A kind of highland barley liquid milk tea and preparation method thereof

A liquid and milk tea technology, which is applied in milk preparations, dairy products, tea extraction, etc., can solve the problems of high difficulty in industrial production, high production cost, and difficult guarantee of product quality, so as to improve storage stability, avoid production problems, Produce easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

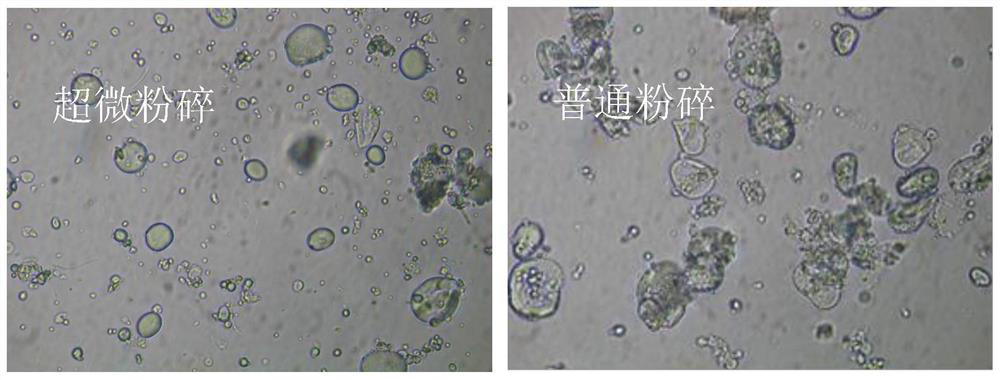

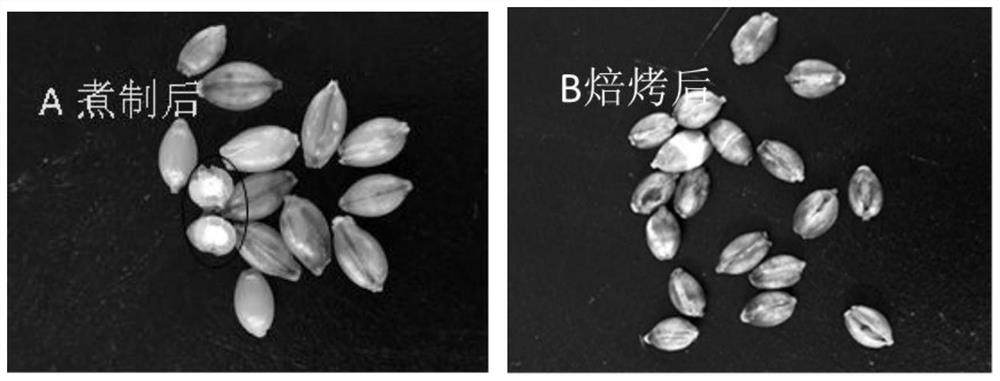

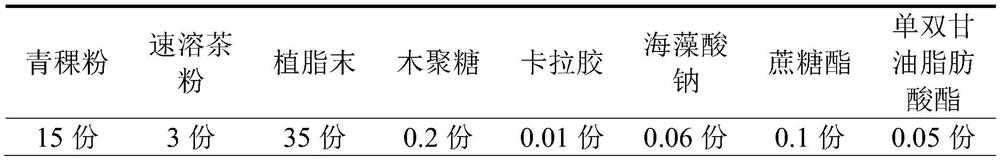

[0033] Put the raw barley grains in boiling water and cook for 20 minutes, so that the water completely enters the barley grains. Then spread the cooked barley evenly in a baking dish, put it in the oven, 180 ° C, bake for 3 minutes and then remove and let cool. The cool barley grains are super-finely crushed, and after sifting, 200 mesh barley powder is obtained. The resulting barley powder and instant tea powder, vegetable fat powder, xylan, thickener (carrageenan, sodium alginate) and emulsifier (sucrose esters, mono and diglyceride fatty acid esters) in proportion to the proportion of dissolved in water (100 parts, 70 ° C) (according to the amount shown in Table 1), and then by high pressure homogeneous emulsification, cooling, packaging, sterilization, i.e., to obtain the milk tea, wherein the high pressure homogenization pressure is 100MPa, the homogenization frequency is 5 times. The barley grain blasting degree is high, the barley aroma is strong, the consistency of milk t...

Embodiment 2

[0037] Put the raw barley grains in boiling water and cook for 20 minutes, so that the water completely enters the barley grains. Then spread the cooked barley evenly in a baking dish, put it in the oven, 180 ° C, bake for 3 minutes and then remove and let cool. The cool barley grains are super-finely crushed, and after sieving, 300 mesh barley powder is obtained. The resulting barley powder and instant tea powder, vegetable fat powder, xylan, thickener (carrageenan, sodium alginate) and emulsifier (sucrose esters, mono and diglyceride fatty acid esters) in proportion to the proportion of dissolved in water (100 parts, 70 ° C) (according to the amount shown in Table 2), and then by high pressure homogeneous emulsification, cooling, packaging, sterilization, i.e., to obtain the milk tea, wherein the high pressure homogenization pressure is 100MPa, the average number of times is 5 times. The degree of blasting of barley grains is high, the aroma of barley is strong, the consistency ...

Embodiment 3

[0041] Put the raw barley grains in boiling water and cook for 30 minutes, so that the water completely enters the barley grains. Then spread the cooked barley grains evenly in a baking sheet, put them in the oven at 200 ° C, bake for 1 minute and then remove and let cool. The cool barley grains are super-finely crushed, and after sieving, 300 mesh barley powder is obtained. The resulting barley powder and instant tea powder, vegetable fat powder, xylan, thickener (carrageenan, sodium alginate) and emulsifier (sucrose esters, mono and double glyceride fatty acid esters) in proportion to the proportion of dissolved in water (100 parts, 70 ° C) (according to the amount shown in Table 3), and then by high pressure homogeneous emulsification, cooling, packaging, sterilization, that is, to obtain the milk tea, wherein the high pressure homogenization pressure is 100MPa, the average number of times is 5 times. The barley grain blasting degree is high, the barley aroma is strong, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com