Soil conditioner as well as preparation method and application thereof

A technology of soil conditioner and activator, which is applied in the field of solid waste reuse, and can solve problems such as imperfect process, failure to consider heating and cooling of the reaction system, heat recovery and recycling product microscopic morphology regulation process technical problems, etc. Achieve the effect of improving soil air permeability, developing internal pore structure and reducing soil bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

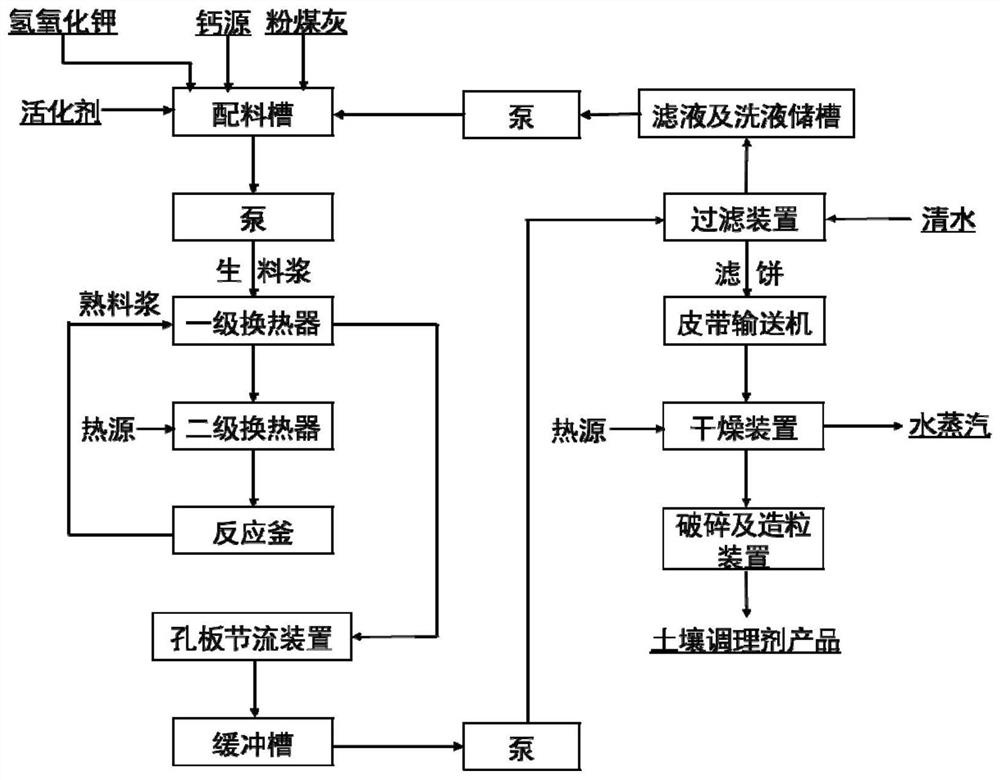

[0067] The present embodiment provides a soil conditioner and a preparation method thereof, such as figure 1 As shown, the preparation method comprises the following steps:

[0068](1) Use fly ash from a power plant in Hulunbuir, Inner Mongolia, use calcium oxide as calcium source, and use manganese chloride and zinc chloride as activators; first add circulating solution (filtrate and washing liquid) to the batching tank, and add hydroxide Adjust the concentration of potassium to 0.5mol / L to prepare lye solution; add calcium oxide and fly ash to the lye solution according to the ratio of solid phase and liquid phase as 1kg: 13L, and ensure that silicon element and calcium oxide in fly ash are The molar ratio of calcium element is 1:0.9, and the activator is added according to 0.05% of the total mass of fly ash and calcium oxide, wherein the mass ratio of manganese chloride and zinc chloride is 3:1, and it is prepared after stirring evenly. raw pulp;

[0069] (2) use a plunge...

Embodiment 2

[0072] The present embodiment provides a soil conditioner and a preparation method thereof, such as figure 1 As shown, the preparation method comprises the following steps:

[0073] (1) Use fly ash from a power plant in Hulunbuir, Inner Mongolia, take calcium oxide as calcium source and manganese chloride as activator; first add circulating solution (filtrate and washing liquid) to the batching tank, and add potassium hydroxide to adjust its concentration Calcium oxide and fly ash are added to the lye solution according to the ratio of solid phase and liquid phase as 1kg: 15L, and the silicon element in fly ash and calcium element in calcium oxide are ensured. The molar ratio is 1:0.7, and the activator is added according to 1% of the total mass of fly ash and calcium oxide, and the raw slurry is prepared after stirring evenly;

[0074] (2) The raw material slurry obtained in step (1) is sent into the primary heat exchanger with a diaphragm pump, and is exchanged with the cli...

Embodiment 3

[0077] The present embodiment provides a soil conditioner and a preparation method thereof, such as figure 1 As shown, the preparation method comprises the following steps:

[0078] (1) Use fly ash from a power plant in Xilinhot, Inner Mongolia, use calcium hydroxide as calcium source, and use manganese nitrate and ferrous chloride as activators; first add circulating solution (filtrate and washing liquid) to the batching tank, and add hydrogen The concentration of potassium oxide is adjusted to 0.01mol / L to prepare lye; calcium hydroxide and fly ash are added to the lye solution according to the ratio of solid phase and liquid phase as 1kg: 20L, and it is ensured that the silicon element in the fly ash and the The molar ratio of calcium element in calcium hydroxide is 1:1, and the activator is added according to 2% of the total mass of fly ash and calcium hydroxide, wherein the mass ratio of manganese nitrate and ferrous chloride is 1:1, and stirring is uniform After the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com