Modified polypropylene and preparation method thereof

A polypropylene and polypropylene resin technology, applied in the field of modified polypropylene and its preparation, can solve the problems of reducing medical material security, organic peroxide explosion, affecting mechanical bacteria/virus filtration performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] In view of the problems of strong taste of additives, easy explosion and lack of antibacterial / antiviral functions in the preparation of ultra-high melt fluidity polypropylene in the prior art, this application provides a preparation method of modified polypropylene, which is obtained by introducing pre-irradiated polypropylene Propylene, double bond-containing reactive hindered amine radiation-resistant agent, lubricant and hydrophobic polyelectrolyte antibacterial / antiviral compound, so that the obtained modified polypropylene has a higher melt index, radiation resistance and antibacterial / antibacterial Antiviral. Specifically, the embodiment of the present invention discloses a preparation method of modified polypropylene, comprising:

[0020] The modified polypropylene is obtained by mixing polypropylene resin, pre-irradiated polypropylene, double bond-containing reactive hindered amine radiation resistance agent, lubricant and hydrophobic polyelectrolyte antibacter...

Embodiment 1

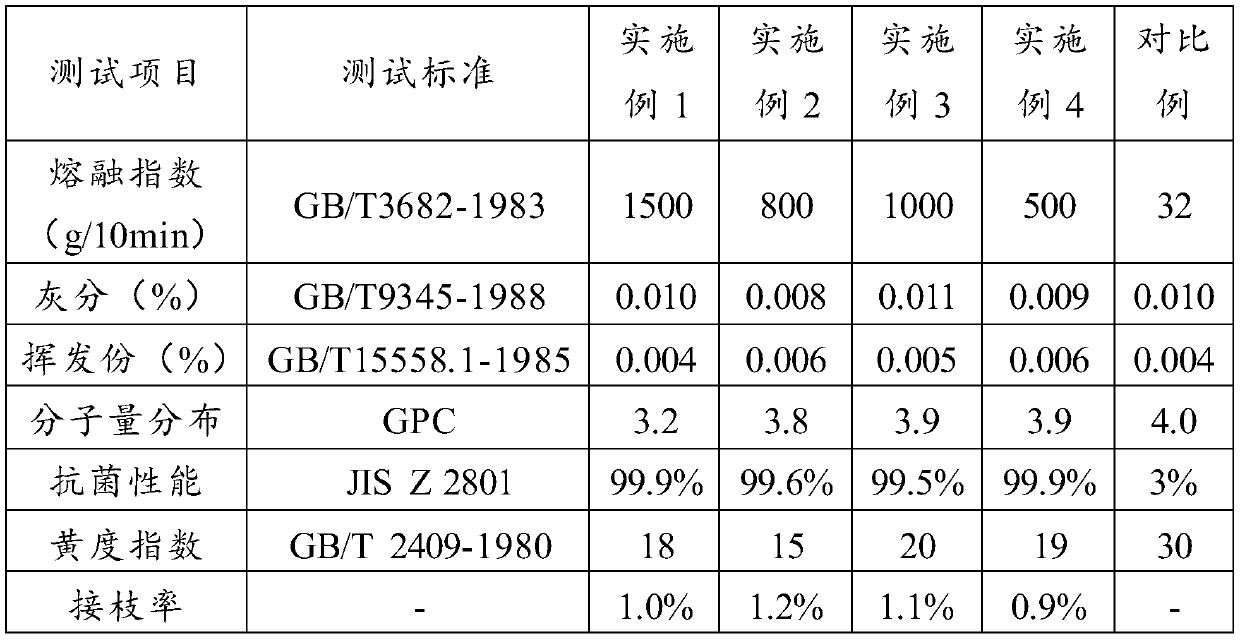

[0033] 1000g of polypropylene resin Z30S (melt index 30g / 10min (230°C, 2.16kg), Dalian Xitai Petrochemical Co., Ltd.), 600g of the above-mentioned polypropylene resin was irradiated by an electron accelerator at 200kGy, 4g of 4-acrylamide-2, 2,6,6-tetramethylpiperidine, 50g polyhexamethylene biguanide hydrochloride-sodium stearate antibacterial / antiviral compound, 2g ethylene bis stearamide are mixed in high mixer, then Put the obtained mixture into a twin-screw extruder for melt degradation and reactive extrusion grafting. The extrusion temperature is 250°C, the screw speed is 150rpm, and the residence time of the mixture is 0.9min. Stranding, cooling, pelletizing, and drying, The modified high-fluidity polypropylene was obtained, and the physical properties of the product are shown in Table 1.

[0034] Preparation method of polyhexamethylene biguanide hydrochloride-sodium stearate antibacterial / antiviral compound: respectively configure 1.5%wt / v polyhexamethylene biguanide h...

Embodiment 2

[0036] 1000g of polypropylene resin T30S (melt index 3.0g / 10min (230°C, 2.16kg), Daqing Petrochemical), 400g of the above-mentioned polypropylene resin was irradiated by an electron accelerator at 100kGy, 3g of 4-acrylamide-2,2,6, 6-Tetramethylpiperidine, 50g heparin sodium-benzalkonium chloride antibacterial / antiviral complex, 3g ethylene bisstearamide are mixed in a high mixer, and then the resulting mixture is added to a twin-screw extruder Carry out melt degradation and reactive extrusion grafting, the extrusion temperature is 220°C, the screw speed is 150rpm, the residence time of the mixture is 1.0min, the strands are drawn, cooled, pelletized, and dried to obtain modified high-fluidity polypropylene. As shown in Table 1.

[0037] Preparation method of heparin sodium-benzalkonium chloride antibacterial / antiviral complex: respectively configure the aqueous solution of heparin sodium and benzalkonium chloride of 1.5%wt / v, mix the two at room temperature to form a water-ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com