Silicon-carbon composite negative electrode material with high-density structure and preparation method of silicon-carbon composite negative electrode material

A silicon-carbon composite and negative electrode material technology, applied in negative electrodes, structural parts, battery electrodes, etc., can solve the problem that the cycle performance and compaction density are not comparable to graphite negative electrodes, and the capacity advantages of silicon-based materials are difficult to reflect, material capacity and pressure. It can solve problems such as the reduction of solid density, and achieve the effect of solving the limited increase in volumetric energy density, good electrochemical cycle performance, and eliminating structural voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

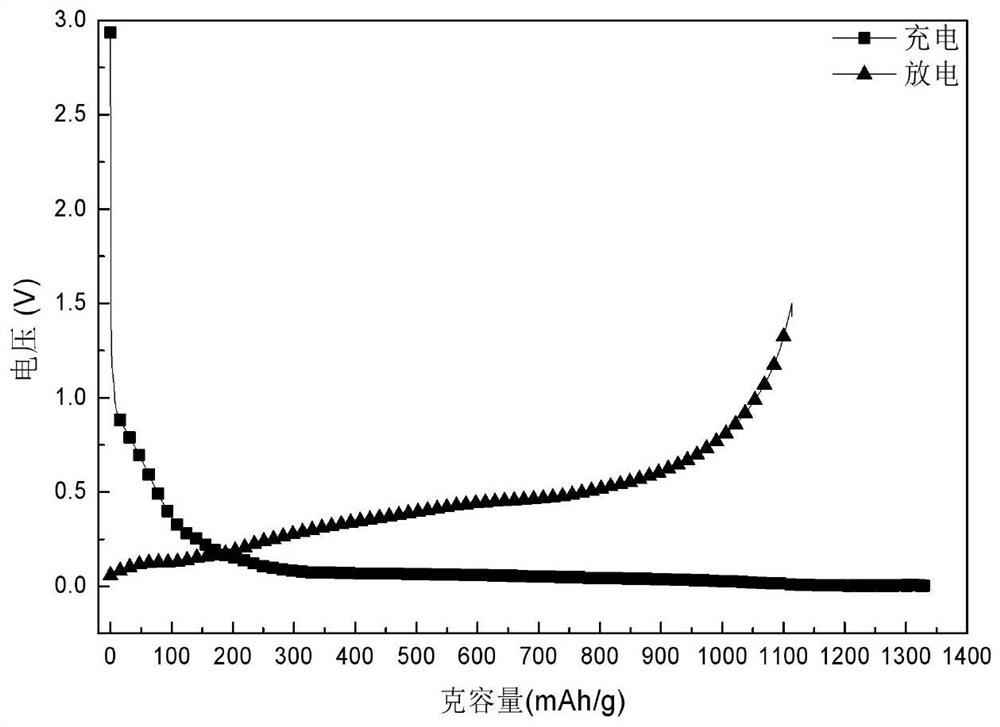

Embodiment 1

[0051] A method for preparing a silicon-carbon composite negative electrode material with a highly dense structure, comprising the following steps:

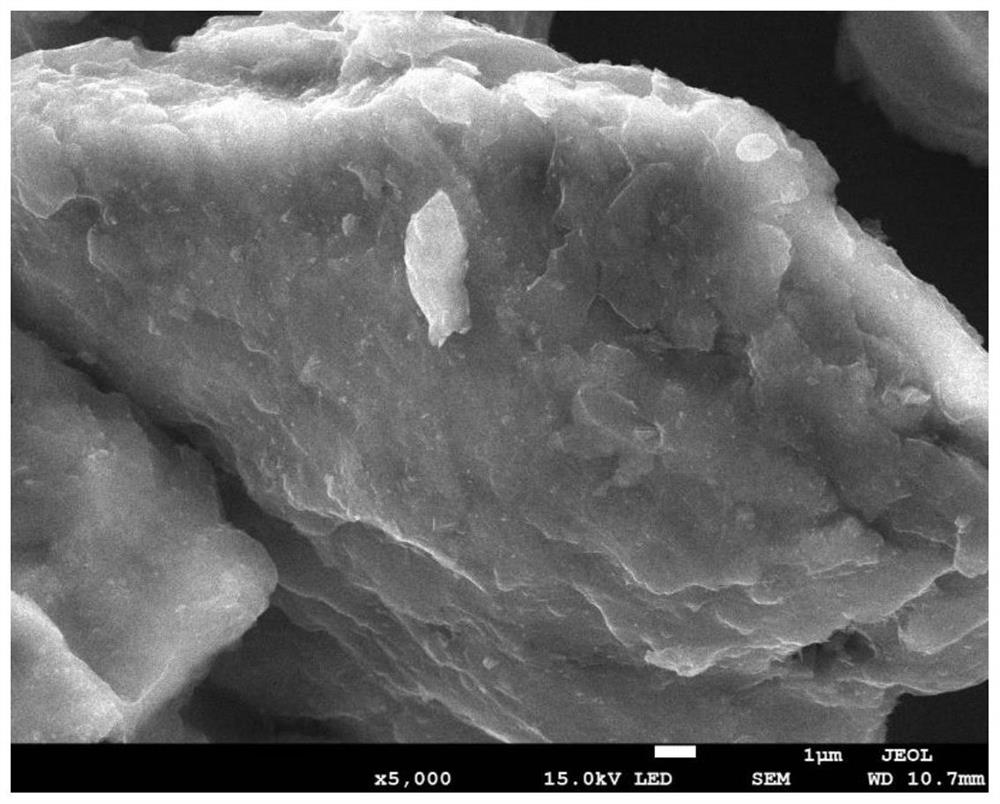

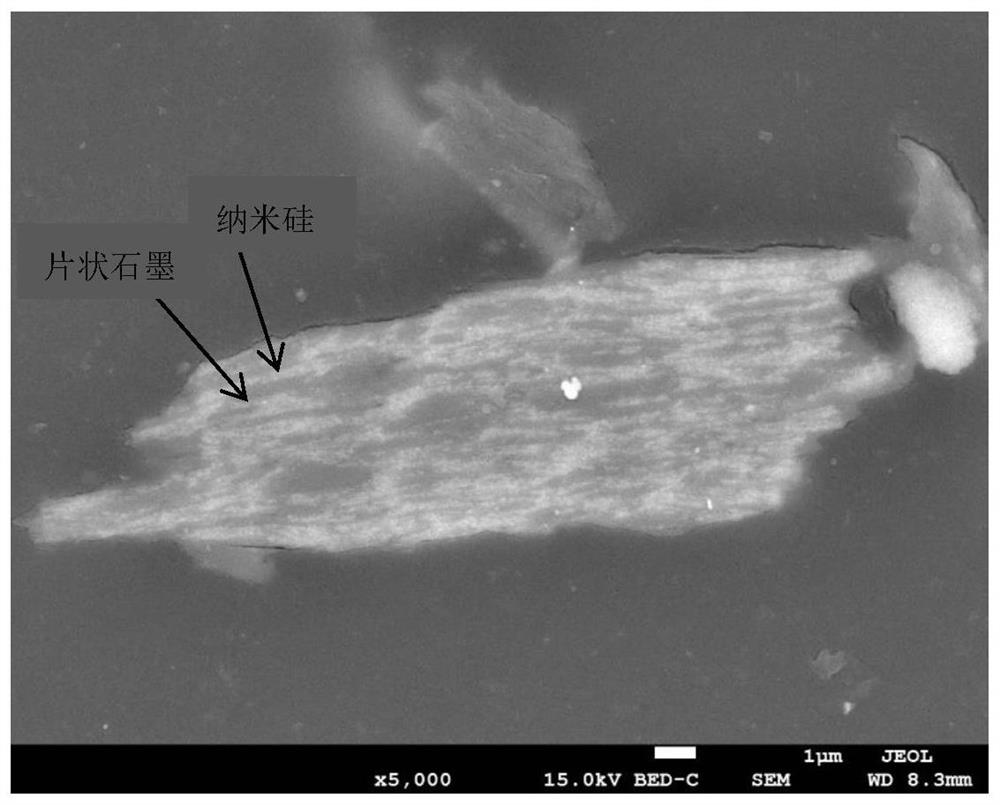

[0052] (1) Get 100g of silicon powder with a median particle size of 80nm and 120g of flaky graphite with a median particle size of 3 μm and disperse them in 1kg of ethanol, ultrasonically disperse for 30min, add 22g of epoxy resin and 2g of organically modified polysiloxane, Mix 2h to obtain silicon / graphite slurry;

[0053] (2) The above-mentioned silicon / graphite slurry is coated on a polyethylene film with a thickness of 0.05mm by casting coating equipment, and dried at 100°C to obtain a polyethylene film and a silicon / graphite coating with a thickness of 3mm. sheet material;

[0054] (3) The above sheet material is rolled by a pair of rollers (hot roller press), and the temperature of the roll processing is 120° C. to obtain a rolled sheet material, the thickness of which is 1mm;

[0055] (4) slice the above-mentioned roll...

Embodiment 2

[0062] A method for preparing a silicon-carbon composite negative electrode material with a highly dense structure, comprising the following steps:

[0063] (1) Disperse 200g of silicon powder with a median particle size of 100nm and 400g of flake graphite with a median particle size of 8 μm in 4kg of isopropanol, ultrasonically disperse for 30min, add 30g of stearic acid and 2.5g of polyacrylate solution, Mix 2h to obtain silicon / graphite slurry;

[0064] (2) The above-mentioned silicon / graphite slurry is coated on a polyvinyl chloride film by casting coating equipment, and dried at 110° C. to obtain a sheet material with a thickness of 5 mm of a polyvinyl chloride film and a silicon / graphite coating ; Wherein, the thickness of polyvinyl chloride film is 0.08mm;

[0065] (3) The above-mentioned sheet material is carried out rolling processing by a common pair of rollers to obtain a rolled sheet material, and the thickness of the rolled sheet material is 0.9mm;

[0066] (4) ...

Embodiment 3

[0072] A method for preparing a silicon-carbon composite negative electrode material with a highly dense structure, comprising the following steps:

[0073] (1) Disperse 150 g of silicon powder with a median particle size of 80 nm and 750 g of flake graphite with a median particle size of 5 μm in 3 kg of ethanol, ultrasonically disperse for 30 min, add 35 g of citric acid, and mix for 2 h to obtain a silicon / graphite slurry;

[0074] (2) The above-mentioned silicon / graphite slurry is coated on a polyethylene film by casting coating equipment, and dried at 90° C. to obtain a sheet material with a polyethylene film and a silicon / graphite coating with a thickness of 3 mm; wherein , the thickness of the polyester film is 0.025mm;

[0075] (3) The above sheet material is rolled by a pair of rollers (hot roller press), and the temperature of the roll processing is 110° C. to obtain a rolled sheet material. The thickness of the rolled sheet material is 0.5mm ;

[0076] (4) After sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com