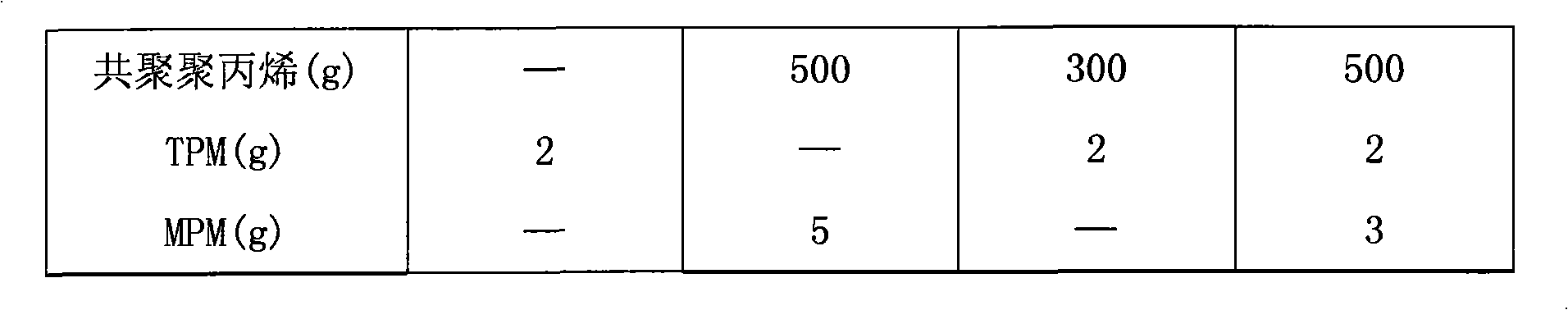

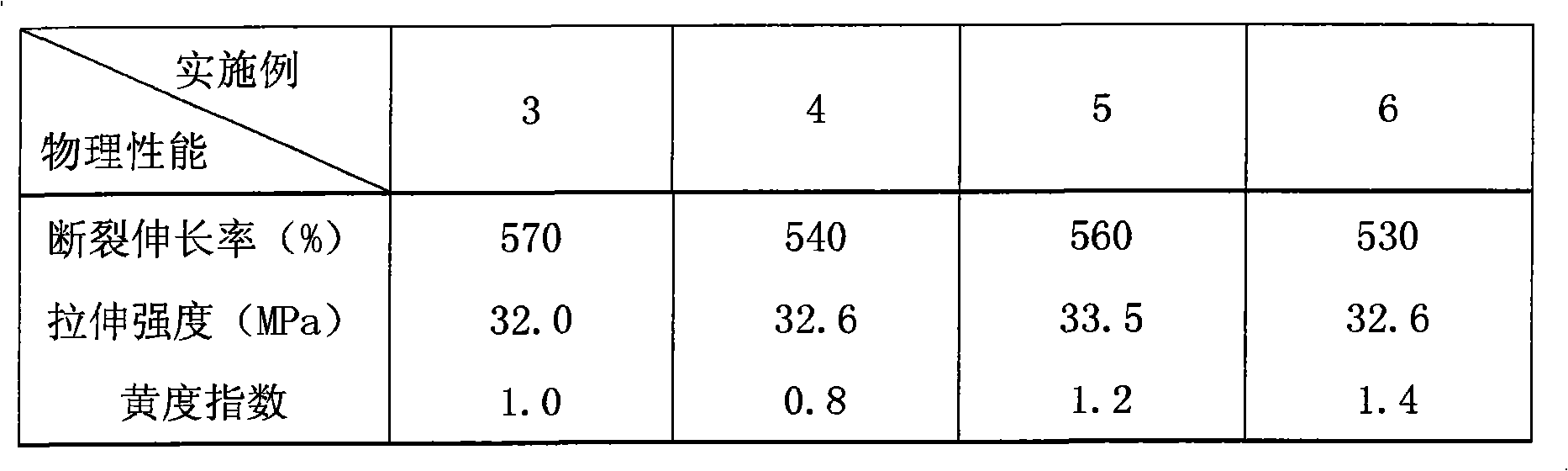

Method for preparing radiation aging resistant polypropylenes

ActiveCN101602872AEvenly dispersedNot easy to precipitateOrganic chemistryAging resistanceHindered amine light stabilizers

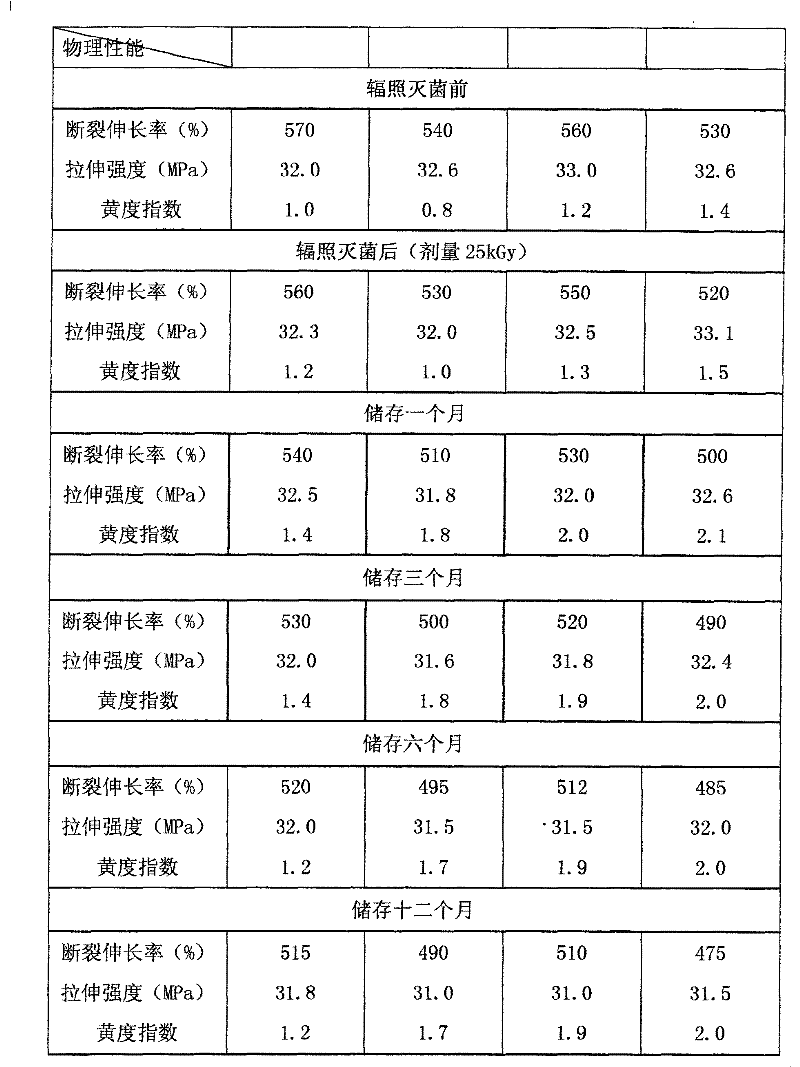

The invention discloses a method for preparing radiation aging resistant polypropylenes. Reactive hindered amine stabilizers are grafted on a polypropylene molecular chain by a reactive extrusion method to improve the aging resistance of materials after the polypropylenes are subjected to radiation treatment. Compared with radiation aging resistant polypropylenes prepared by the prior physical blending method, the radiation aging resistant polypropylenes have the advantages of uniform dispersion of the stabilizers, difficult precipitation, durable aging resistance and the like. The radiation aging resistant polypropylenes have the simple preparation method, have no pollution to the environment, and are easy to realize mass continuous production. The radiation aging resistant polypropylenes prepared by the method can be applied in fields such as medical infusion instruments, food packaging, medicament packaging and the like; and after a radiation sterilization method is adopted for sterilization and within one year of storage period, the elongation at break of products is reduced and is less than 50 percent, the tensile strength is reduced and is less than 2MPa, and the yellowness index is increased and is less than 1. Therefore, the radiation aging resistant polypropylenes have strong radiation aging resistance.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

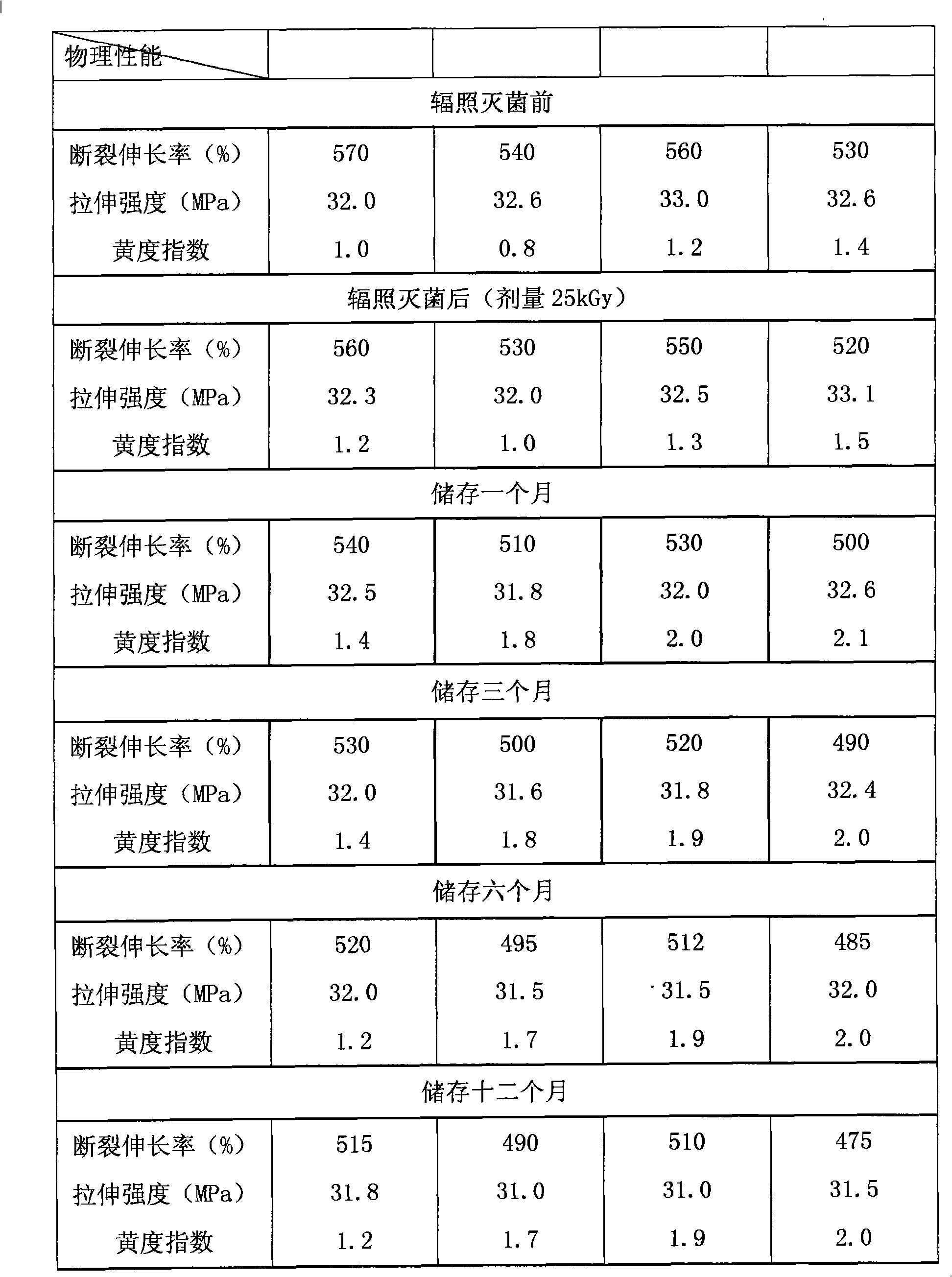

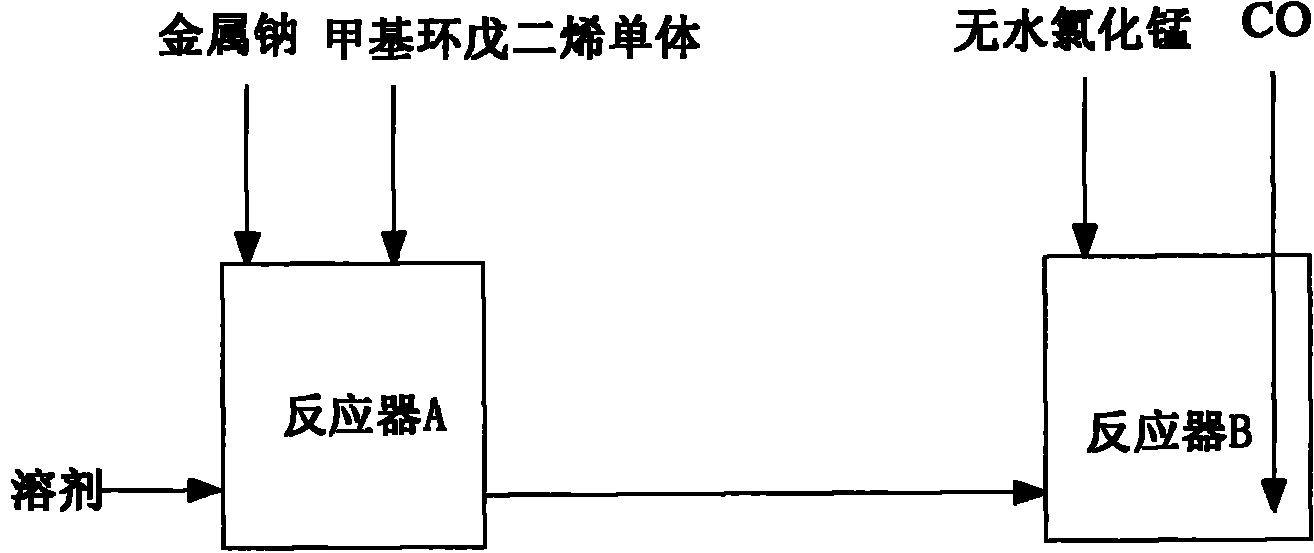

Method for preparing methyl cyclopentadienyl tricarbonyl manganese through continuous reaction

The invention provides a method for preparing methyl cyclopentadienyl tricarbonyl manganese through continuous reaction. The method comprises the following steps of: (1) continuously adding methyl cyclopentadiene monomer and metal sodium into a reactor A in which a dehydration solvent is held; and (2) continuously feeding feed liquor into a reactor B from the reactor A, continuously adding anhydrous manganese chloride into the reactor B, and introducing CO gas into the reactor B to perform reaction. The method has the obvious advantages of full reaction, less byproducts, high yield and easiness in large-scale industrialization due to adoption of continuous reaction in an entire reaction process.

Owner:HEBEI HUAGE FINE CHEM

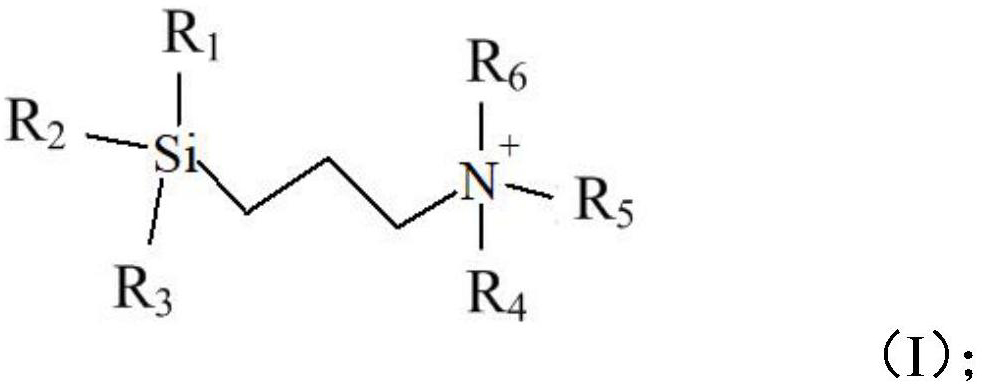

High polymer material surface anticoagulation modification method

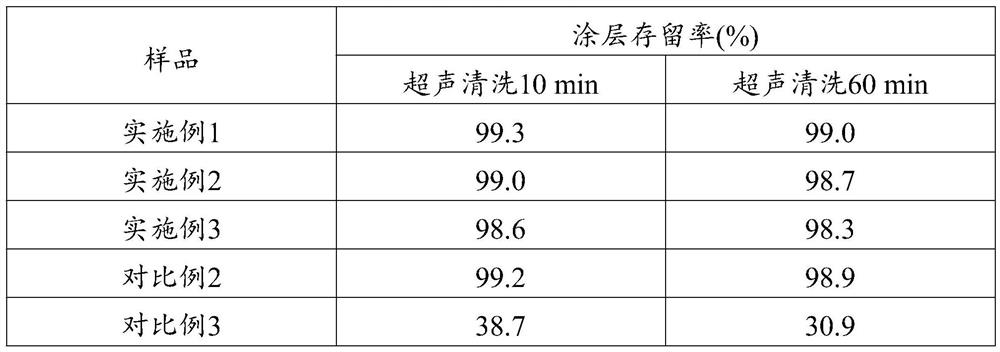

ActiveCN111635549AImprove stain resistanceImprove stabilityHeparin coatingsAlginic acid coatingsPlasma activationAqueous solution

The invention relates to the technical field of medical polymer materials and medical instruments, in particular to a high polymer material surface anticoagulation modification method. The high polymer material surface anticoagulation modification method comprises the following steps: A) performing low-temperature plasma activation treatment on the high polymer material; b) putting the activated high polymer material into an organic solution containing a charge compound for 0.5-10 minutes, taking out, and drying to obtain a high polymer material coated with the charge compound, wherein the charge compound is prepared from raw materials including sodium alginate and organosilicon quaternary ammonium salt; and C) placing the high polymer material coated with the charge compound in an aqueoussolution of heparin sodium for 0.5-10 min, taking out the high polymer material, and heating the high polymer material at 40-80 DEG C to obtain the high polymer material containing the anticoagulation coating. The anticoagulation coating obtained by the high polymer material surface anticoagulation modification method is not liable to fall off, and the anticoagulation effect is better.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Environment-friendly polypropylene melt-blown material and preparation method thereof

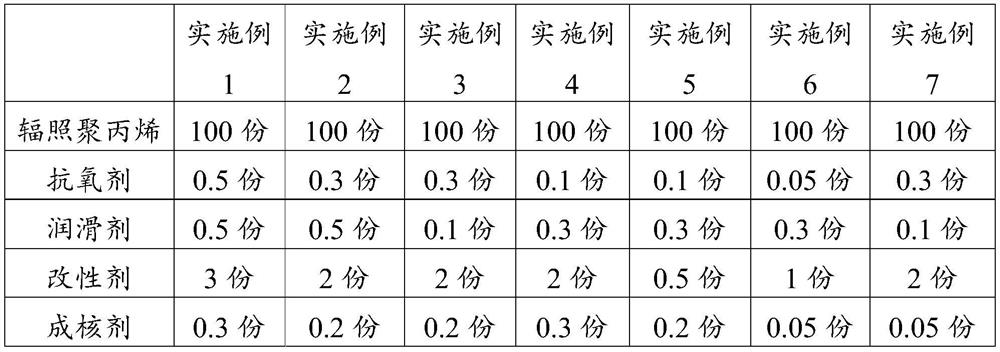

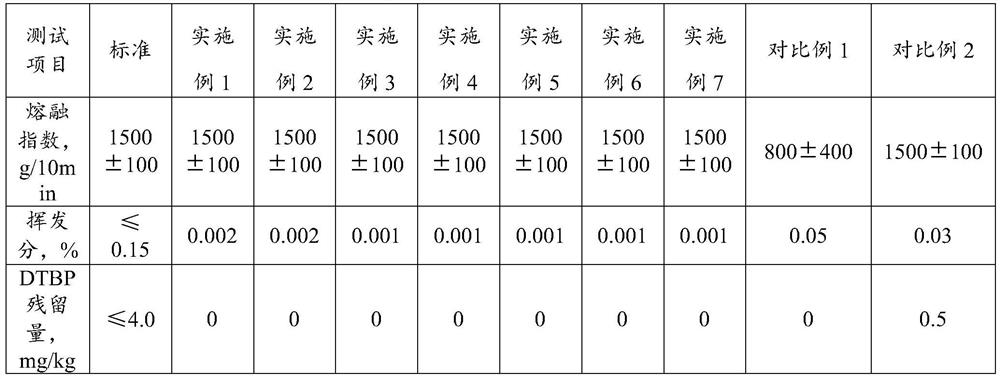

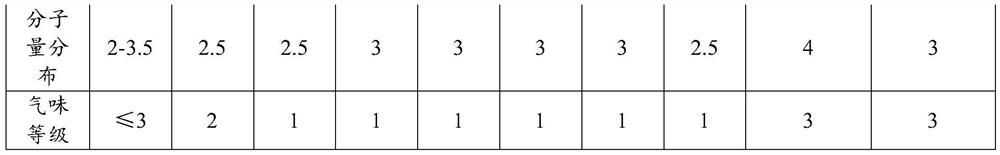

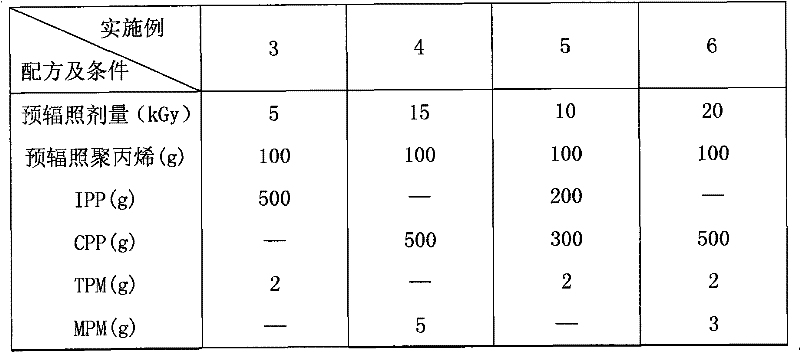

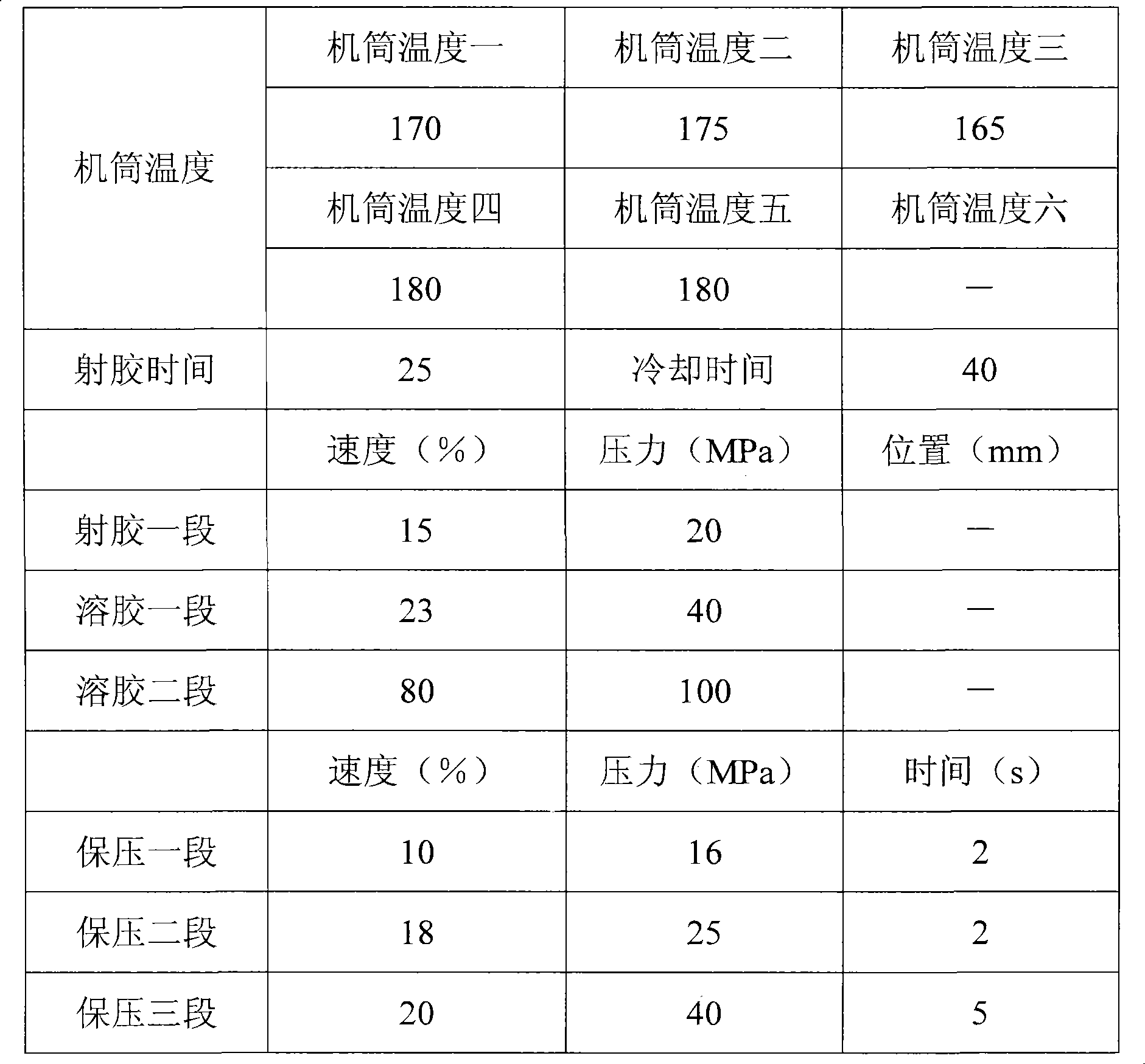

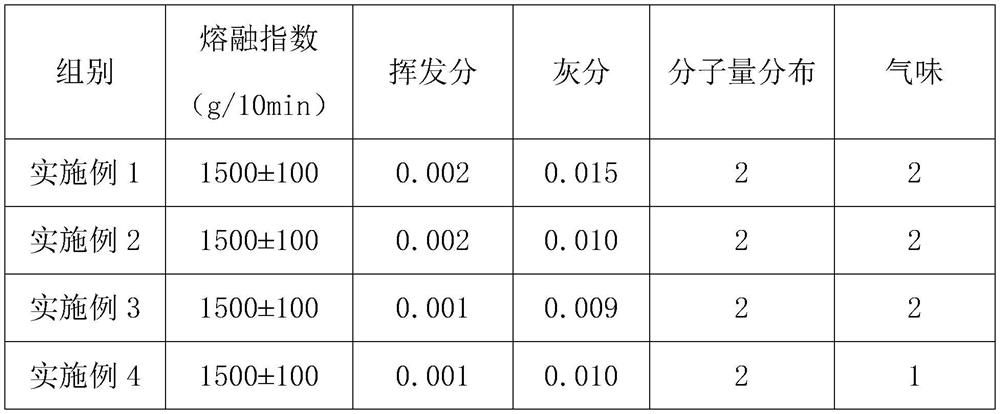

The invention discloses an environment-friendly polypropylene melt-blown material and a preparation method thereof. The environment-friendly polypropylene melt-blown material is prepared from the following raw materials in parts by weight: 100 parts of irradiated polypropylene; 0.05 to 0.5 part of an antioxidant; 0.1 to 0.5 part of a lubricant; 0.5 to 3 parts of a modifier; and 0.05 to 0.3 part ofa nucleating agent. The irradiated polypropylene is obtained by sequentially carrying out first irradiation treatment, extrusion granulation treatment and second irradiation treatment on polypropylene. According to the technical scheme, the irradiated polypropylene, the antioxidant, the lubricant, the modifier and the nucleating agent are adopted as raw materials, the ratio of the raw materials is reasonably set, the raw materials are matched with one another, an unexpected technical effect is achieved, and the obtained environment-friendly polypropylene melt-blown material meets the specialmaterial standard of T / SGX 001-2020 Special Polypropylene (PP) Material for Melt-blown Medical Masks, and has the characteristics of stable quality, low odor, low VOC content, narrow molecular weightdistribution and high melt index (up to 1500+ / -100g / 10min or above).

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Preparation method of composite conductive shielding materials

InactiveCN102373446ALess investmentLow running costLiquid/solution decomposition chemical coatingPolyesterChemical solution

The invention provides a preparation method of composite conductive shielding materials, which completely adopts a chemical deposition method for preparation. The method has the obvious advantages that the flow process is short, the cost is low, and the environment is protected. The method adopts the following technical scheme that the preparation method of the composite conductive shielding materials is characterized in that a copper layer and a silver layer are coated and plated on the surface of polyester or polyamide nonconductive materials by the chemical deposition method. The method has the process flow that the surface chemical pretreatment, the chemical copper plating, the water cleaning, the chemical silver plating and the color degradation prevention treatment are carried out on the surfaces of the polyester or polyamide nonconductive materials, the chemical pretreatment process is carried out in chemical solution containing 8 to 15ml / l of hydrochloric acid, 0.1 to 0.6g / l of palladium chloride and 10 to 16g / l of stannous chloride, the treatment time is 10 to 15min, and the treatment temperature is 20 to 35 DEG C.

Owner:山东中特防科技发展有限公司

Environment-friendly bamboo-plastic automobile instrument and manufacturing method thereof

The invention discloses an environment-friendly bamboo-plastic automobile instrument and a manufacturing method thereof. The environment-friendly bamboo-plastic automobile instrument comprises the following components in parts by weight: 100 parts of polypropylene, 20-30 parts of polyolefin elastomer, 20-40 parts of bamboo fibers and 0.4-0.8 part of a modifying agent. The environment-friendly bamboo-plastic automobile instrument disclosed by the invention is good in forming processability and mechanical performances. According to the environment-friendly bamboo-plastic automobile instrument and the manufacturing method thereof, the pure natural bamboo fibers are used as materials for reducing the using amount of the plastic material, so that the environment-friendly bamboo-plastic automobile instrument is green and environment-friendly; moreover, the manufacturing method is simple and easy to realize large-scale continuous production. The bamboo fibers are added, so that the environment-friendly bamboo-plastic automobile instrument has excellent antibacterial performances.

Owner:SHANGHAI HAN MOLDING SHAPE CO LTD

Method for preparing radiation aging resistant polypropylenes

ActiveCN101602872BEvenly dispersedNot easy to precipitateOrganic chemistryAging resistanceHindered amine light stabilizers

The invention discloses a method for preparing radiation aging resistant polypropylenes. Reactive hindered amine stabilizers are grafted on a polypropylene molecular chain by a reactive extrusion method to improve the aging resistance of materials after the polypropylenes are subjected to radiation treatment. Compared with radiation aging resistant polypropylenes prepared by the prior physical blending method, the radiation aging resistant polypropylenes have the advantages of uniform dispersion of the stabilizers, difficult precipitation, durable aging resistance and the like. The radiation aging resistant polypropylenes have the simple preparation method, have no pollution to the environment, and are easy to realize mass continuous production. The radiation aging resistant polypropylenes prepared by the method can be applied in fields such as medical infusion instruments, food packaging, medicament packaging and the like; and after a radiation sterilization method is adopted for sterilization and within one year of storage period, the elongation at break of products is reduced and is less than 50 percent, the tensile strength is reduced and is less than 2MPa, and the yellowness index is increased and is less than 1. Therefore, the radiation aging resistant polypropylenes have strong radiation aging resistance.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Hollow glass micro bead reinforcement rigid polyvinyl chloride material and preparation method thereof

The invention discloses a rigid polyvinyl chloride material reinforced by hollow glass microballoons and a preparation method thereof. The material comprises the following components in weight portion: 100 portions of polyvinyl chloride resin powder, 1 to 50 portions of the hollow glass microballoons, 0.1 to 10.0 portions of coupling agent, 0.5 to 3.0 portions of heat stabilizer, 0.2 to 5.0 portions of lubricant, 0.1 to 5.0 portions of processing modifier, and 0.1 to 10.0 portions of impact modifier. Through coupling compatibility and a distribution technology, the preparation method comprises the steps of compounding and directly injecting the hollow glass microballoons and the resin, and then processing the mixture to prepare the hollow glass microballoon reinforced rigid polyvinyl chloride material which has the advantages of higher impact resistance strength, hydraulic pressure resistance and explosion strength, higher size stability, and the like. The preparation method has the advantages that the preparation method uses simple and practicable processes to deal with compatibility problem, accords with design requirements of industrialized production processes at the same timeof meeting requirements on product properties, can achieve large-scale continuous production, and has relatively low production cost and stronger industrialized popularization.

Owner:湖南联塑科技实业有限公司

Radiation-resistant PP electret melt-blown material and preparation process thereof

PendingCN114044973AGood flexibilityDoes not affect filtration efficiencyConjugated synthetic polymer artificial filamentsArtifical filament manufactureUv absorbancePolymer science

The invention relates to the technical field of melt-blown material preparation, and particularly discloses an irradiation-resistant PP (polypropylene) electret melt-blown material and a preparation process thereof. The melt-blown material is prepared from the following components in parts by weight: 80 to 100 parts of polypropylene resin, 10 to 20 parts of polylactic acid, 2 to 8 parts of electret master batch, 0.2 to 0.6 part of an antibacterial agent, 0.01 to 0.05 part of a nucleating agent, 1 to 4 parts of an antioxidant, 0.2 to 0.8 part of a lubricating agent, 0.1 to 0.5 part of an ultraviolet absorbent and 0.01 to 0.08 part of a light stabilizer, wherein the electret master batch is prepared from the following components in parts by weight: 50 to 80 parts of homo-polypropylene resin, 10 to 15 parts of modified nano silicon dioxide, 12 to 18 parts of modified nano white carbon black, 1 to 5 parts of an accelerant Tac and 1 to 9 parts of an electret agent. The defects in the prior art are overcome, the flexibility of the polypropylene melt-blown material is improved by adding the polylactic acid into the polypropylene resin, the filtering efficiency of the polypropylene melt-blown material is not influenced, the reaction is thorough, the molecular weight distribution is narrow, and the melt index is uniform.

Owner:中核同辐(长春)辐射技术有限公司 +1

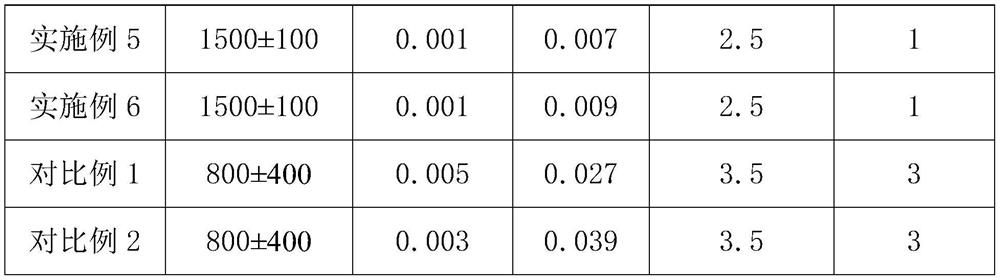

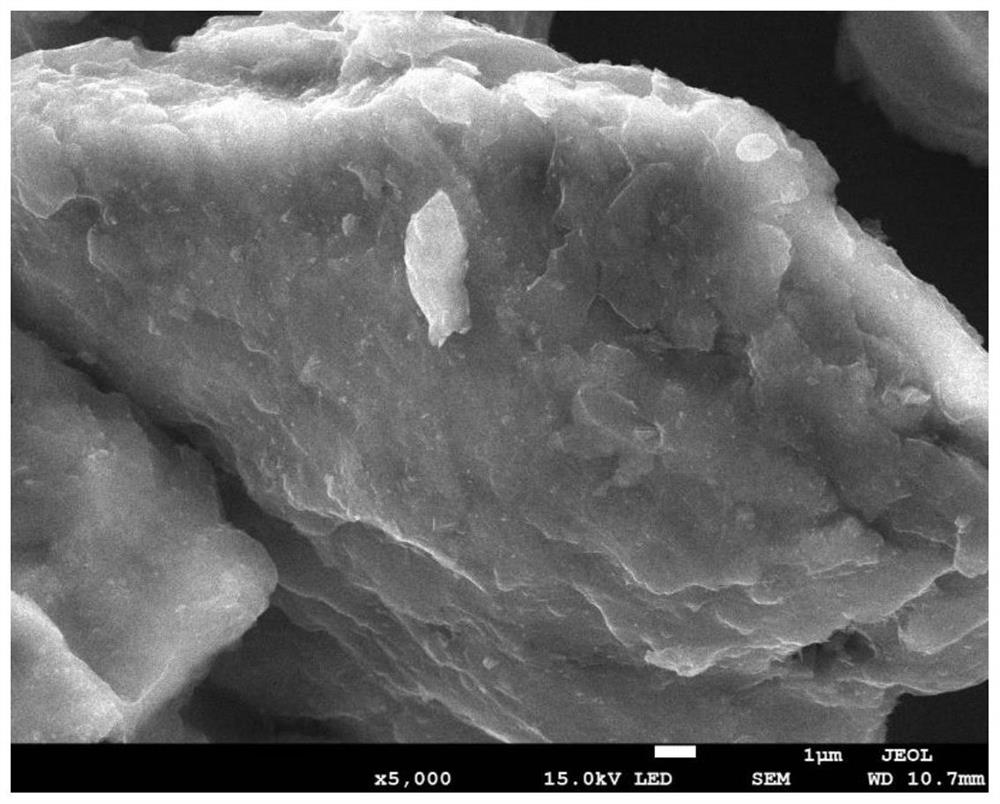

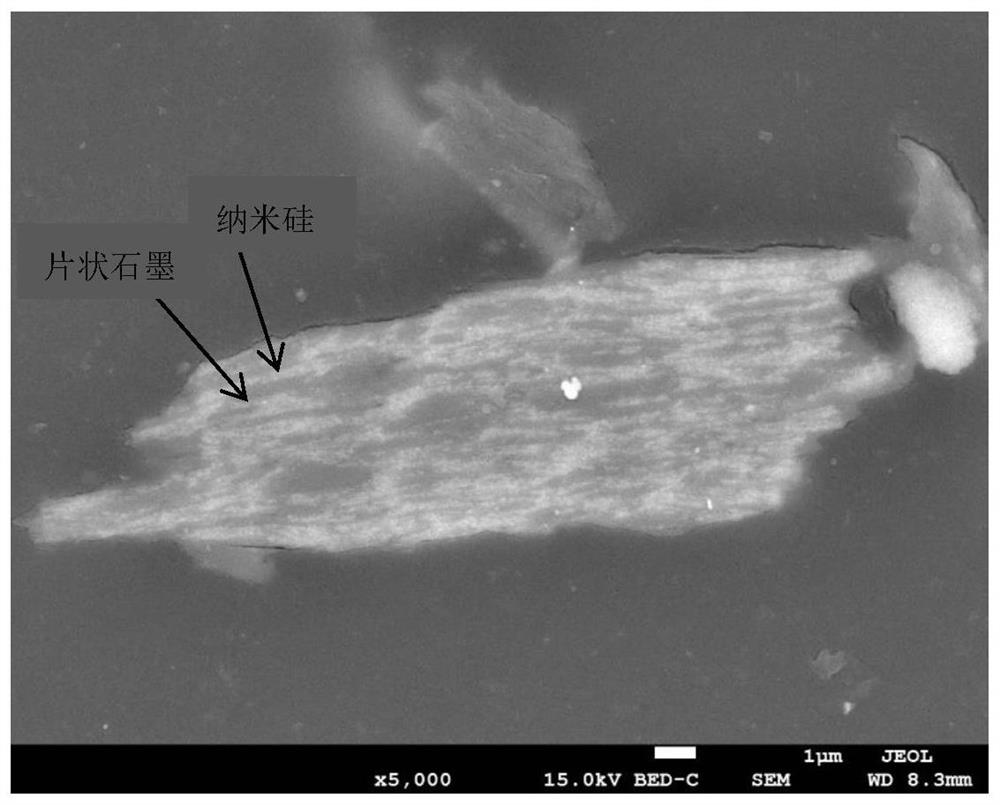

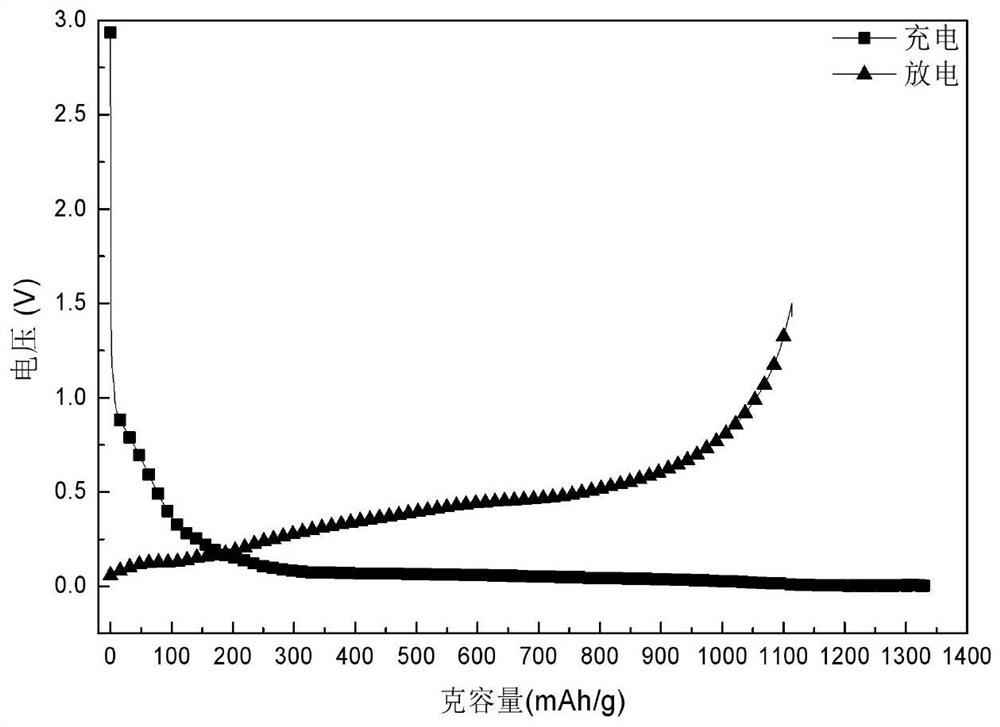

Silicon-carbon composite negative electrode material with high-density structure and preparation method of silicon-carbon composite negative electrode material

PendingCN114447294AGood electrochemical cycle performanceEliminate structural voidsNegative electrodesSecondary cellsCarbon coatingPolymer substrate

The invention provides a silicon-carbon composite negative electrode material with a high-density structure and a preparation method thereof.The silicon-carbon composite negative electrode material comprises a silicon / graphite composite inner core, the silicon / graphite composite inner core comprises multiple layers of flake graphite and nanometer silicon, the flake graphite is arranged in an oriented mode, and the nanometer silicon is located between the flake graphite to form a sandwich structure; gaps among particles in the silicon / graphite composite core are filled with a carbon material; and the silicon / graphite composite core is coated with a carbon layer. The preparation method comprises the following steps: dispersing nano silicon and flake graphite or a composition of flake graphite and other carbon materials in a solvent, carrying out ultrasonic treatment, adding a binder, and uniformly mixing; coating a polymer substrate with the obtained silicon / graphite slurry, and drying to obtain a lamellar material; performing hot pressing after stacking; roasting is performed; crushing and shaping; carrying out carbon coating treatment; depolymerizing and sieving; the material has high density and high strength, and solves the problems of poor circulation and limited increase of volume energy density when a silicon-carbon negative electrode is applied to a battery.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

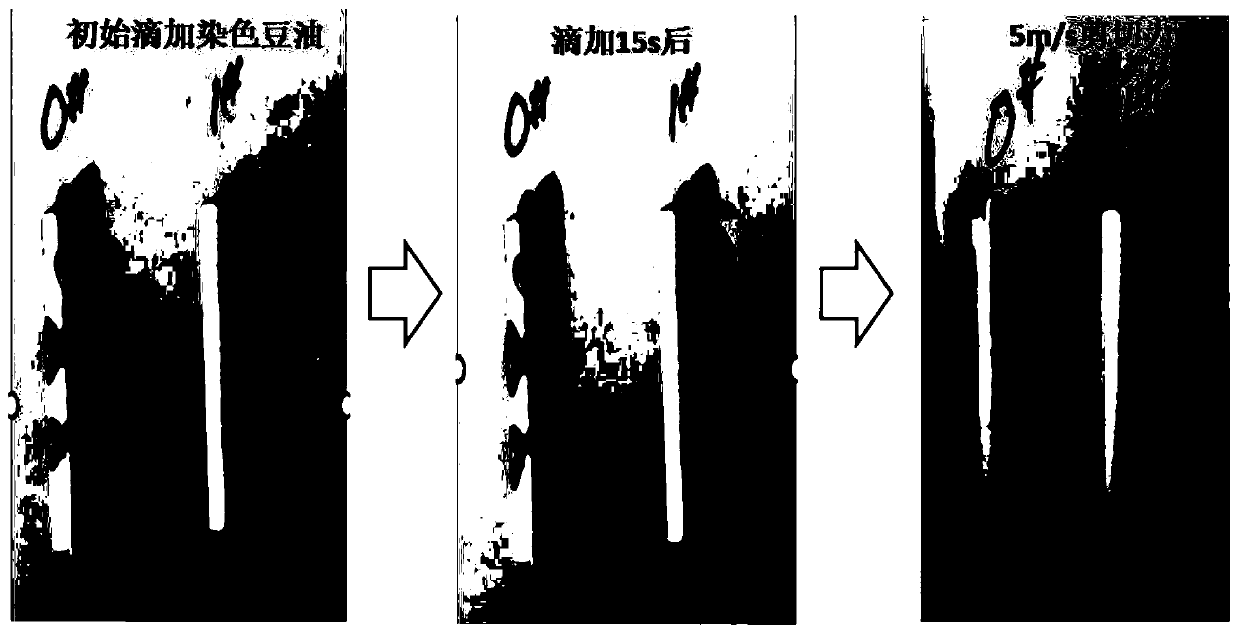

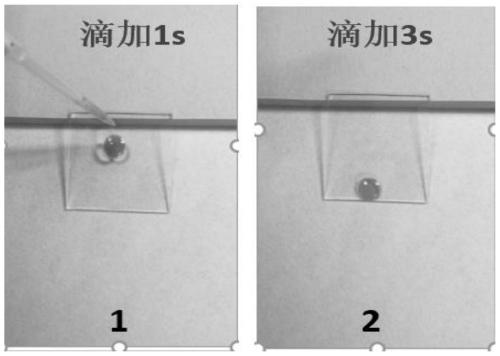

A kind of anti-oil, anti-fouling, self-cleaning fluorine-free coating and preparation method thereof

ActiveCN109609028BHigh bonding strengthHigh hardnessAntifouling/underwater paintsPaints with biocidesOil and greaseFan blade

The invention discloses an antifouling biomimetic coating with low adhesion of oil and fat and a preparation method of the antifouling biomimetic coating. Dolphin elastic skin is adopted as a basic research model of the coating, and the coating is obtained through crosslinking of polymer materials with a high elastic modulus and a low surface energy. Through control on the cross-linking density ofthe coating, change of low surface energy content and other parameter control, the adhesion resistance of the coating to various oil and low-surface-tension liquids is achieved. The coating has excellent oil adhesion resistance in both static and dynamic environments. The coating can be applied to multiple substrate surfaces, and can be applied to surfaces of various metals, ceramics, glass, various polymer materials and other materials, the adhesion between the coating and a substrate is high, and good transparency, flexibility, corrosion protection and other performance are achieved; and the coating is mainly applied to ventilation device blades, fume hood fan blade parts, smoke exhaust ventilator fan blade parts and other fan blade parts, and has a good application prospect and economic significance in reduction of surface oil stain and dust pollution, reduction of energy consumption, improvement of the work efficiency and reduction of energy consumption.

Owner:JILIN UNIV

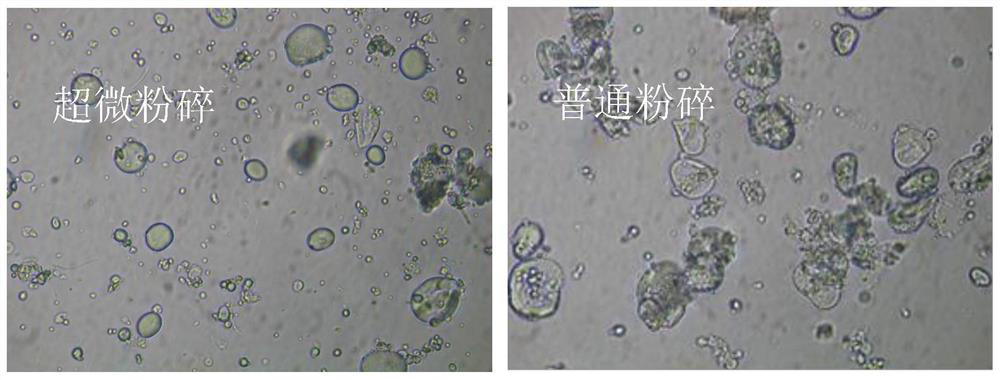

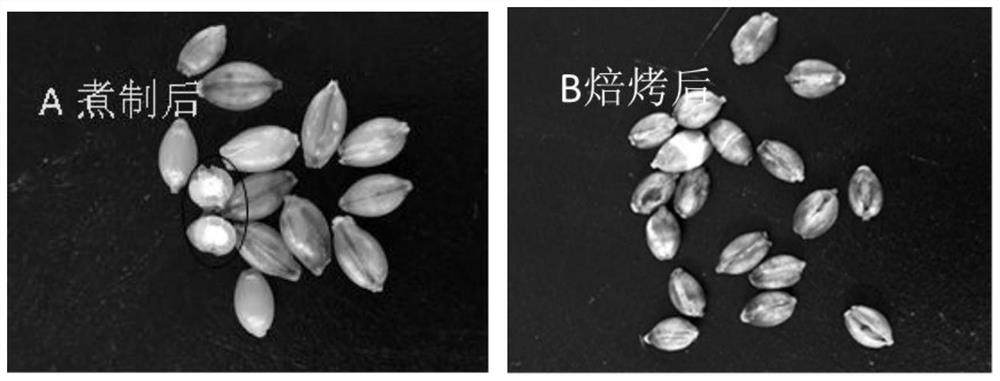

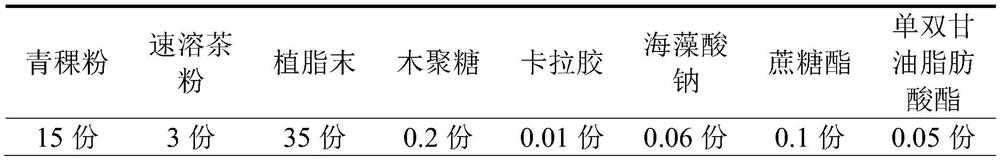

A kind of highland barley liquid milk tea and preparation method thereof

ActiveCN110447733BGood dispersionImprove adhesionMilk preparationPre-extraction tea treatmentBiotechnologyInstant tea

The invention discloses a highland barley liquid milk tea and a preparation method thereof. The method is as follows: (1) putting raw highland barley grains into boiling water and boiling for 20-40 minutes, then baking at 150-200° C., cooling, performing superfine grinding, and sieving to obtain highland barley powder; (2) pressing In terms of parts by mass, 10-20 parts of highland barley powder, 3 parts of instant tea powder, 35 parts of non-dairy creamer, 0.2 part of xylan, 0.07-0.35 part of thickener and 0.13-0.38 part of emulsifier are dissolved in 100 parts of water , high-pressure homogenization, cooling, packaging, and sterilization to obtain highland barley liquid milk tea. The invention adopts the superfine pulverization technology, can retain the nutritional components of the highland barley to the greatest extent, and improves the dispersibility and solubility of the highland barley powder. The curing method used in the present invention is a boiling+roasting method. The boiling can fully diffuse water into the highland barley grains, which can not only reduce the roasting time, but also make the highland barley grains roast more completely and release the aroma of the highland barley grains.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of composite conductive shielding materials

InactiveCN102373446BLess investmentLow running costLiquid/solution decomposition chemical coatingPolyesterChemical solution

The invention provides a preparation method of composite conductive shielding materials, which completely adopts a chemical deposition method for preparation. The method has the obvious advantages that the flow process is short, the cost is low, and the environment is protected. The method adopts the following technical scheme that the preparation method of the composite conductive shielding materials is characterized in that a copper layer and a silver layer are coated and plated on the surface of polyester or polyamide nonconductive materials by the chemical deposition method. The method has the process flow that the surface chemical pretreatment, the chemical copper plating, the water cleaning, the chemical silver plating and the color degradation prevention treatment are carried out on the surfaces of the polyester or polyamide nonconductive materials, the chemical pretreatment process is carried out in chemical solution containing 8 to 15ml / l of hydrochloric acid, 0.1 to 0.6g / l of palladium chloride and 10 to 16g / l of stannous chloride, the treatment time is 10 to 15min, and the treatment temperature is 20 to 35 DEG C.

Owner:山东中特防科技发展有限公司

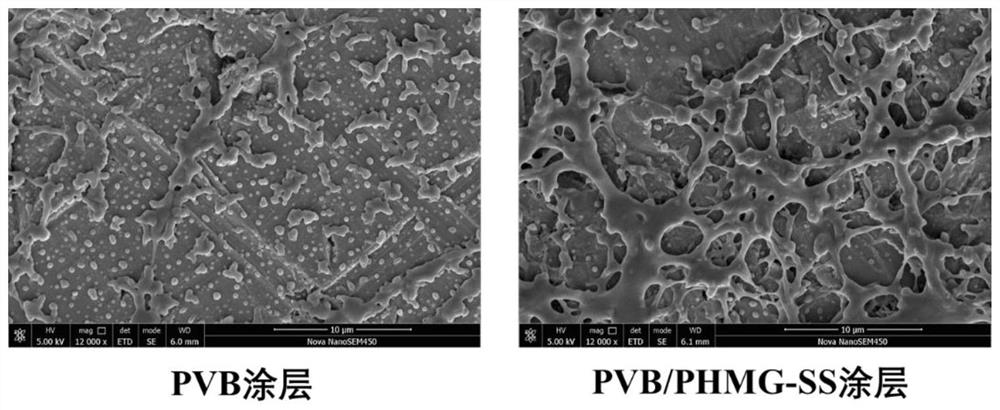

A kind of preparation method of in-situ toughened polypropylene alloy

InactiveCN104559205BImprove interface compatibilityImprove low temperature resistanceThermoplastic elastomerAlloy

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

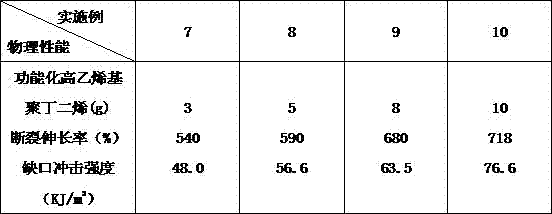

Soil conditioner as well as preparation method and application thereof

PendingCN114790393ARestoration of pasture vegetationReduce soil bulk densityOther chemical processesContaminated soil reclamationFertilizerChemistry

The invention provides a soil conditioner as well as a preparation method and application thereof, the preparation method comprises the following steps: (1) mixing fly ash, a calcium source, potassium hydroxide, an activating agent and water, and uniformly stirring to obtain raw slurry; and (2) carrying out hydrothermal reaction on the raw slurry obtained in the step (1) to obtain clinker slurry, and carrying out solid-liquid separation to obtain the soil conditioner. The soil conditioner is of a hollow porous structure; the specific surface area is 83.3-121.1 m < 2 > / g; and the porosity is 77.2 to 91.8 percent. According to the application, the soil conditioner is applied once every 1-5 years. The application amount each time is 5-500kg / mu; the fertilizer is applied to soil in a rotary tillage, ploughing, hole application or broadcast application mode, or is mixed with seeds and then sown into the soil. According to the preparation method of the soil conditioner, the beneficial element activation rate is increased, the product microstructure is improved, the soil conditioning function and effect are enhanced, the production cost is reduced, and continuous large-scale industrial production of the soil conditioner is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

A method for refining and purifying calcium formate

ActiveCN104447276BSimple production processIncrease productivityCarboxylic compound separation/purificationOrganic solventCalcium formate

The invention discloses a method for refining and purifying calcium formate. The method comprises the following steps: fully mixing a calcium formate solution with any concentration and a selected organic solvent at normal temperature and crystallizing; separating a separated-out calcium formate crystal by means of filtration; drying to obtain a high-purity calcium formate solid product. During production of calcium formate, the calcium formate product is always in a solution state; the solid product can be obtained only by evaporative crystallization; by adopting the method, the evaporative crystallization process can be saved; the calcium formate crystal can be obtained directly, so that the production process is simplified, the production efficiency is improved and the production energy consumption is reduced. The method can be used for producing food-grade and feed-grade high-purity calcium formate products and the like and also has the advantages of good product quality, simple production process, high production efficiency, low production energy consumption, easily-implemented continuous production and the like, so the method is a totally new calcium formate refining and purification technology.

Owner:YUNNAN CHEM RES INST

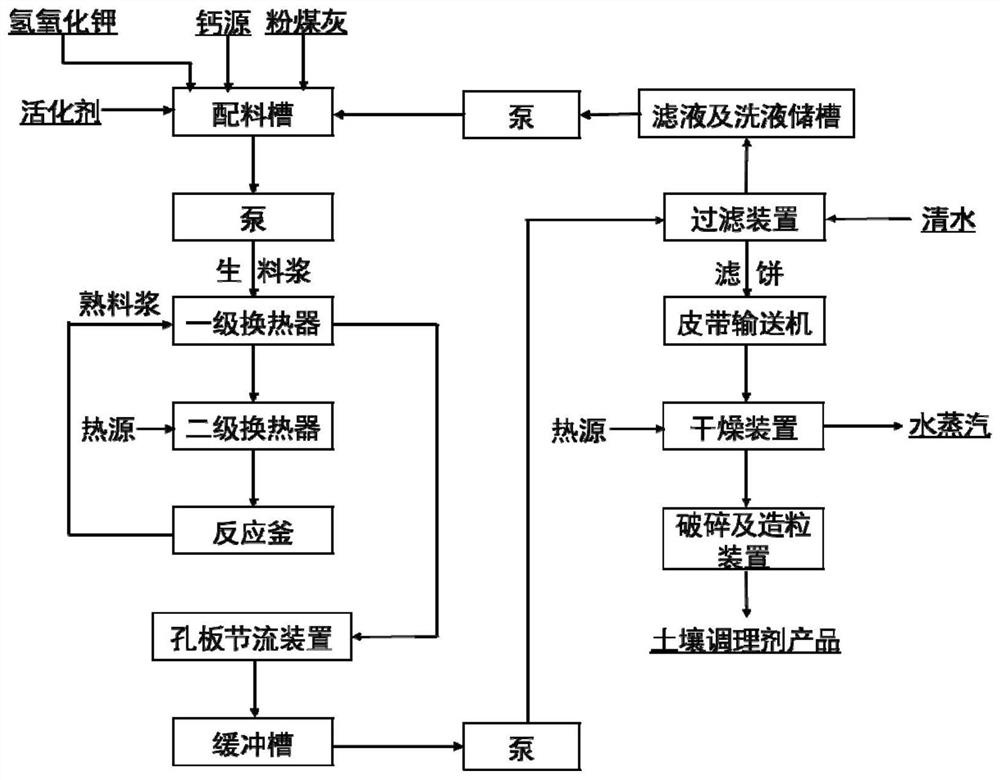

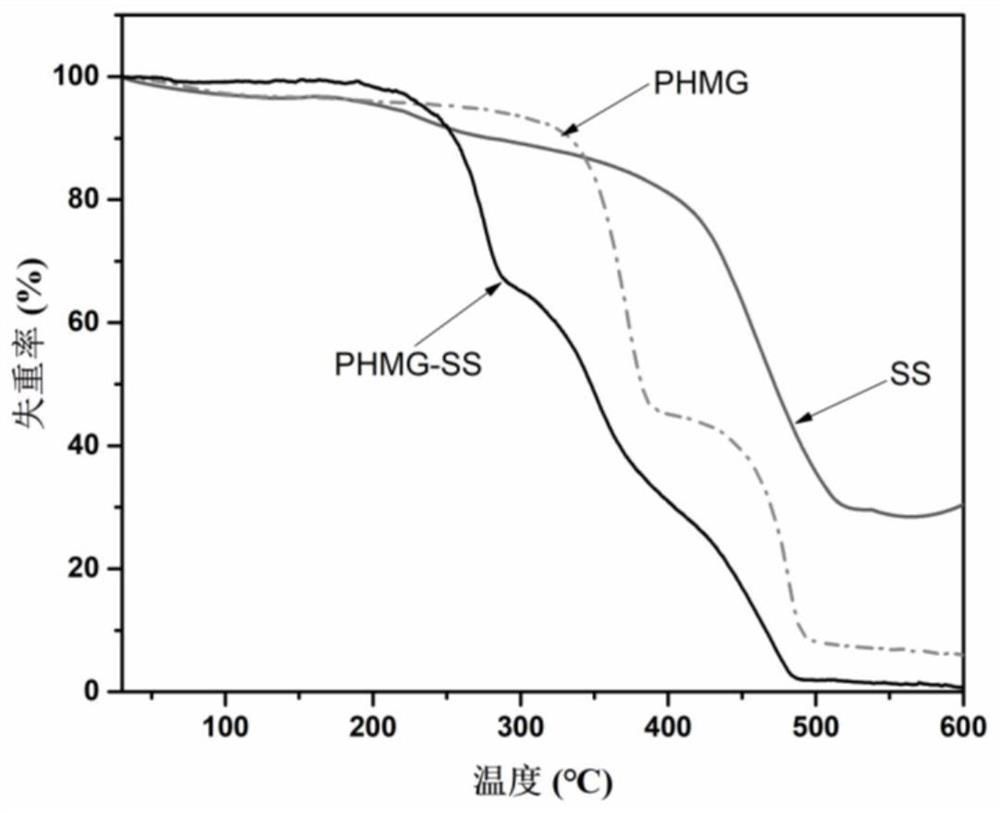

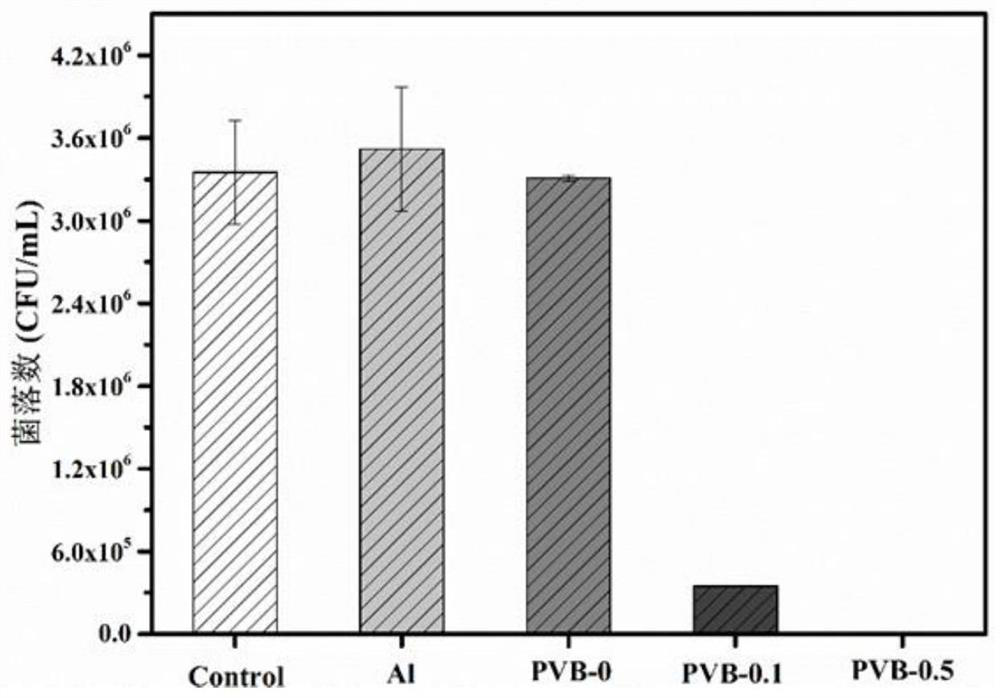

Antibacterial coating for inner wall of aviation fuel tank and preparation method thereof

ActiveCN112876917BNo pollution in the processSimple processAntifouling/underwater paintsPaints with biocidesAviationPolyvinyl alcohol

The invention discloses an antibacterial coating for the inner wall of an aviation fuel tank and a preparation method thereof. The antibacterial agent in the antibacterial coating of the present invention is a water-insoluble compound composed of polymer guanidine salt and fatty acid salt, and the compound antibacterial agent and the binder polyvinyl butyral have good compatibility in a certain solvent . The mixed solution of the composite antibacterial agent and polyvinyl butyral is coated on the aluminum sheet by dip coating method or spraying method, and an antibacterial coating is formed on the surface of the aluminum sheet after drying. The method is simple and easy to operate, and has no pollution to the environment. Easy to mass-produce continuously. The antibacterial coating endows the aluminum sheet with excellent antibacterial properties, and the antibacterial rate can reach 100% after being in contact with bacteria for 10 minutes. The dissolution of the antibacterial agent has high-efficiency, long-lasting, broad-spectrum and rapid antibacterial properties, which can effectively avoid the corrosion of the inner wall of the aviation fuel tank, the deterioration of the fuel quality, and the engine failure caused by microbial contamination.

Owner:SICHUAN UNIV

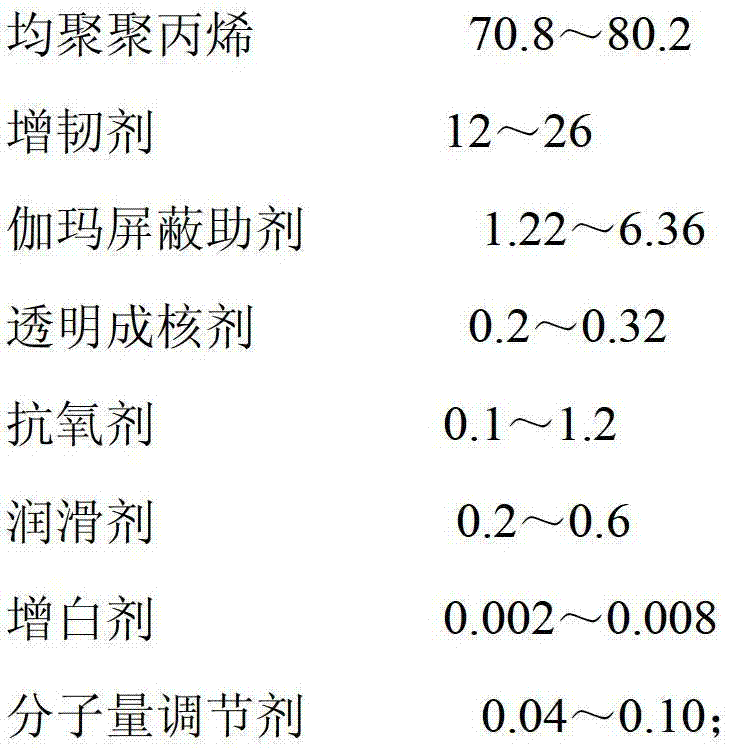

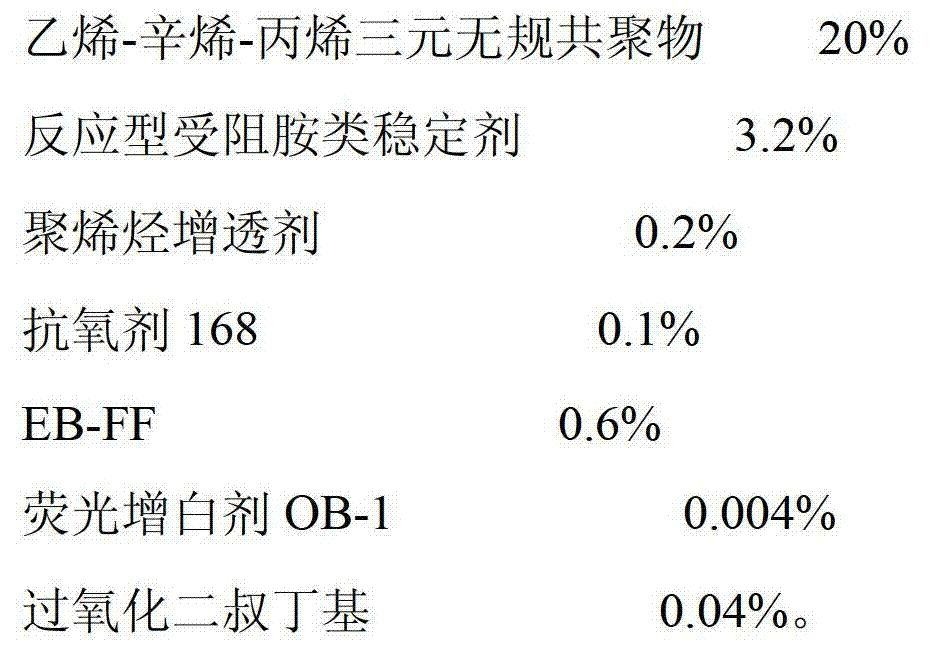

Medicinal low-temperature-resistant toughening anti-gamma ray impact-resistant transparent polypropylene material and preparation method thereof

Owner:苏州晋圣博高分子材料科技有限公司

Method for preparing high-strength cast nylon product

The invention provides a method for preparing a high-strength cast nylon product, which comprises the following steps of: mixing nylon particles with a certain amount of nano iron oxide magnetic powder, spinning by utilizing melt electrostatic spinning, directionally winding the fibers on a plate, and magnetizing in a high-intensity magnetic field environment to endow the fibers with certain magnetism; cutting the magnetized fibers into magnetized short fibers with a certain length; and uniformly dispersing the magnetized short fibers in a caprolactam solution added with a basic catalyst and a caprolactam solution added with an activating agent respectively to serve as a component A and a component B for reaction injection molding, fully mixing the two solutions A and B and injecting the mixed solution into a specially-designed mold through a reaction injection molding machine, and in a mold cavity, under the action of a magnetic field, heating a mold to the temperature lower than the melting point of nylon to cure caprolactam, and finally, obtaining a product. The fibers which are directionally arranged under the action of the magnetic field enables the mechanical property of the composite material in the stress direction to be greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

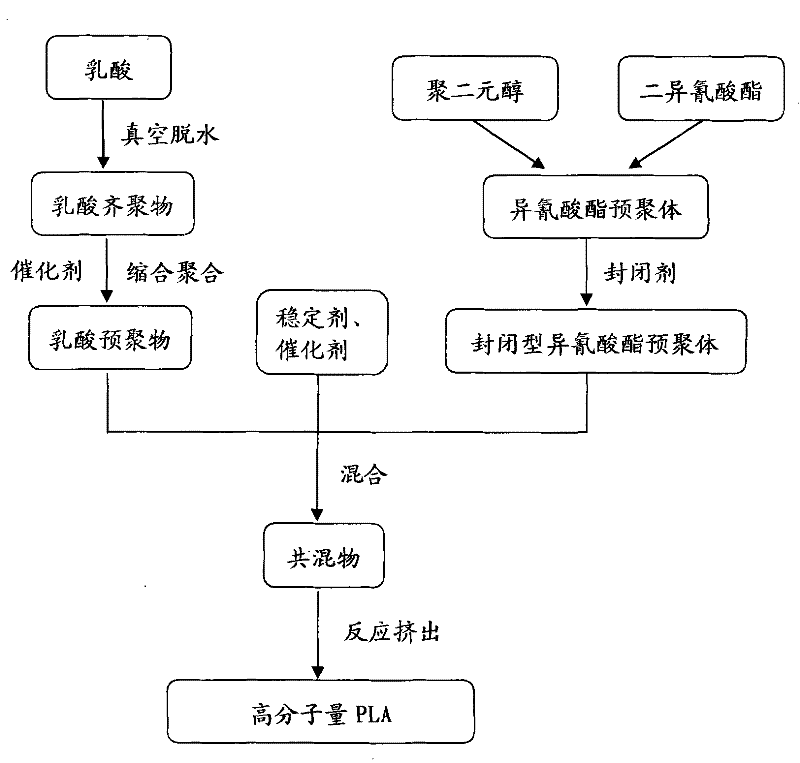

Preparation of high molecular weight high performance polylactic acid

The invention relates to a method for preparing poly lactic acid with high molecular weight. In the invention, bifunctional isocyanate, poly diol and isocyanate sealant are chosen to prepare an enclosed type isocyanate prepolymer and also used for the condensation polymerization reaction of a PLA prepolymer for extruding the chain extension, thereby realizing the preparation of the PLA with high molecular weight and high performance by one-step reaction. For the chain extension PLA of the enclosed type isocyanate prepolymer, the flexible polyether is introduced into the PLA, which obviously improves the toughness, the hydrolyzing resistance, the thermal stability and the endurance of products; moreover, the enclosed type isocyanate prepolymer chain extender can also overcome the problems that the small molecule isocyanate chain extender fears of water while being stored and can not be pre-mixed with materials, and the volatilization of the small molecule isocyanate chain extender harms the health of a tester and the storage time of the small molecule isocyanate chain extender is short; by utilizing the enclosed type isocyanate prepolymer reaction to extrude the chain extension PLA prepolymer, the method has the advantages of simple equipment, short reaction time, easily controlled reaction condition and easy realization of large-scale and continuous production.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

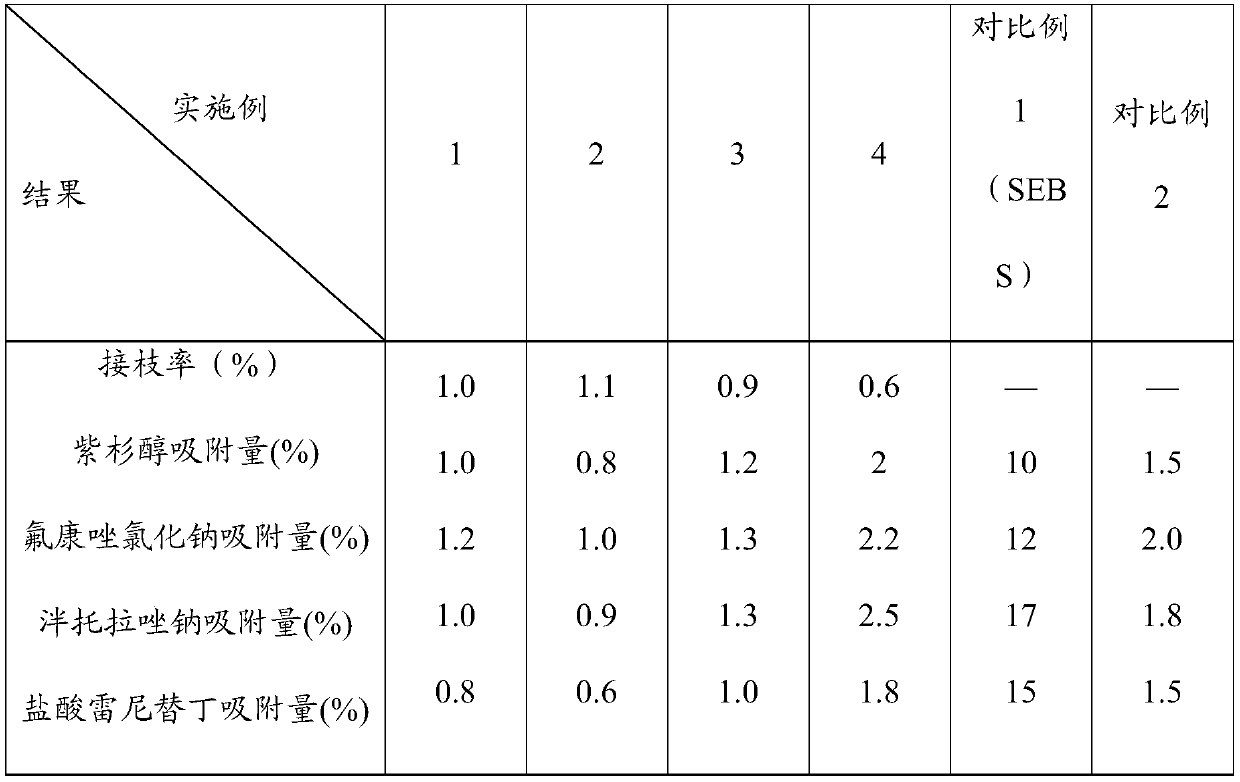

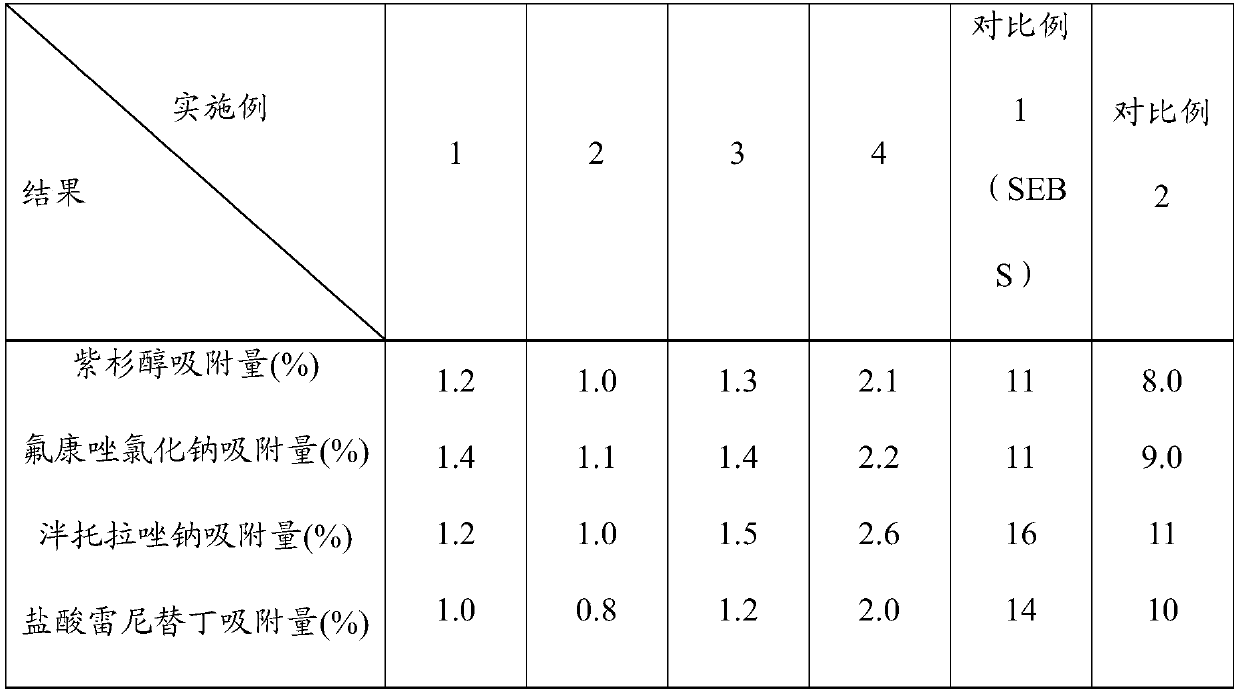

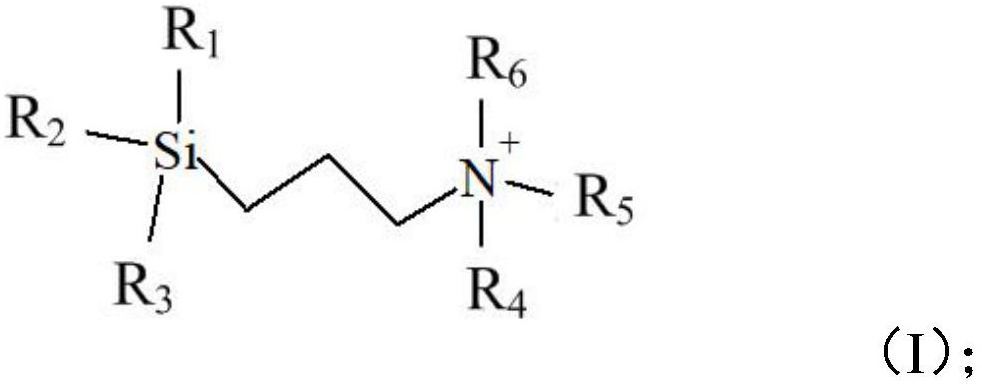

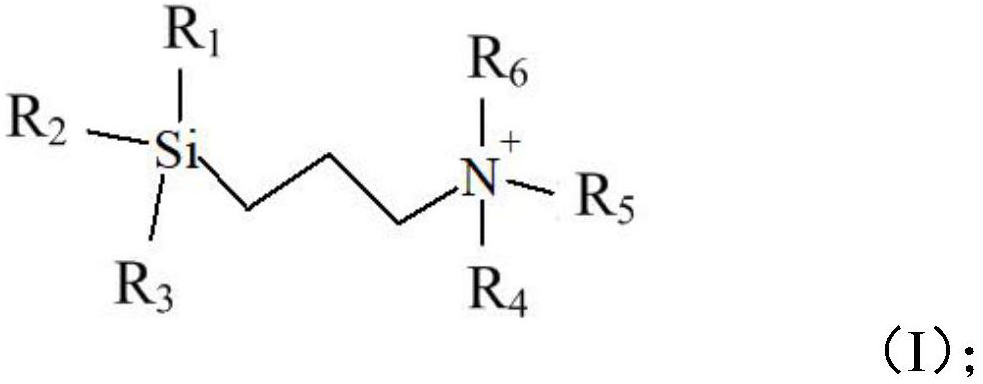

A kind of low drug adsorption TPS and its preparation method and application

The present invention provides that the low drug adsorption TPS provided by the present invention is obtained by melting and grafting after mixing pre-irradiated TPS with one of the organic peroxide initiators, TPS and reactive vinyl fluorosilicone oil. In the twin-screw extruder, reactive vinyl fluorosilicone oil is grafted on the TPS molecular chain by melt reaction extrusion to reduce the adsorption of TPS devices to drugs and improve drug efficacy during input or storage. It has the advantages of not easy to precipitate, long-lasting anti-drug adsorption performance, etc. The low-drug adsorption TPS prepared by the invention can be applied to both fat-soluble and water-soluble drugs, and can be used in the fields of medical devices such as drug infusion and storage devices. The product has low drug adsorption and long-lasting and stable performance. In addition, the low-drug adsorption TPS has a simple preparation method, has no pollution to the environment, and is easy to realize large-scale continuous production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Environment-friendly bamboo-plastic automobile instrument and manufacturing method thereof

Owner:SHANGHAI HAN MOLDING SHAPE CO LTD

A kind of surface anticoagulant modification method of polymer material

ActiveCN111635549BImprove stain resistanceImprove stabilityHeparin coatingsAlginic acid coatingsPlasma activationLow temperature plasma

The invention relates to the technical field of medical polymer materials and medical devices, in particular to a method for modifying the anticoagulant surface of polymer materials. The invention provides a method for modifying the anticoagulant surface of a polymer material, comprising the following steps: A) subjecting the polymer material to low-temperature plasma activation treatment; B) placing the activated polymer material in a After 0.5 to 10 minutes in the organic solution of the complex, take it out and dry it to obtain a polymer material covered with a charge complex; the charge complex is prepared from raw materials including sodium alginate and organosilicon quaternary ammonium salt; C) the The polymer material coated with the charge complex is placed in the aqueous solution of sodium heparin for 0.5-10 minutes, taken out, and heated at 40-80° C. to obtain the polymer material containing an anticoagulant coating. The anticoagulant coating obtained by the anticoagulant surface modification method of the polymer material provided by the invention is not easy to fall off, and has better anticoagulant effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Antibacterial modifier and preparation method thereof, antibacterial modified thermoplastic elastomer and preparation method thereof

The invention provides an antibacterial modifier and a preparation method thereof, an antibacterial modified thermoplastic elastomer and a preparation method thereof. The antibacterial modifier provided by the invention is a polyguanidine-fatty acid salt complex formed by combining polyguanidine salt and fatty acid salt. The antibacterial modifier provided by the present invention has good compatibility with the thermoplastic elastomer matrix, is uniformly dispersed, is not easy to precipitate, has good antibacterial property and long-lasting antibacterial performance, and can significantly improve the antibacterial efficiency; in addition, the antibacterial modifier is resistant to high temperature and can avoid Side reactions such as pyrolysis occur in the process of preparing the antibacterial material, thereby avoiding the problem of antibacterial inactivation; moreover, the antibacterial agent has no toxic and side effects, and can be better used in the field of medical devices. In addition, the preparation method is simple and easy, has no pollution to the environment, and is easy to realize large-scale continuous production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Modified polypropylene and preparation method thereof

The invention provides a preparation method of modified polypropylene. The preparation method comprises the following steps: mixing polypropylene resin, pre-irradiated polypropylene, a double-bond-containing reactive hindered amine radiation-resistant agent, a lubricant and a hydrophobic polyelectrolyte antibacterial / antiviral compound, and carrying out a melting reaction to obtain the modified polypropylene. The invention also provides the modified polypropylene. The modified polypropylene prepared in the invention has the characteristics of high fluidity, irradiation resistance, antibiosis and antivirus, has a high melt index, and can be used for preparing polypropylene special materials for melt blowing.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Composite pipe blank casting device and continuous casting method

The invention relates to a composite metal material casting device and a continuous casting method, in particular to a composite pipe blank casting device and a continuous casting method. The casting device is structurally characterized in that an external control valve is arranged at an outlet end of an external heat-insulation furnace, an internal control valve is arranged at an outlet end of an internal heat-insulation furnace, the internal heat-insulation furnace is communicated with a crystallizer by the internal control valve, a core head is arranged at the front end of the crystallizer, a pouring pipe is arranged on the outlet end of the external heat-insulation furnace, the core head is positioned in the pouring pipe, and the crystallizer and the external heat-insulation furnace are respectively communicated with the pouring pipe; the pouring pipe is internally provided with a traction pipe, the inner end of the traction pipe is plugged with the core head, and the outer end ofthe traction pipe is connected with a tractor; and an electromagnetism generator is arranged outside the pouring pipe. The continuous casting method includes the steps of melting and heat insulation of alloy blanks, electromagnetic continuous casting of a composite pipe blank, cutting of the pipe blank, and quality check of the composite pipe blank. In the invention, the technique process and theequipment are both simpler, large-scale continuous production can be easily realized, and the production cost of the composite pipe blanks can be greatly lowered.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP +1

Method for preparing radiation and aging resistant polypropylene alloys

The invention provides a method for preparing radiation and aging resistant polypropylene alloys. Reactive hindered amine stabilizers are grafted on a polypropylene molecular chain by a reactive extrusion method to improve the aging resistance of materials after the alloys are subjected to radiation sterilization. The radiation and aging resistant polypropylene alloys prepared by a reactive grafting method have the advantages of uniform dispersion of the stabilizers, difficult precipitation, durable aging resistance and the like. The radiation and aging resistant polypropylene alloys have simple preparation method, have no pollution to the environment, and are easy to realize mass continuous production. The radiation and aging resistant polypropylene alloys prepared by the method can be applied in fields such as medical infusion instruments, food packaging, medicament packaging and the like; and after a radiation sterilization method is adopted for sterilization and within one year ofstorage period, the elongation at break of products is reduced and is less than 50 percent, the tensile strength is reduced and is less than 2MPa, and the yellowness index is increased and is less than 1. Therefore, the radiation and aging resistant polypropylenes have strong radiation and aging resistance.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com