Process for preparing phenetidine and amino phenol by using mixture of nitrophenetol and nitrophenol as raw materials

A technology for nitrophenethyl ether and aminophenethyl ether, which is applied in the field of preparing aminophenethyl ether and aniline, can solve the problems of increased pretreatment cost, high energy consumption in the production process, a large amount of process waste water, etc., and can save pretreatment steps and equipment. The effect of low corrosiveness and safe process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The main process equipment is: stirred tank reactor, blade filter device, solvent recovery device, continuous rectification tower.

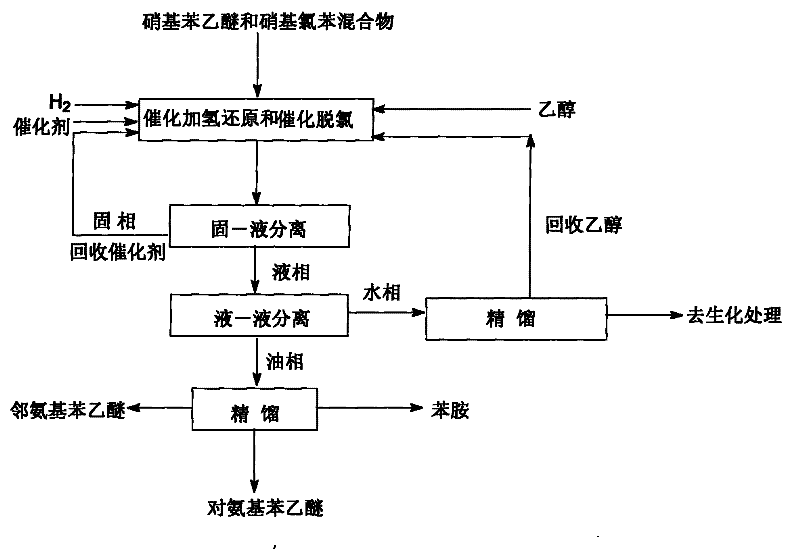

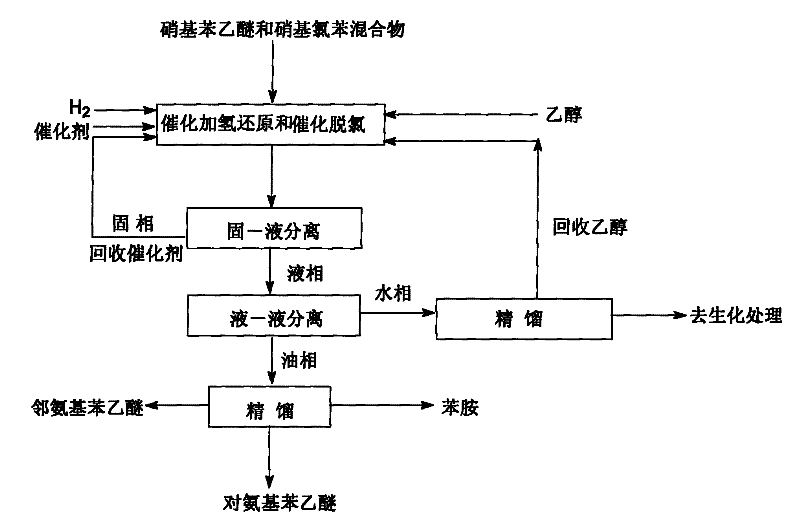

[0030] A kind of technology that prepares aminophenetole and aniline with nitrophenetole and nitrochlorobenzene mixture as raw material, described process step is as follows:

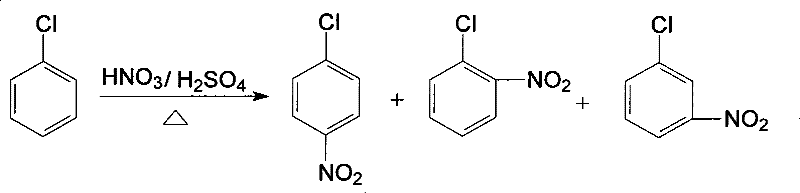

[0031] (1) Catalytic hydrogenation and catalytic dechlorination reaction: In a stirred tank reactor for catalytic hydrogenation and catalytic dechlorination reduction, ethanol is used as a solvent, and a mixture of nitrophenethyl ether and nitrochlorobenzene is used as a raw material, and the raw material nitro The consumption ratio of phenetole and nitrochlorobenzene mixture and ethanol is 1g: 0.5ml, and described nitrophenetole is p-nitrophenetole and o-nitrophenetole, and described nitrochlorobenzene is o-nitro Chlorobenzene, m-nitrochlorobenzene and p-nitrochlorobenzene, the percentage by weight of various ingredients in the raw material mixture is 95.0% for nit...

Embodiment 2

[0036] The main process equipment is: stirred tank reactor, blade filter device, solvent recovery device, batch rectification tower.

[0037] A kind of technology that prepares aminophenetole and aniline with nitrophenetole and nitrochlorobenzene mixture as raw material, described process step is as follows:

[0038] (1) Catalytic hydrogenation and catalytic dechlorination reaction: In a stirred tank reactor for catalytic hydrogenation and catalytic dechlorination reduction, ethanol is used as a solvent, and a mixture of nitrophenethyl ether and nitrochlorobenzene is used as a raw material, and the raw material nitro The consumption ratio of phenetole and nitrochlorobenzene mixture and ethanol is 1g: 3ml, and described nitrophenetole is p-nitrophenetole and o-nitrophenetole, and described nitrochlorobenzene is o-nitrochloride Benzene and m-nitrochlorobenzene and p-nitrochlorobenzene, the percentage by weight of various components in the raw material mixture is 98.5% for nitrop...

Embodiment 3

[0043] The main process equipment is: stirred tank reactor, blade filter device, solvent recovery device, continuous rectification tower.

[0044] A kind of technology that prepares aminophenetole and aniline with nitrophenetole and nitrochlorobenzene mixture as raw material, described process step is as follows:

[0045] (1) Catalytic hydrogenation and catalytic dechlorination reaction: In a stirred tank reactor for catalytic hydrogenation and catalytic dechlorination reduction, ethanol is used as a solvent, and a mixture of nitrophenethyl ether and nitrochlorobenzene is used as a raw material, and the raw material nitro The consumption ratio of phenetole and nitrochlorobenzene mixture and ethanol is 1g: 3ml, and described nitrophenetole is p-nitrophenetole and o-nitrophenetole, and described nitrochlorobenzene is o-nitrochloride Benzene, m-nitrochlorobenzene and p-nitrochlorobenzene, the percentage by weight of various components in the raw material mixture is 96.0% for nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com