Antibacterial coating for inner wall of aviation fuel tank and preparation method thereof

An antibacterial coating and fuel tank technology, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of coating antibacterial performance decline, antibacterial agent dissolution, cytotoxicity, etc., and achieve easy The effect of control, low cost and mild preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

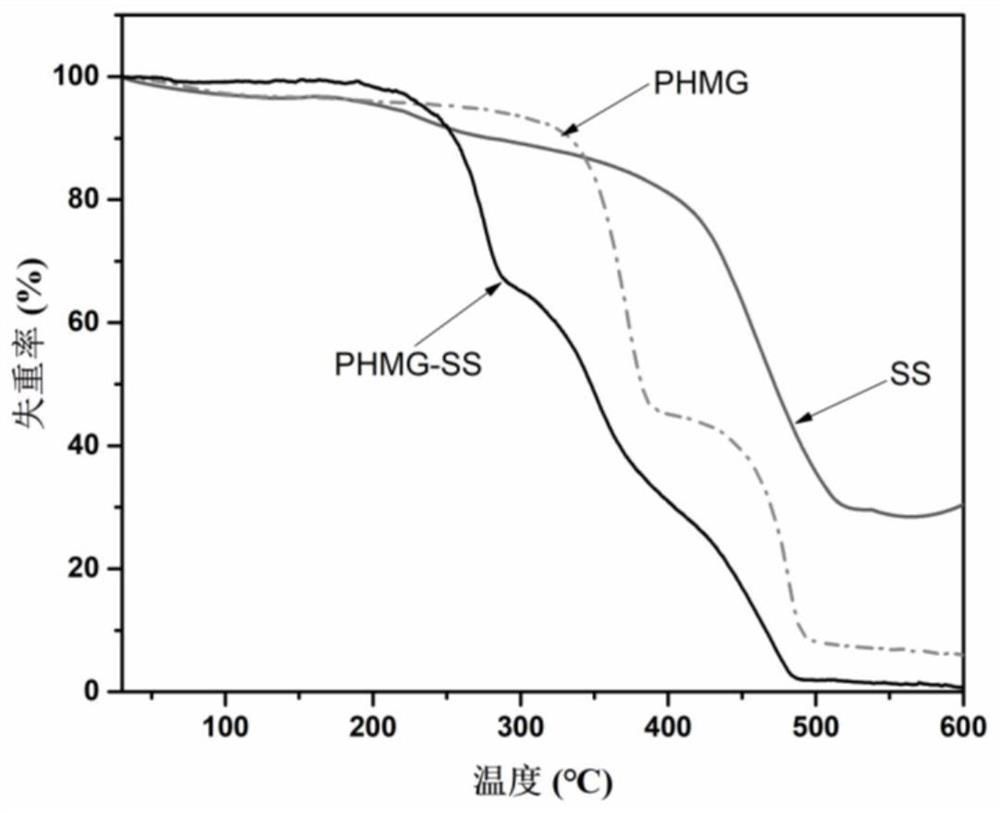

[0023] Prepare an aqueous solution of sodium stearate (SS) with a mass fraction of 5%, heat the SS solution to 70 °C to completely dissolve it, and slowly add the PHMB solution dropwise. The composite antibacterial agent PHMB-SS was obtained by thermal insulation polymerization for 3.5 h and then directly filtered, which was washed three times with hot water and dried at 60 °C under vacuum.

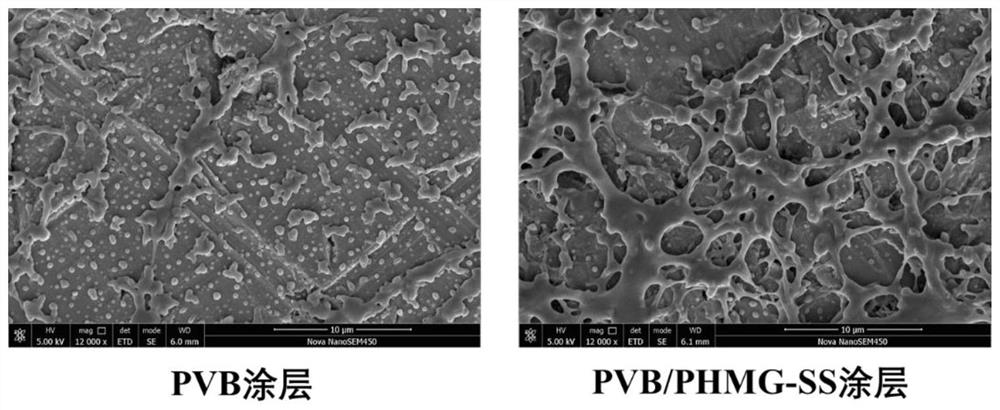

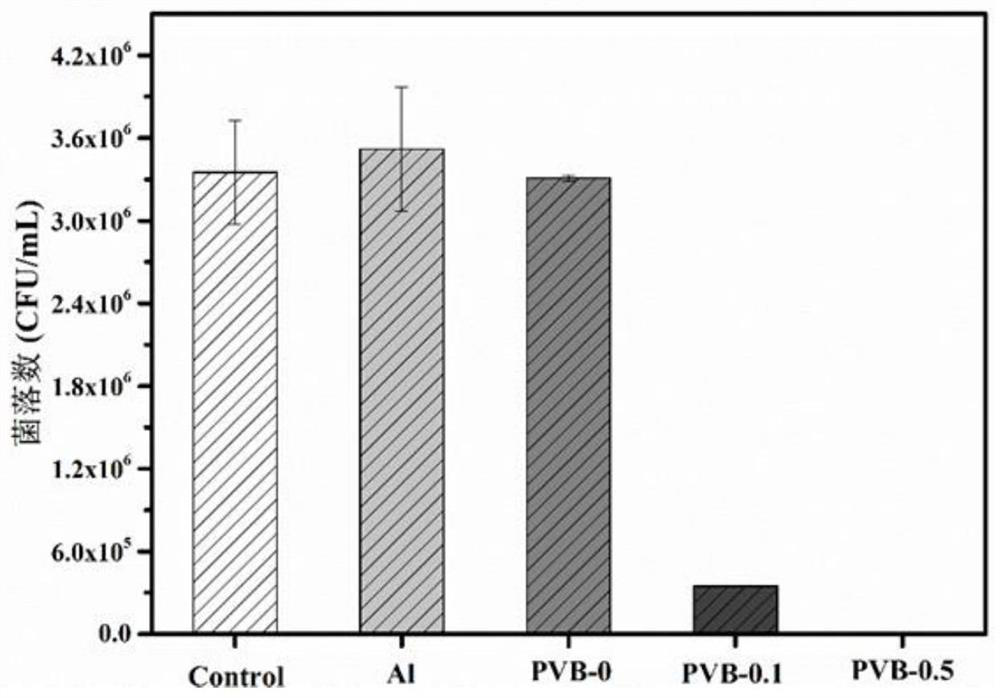

[0024]The mass fraction of 1 % polyvinyl butyral (PVB) and the mass fraction of 0.1 % PHMB-SS were added to the absolute ethanol solution, and the two were mixed to prepare a mixed solution of PVB and PHMB-SS. After the aluminum sheet was polished with 1000-grit sandpaper, ultrasonically cleaned with acetone, absolute ethanol and distilled water for ten minutes in turn, and dried. The dried aluminum sheet is repeatedly immersed in the above mixed solution for 3 times, so that the surface of the aluminum sheet is evenly covered with an antibacterial coating, and then dried to obtain an ant...

Embodiment 2

[0026] Prepare a 10% sodium stearate (SS) aqueous solution, heat the SS solution to 90 °C to dissolve it completely, slowly add the PHMG solution dropwise, and control the molar ratio of SS acid group to PHMG guanidine group at 1.0:1.0, After 2 h of polymerization, the composite antibacterial agent PHMG-SS was obtained by direct filtration, which was washed three times with hot water and dried under vacuum at 60 °C;

[0027] The mass fraction of 5% polyvinyl butyral (PVB) and the mass fraction of 0.5% PHMG-SS were added to the absolute ethanol solution, and the two were mixed to prepare a mixed solution of PVB and PHMG-SS. After the aluminum sheet was polished with 1000-grit sandpaper, ultrasonically cleaned with acetone, absolute ethanol and distilled water for ten minutes in turn, and dried. The dried aluminum sheet is immersed in the above mixed solution once to make the surface evenly covered with an antibacterial coating, taken out and then dried to obtain an antibacteria...

Embodiment 3

[0029] Prepare an aqueous solution of sodium palmitate (SP) with a mass fraction of 15%, heat the SP solution to 60 °C to completely dissolve it, slowly add the PHMG solution dropwise, and control the molar ratio of SP acid group to PHMG guanidine group at 1.0:2.0, keep the temperature After 2 h of polymerization, it was directly filtered to obtain the composite antibacterial agent PHMG-SP, which was washed with hot water for three times and dried under vacuum at 60 °C;

[0030] The mass fraction of 10 % polyvinyl butyral (PVB) and the mass fraction of 1 % PHMG-SP were added to the absolute ethanol solution, and the two were mixed to prepare a mixed solution of PVB and PHMG-SP. After the aluminum sheet was polished with 1000-grit sandpaper, ultrasonically cleaned with acetone, absolute ethanol and distilled water for ten minutes in turn, and dried. Then, the prepared coating working solution is evenly sprayed on the dried aluminum sheet to form a uniform antibacterial coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com