Method for preparing high-strength cast nylon product

A casting nylon, high-strength technology, applied in the field of polymer material molding, can solve the problems of destroying fiber orientation, inability to melt and process reinforcements, etc., and achieve improved modulus and impact resistance, good recyclability, equipment less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Utilize a kind of method for preparing high-strength cast nylon product of the present invention, prepare dumbbell-shaped tensile sample product, comprise following specific steps:

[0029] 1) Prepare an appropriate amount of commercial nano-ferric oxide powder, and put it into a vibrating sieve equipped with a 10,000-mesh screen. After fully sieving, keep the undersize for use; the oversize can be collected and passed through grinding Recycling after machine grinding;

[0030] 2) Add 9.6 kg of fully dried nylon 6 granules and 0.4 kg of nano iron ferric oxide powder sieved in the previous step into a plastic mixer, and mix well.

[0031] 3) Put the particles mixed uniformly in the previous step into the melt electrospinning machine fed by the screw, set the spinning voltage to 30KV, the receiving distance to 110mm, and the barrel temperature to 300°C for spinning to obtain ferric oxide mixed with Powdered Nylon 6 fine fibers.

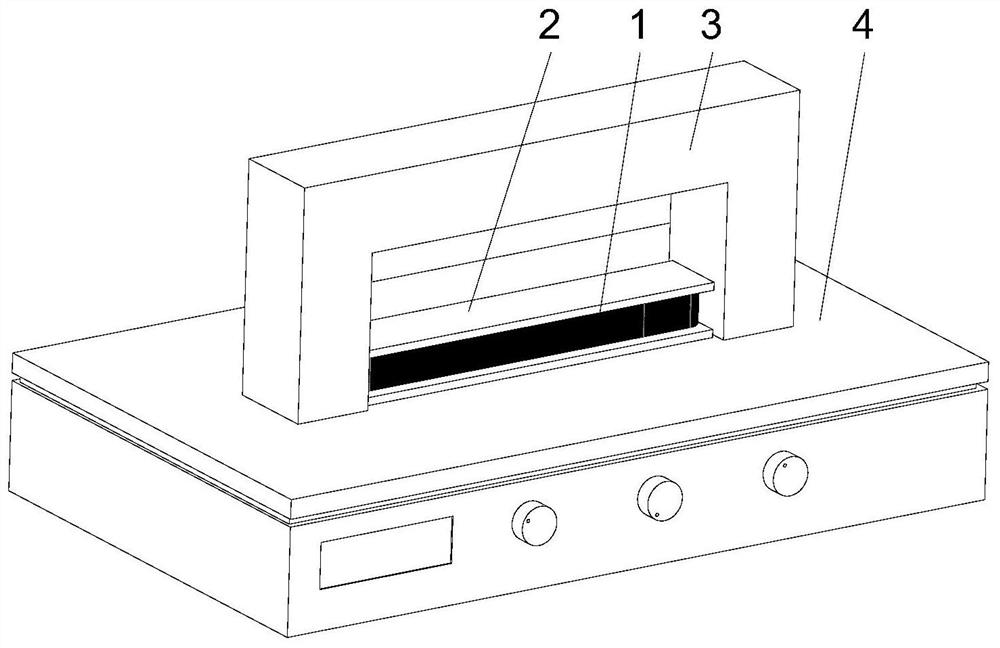

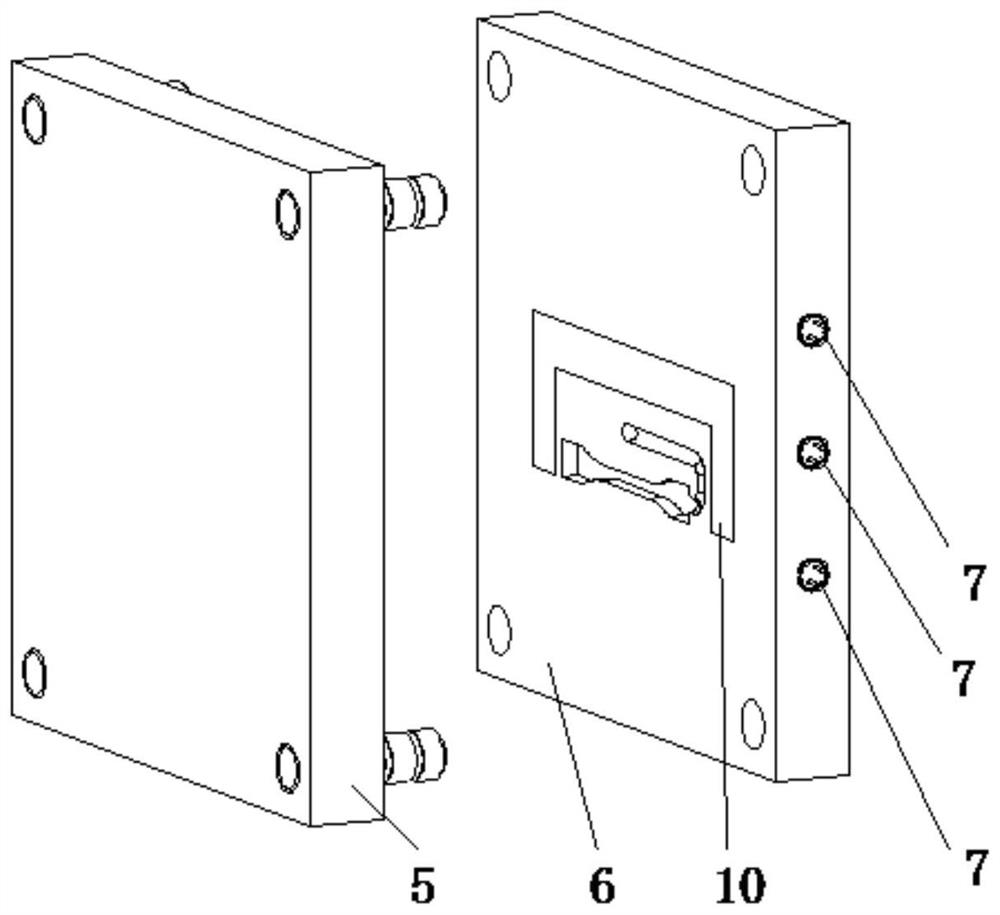

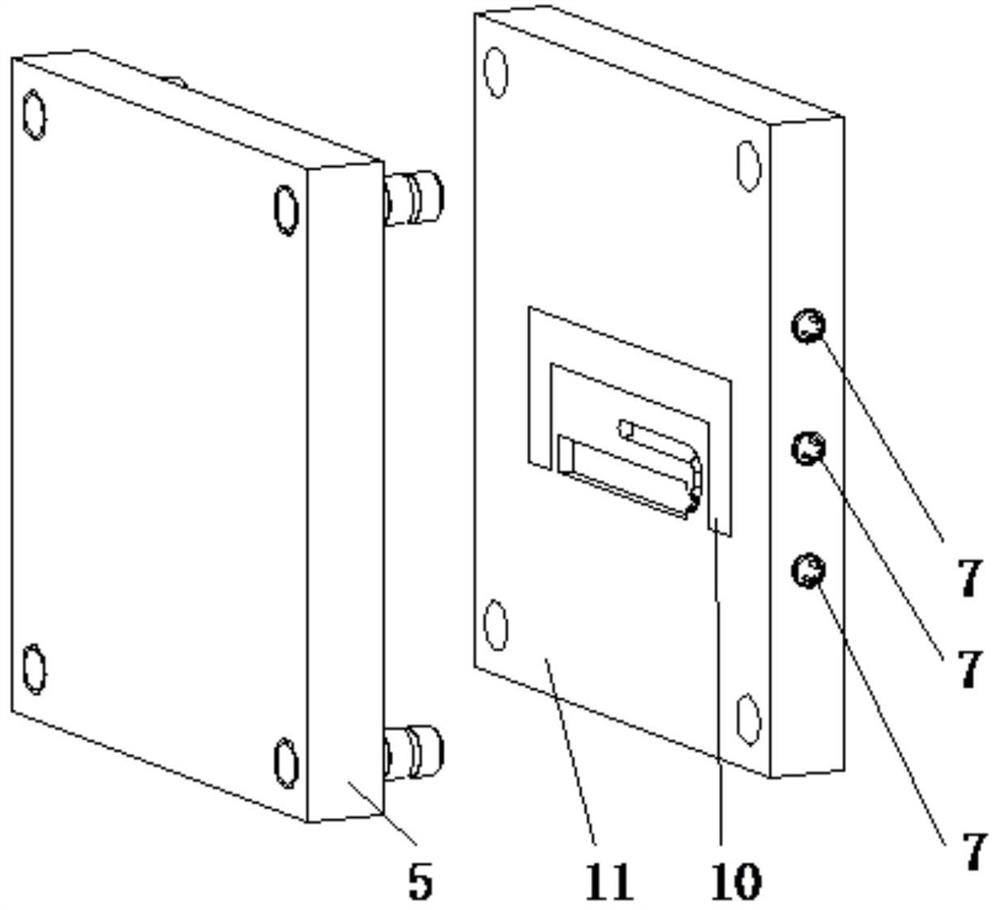

[0032] 4) if figure 1 As shown, the fib...

Embodiment 2

[0039] The difference from Example 1 is that this example uses a method for preparing high-strength cast nylon products of the present invention to prepare elongated impact sample products, including the following specific steps:

[0040] 1) Prepare an appropriate amount of commercial nano-ferric oxide powder, and put it into a vibrating sieve equipped with a 10,000-mesh screen. After fully sieving, keep the undersize for use; the oversize can be collected and passed through grinding Recycling after machine grinding;

[0041] 2) Add 8Kg of fully dried nylon 6 granules and 2kg of nano iron ferric oxide powder sieved in the previous step into a plastic mixer, and mix well.

[0042] 3) Put the particles mixed uniformly in the previous step into the melt electrospinning machine fed by the screw, set the spinning voltage to 30KV, the receiving distance to 110mm, and the barrel temperature to 300°C for spinning to obtain ferric oxide mixed with Powdered Nylon 6 fine fibers.

[004...

Embodiment 3

[0049] The difference from Example 1 is that this example uses a method for preparing high-strength cast nylon products of the present invention to prepare cylindrical compression sample products, including the following specific steps:

[0050] 1) Prepare an appropriate amount of commercial nano-ferric oxide powder, and put it into a vibrating sieve equipped with a 10,000-mesh screen. After fully sieving, keep the undersize for use; the oversize can be collected and passed through grinding Recycling after machine grinding;

[0051] 2) Add 9Kg of fully dried nylon 6 granules and 1Kg of nano iron ferric oxide powder sieved in the previous step into a plastic mixer, and mix well.

[0052] 3) Put the particles mixed uniformly in the previous step into the melt electrospinning machine fed by the screw, set the spinning voltage to 30KV, the receiving distance to 110mm, and the barrel temperature to 300°C for spinning to obtain ferric oxide mixed with Powdered Nylon 6 fine fibers. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com