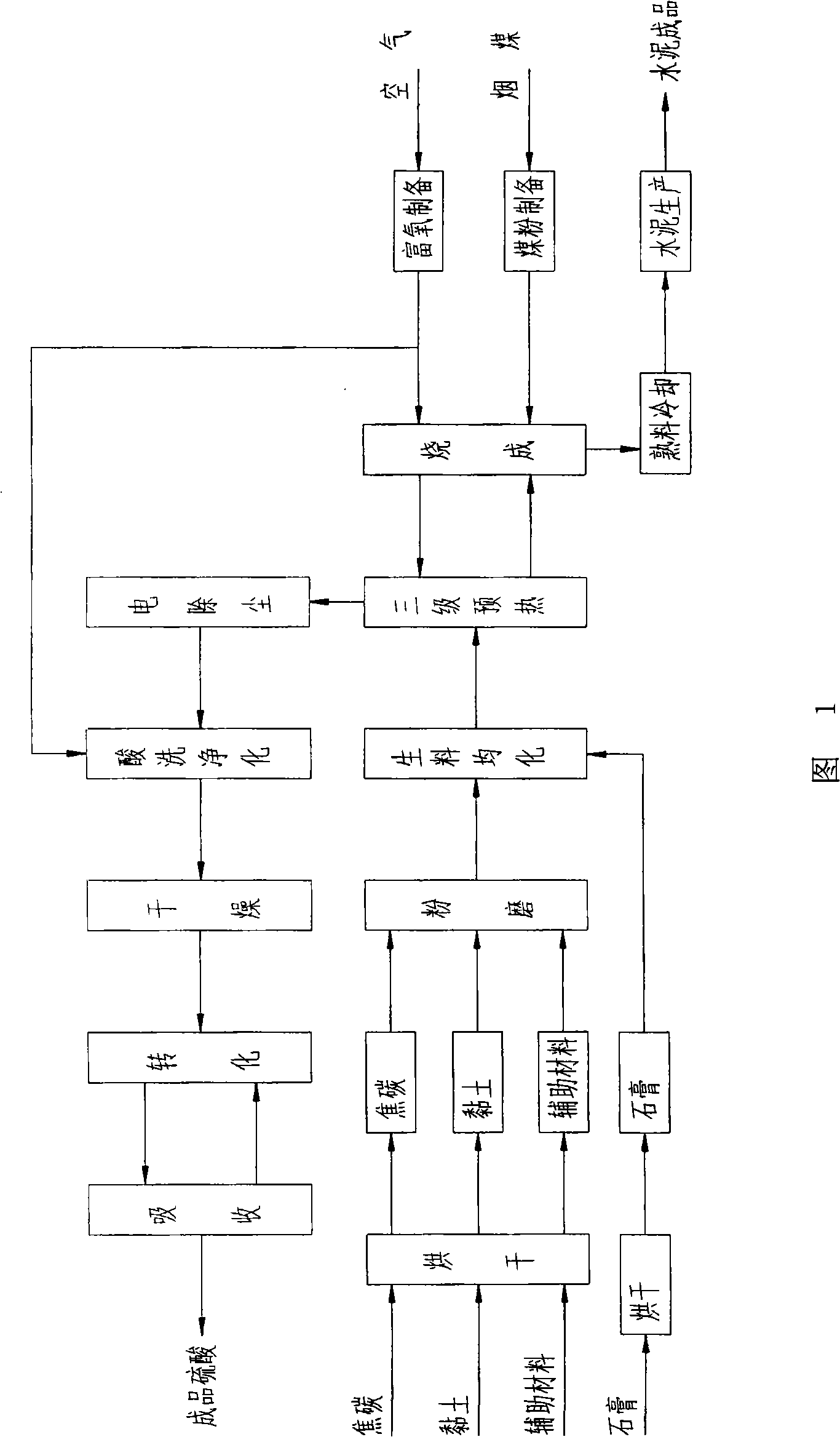

Process for producing sulfate acid from gypsum

A technology of gypsum and sulfuric acid, applied in the direction of sulfur trioxide/sulfuric acid, energy input, etc., can solve the problems of high construction investment, low gas concentration, increased production cost, etc., to solve operational difficulties, solve secondary pollution, and reduce heat energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Dry the waste residue phosphogypsum or natural gypsum dihydrate produced by phosphoric acid to less than 10.0% water content, and store the natural anhydrite without drying (but crushing and grinding). Auxiliary materials such as coke and clay are stored and ground after drying. Various raw materials are batched according to a certain ratio and then enter the raw meal homogenization warehouse. The rate value of gypsum raw meal is controlled as follows: the lime saturation coefficient KH is 0.80-0.97, the silicic acid rate SM is 2.40-4.50, and the iron rate IM is 2.10-3.30.

[0016] 2. The raw meal in the homogenization warehouse is sent to the three-stage cyclone preheating system after being homogenized by multi-point feeding. The raw meal is raised from about 50 °C in the homogenization room to 550--660 °C and enters the kiln. The temperature of the gas coming out of the kiln and entering the preheater is 650--850°C, and it becomes about 300°C after preheating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com