Method for hydrolyzing propolis flavonoid glycosideby by naringinase

A gum flavonoid glycoside and naringinase technology, which is applied in the field of propolis flavonoid glycoside hydrolysis by naringinase, to achieve the effects of expanding the application range, improving antioxidant performance, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

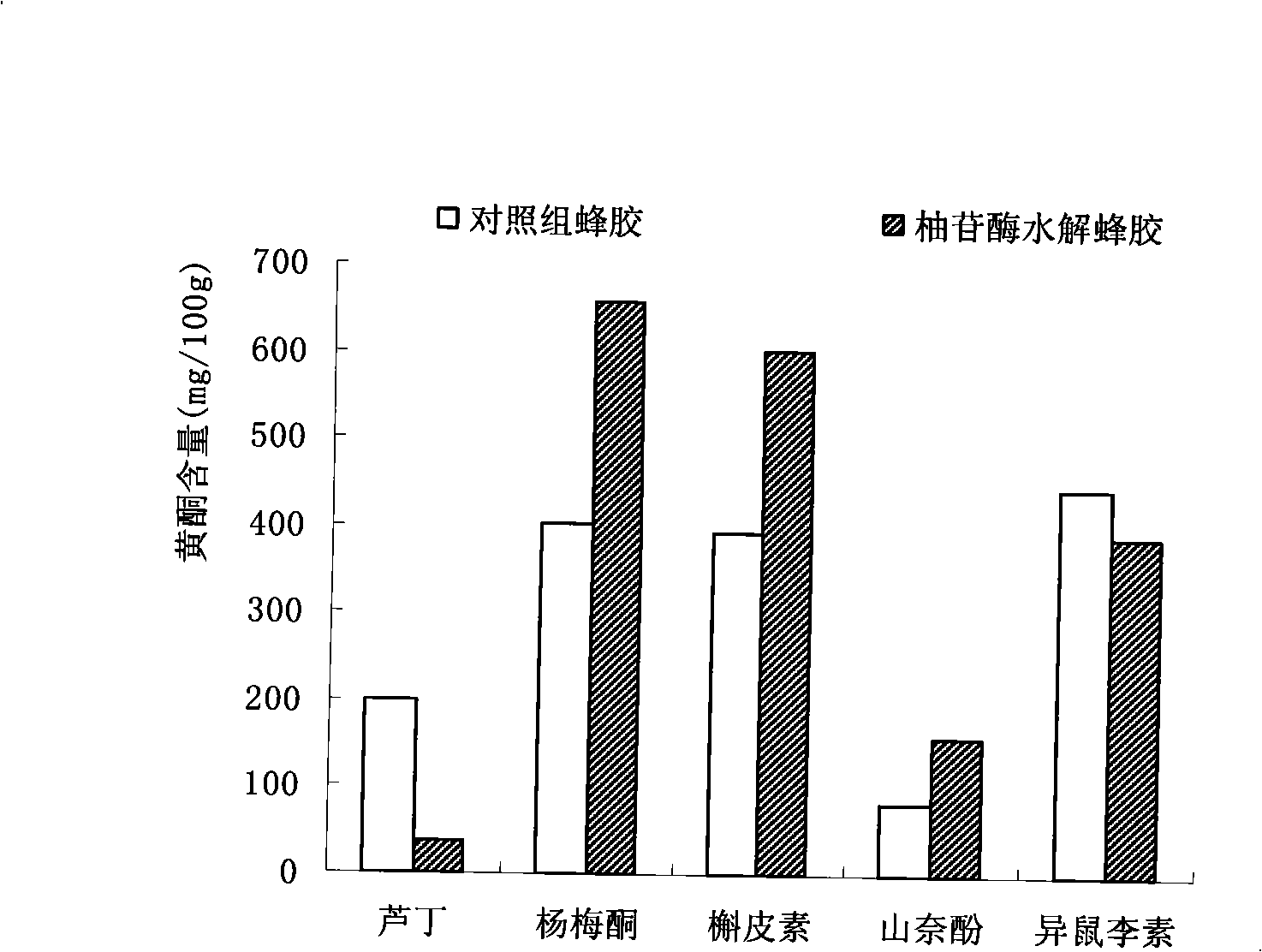

[0018] Take 100 mg of propolis, dissolve it in 200 mL of distilled water, add β-glucosidase, xylanase, cellulase, pectinase, α-amylase for compound enzyme pretreatment, and the enzyme dosage is 10U / mg, 1500U / mg, respectively. mL, 9U / mL, 50U / mL, 1.5U / mL, pretreatment at pH 5.0, temperature 50°C for 6 hours, adding a certain amount of naringinase for conversion, controlling the enzyme concentration to 30U / mg, pH 4.5 , the temperature is 50°C, the enzymolysis time is 24 hours, and the solution is always kept uniform during the reaction process. After enzymatic hydrolysis, add absolute ethanol to make the final concentration reach 60% to inactivate the enzyme. The flavonoid glycoside rutin in propolis obtained under this enzymolysis condition was reduced from 198.4mg / 100g before enzymolysis to 36.3mg / 100g after enzymolysis, and the hydrolysis rate reached 81.7%. The contents of corticosteroids and kaempferol all increased, respectively by 53.2%, 63.2% and 95.9% (seeing table 1, ...

Embodiment 2

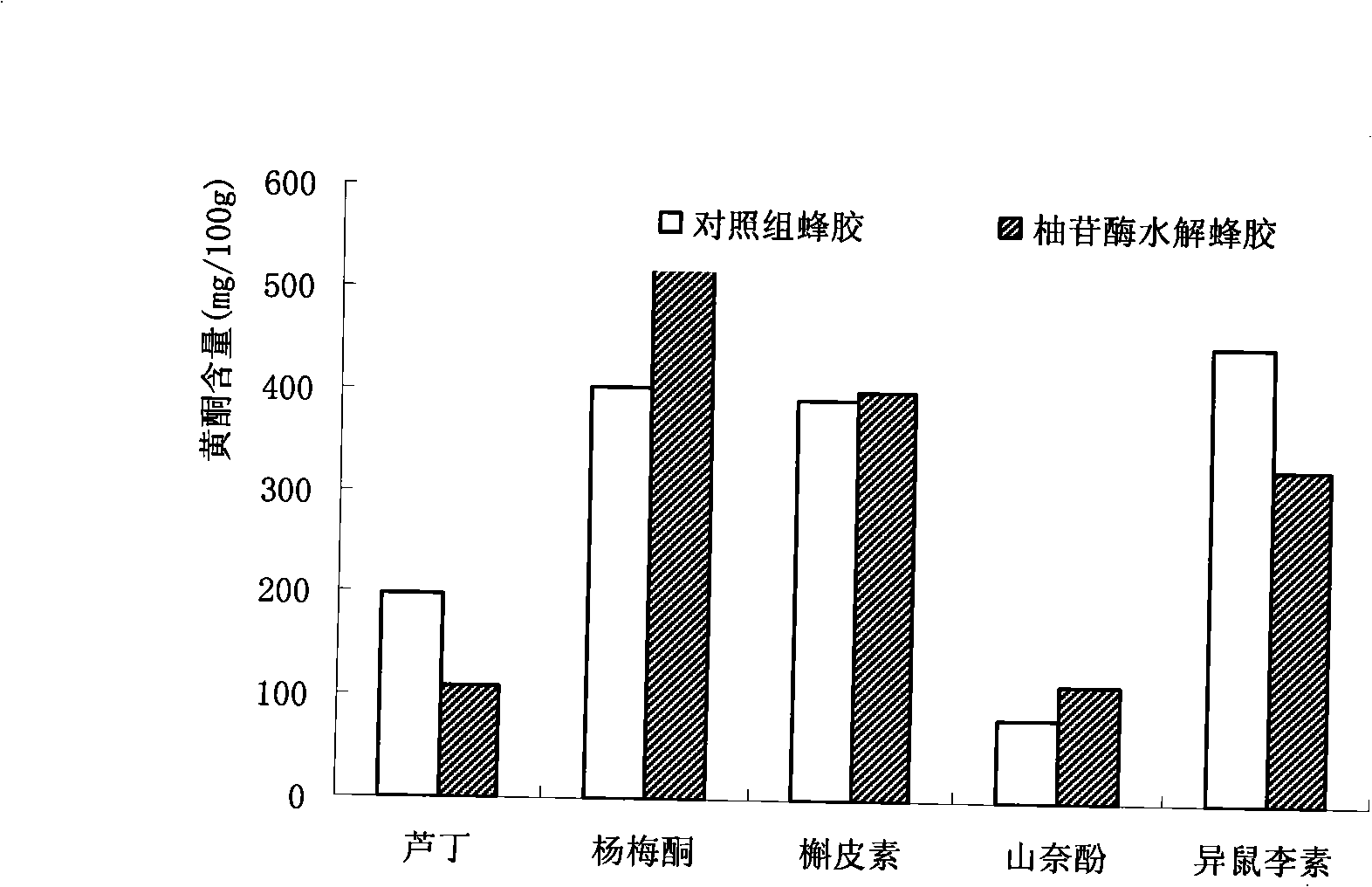

[0026] Take 200mg of propolis, dissolve it in 200mL of distilled water, carry out compound enzyme pretreatment as in Example 1, add a certain amount of naringinase for conversion, control the enzyme concentration to 10U / mg, pH value 4.0, temperature 35°C, enzymolysis time 9 hours , keep the solution uniform throughout the reaction. After enzymatic hydrolysis, add absolute ethanol to make the final concentration reach 60% to inactivate the enzyme. The flavonoid glycoside rutin in propolis obtained under this enzymolysis condition was reduced from 198.4mg / 100g before enzymolysis to 109.7mg / 100g after enzymolysis, and the hydrolysis rate reached 44.7%. The contents of corticosteroids and kaempferol all increased, respectively by 1.8%, 30.2% and 39.3% (seeing table 3, image 3 ).

[0027] Table 3 Contents of five flavonoids in propolis before and after enzymatic hydrolysis (mg / 100g)

[0028]

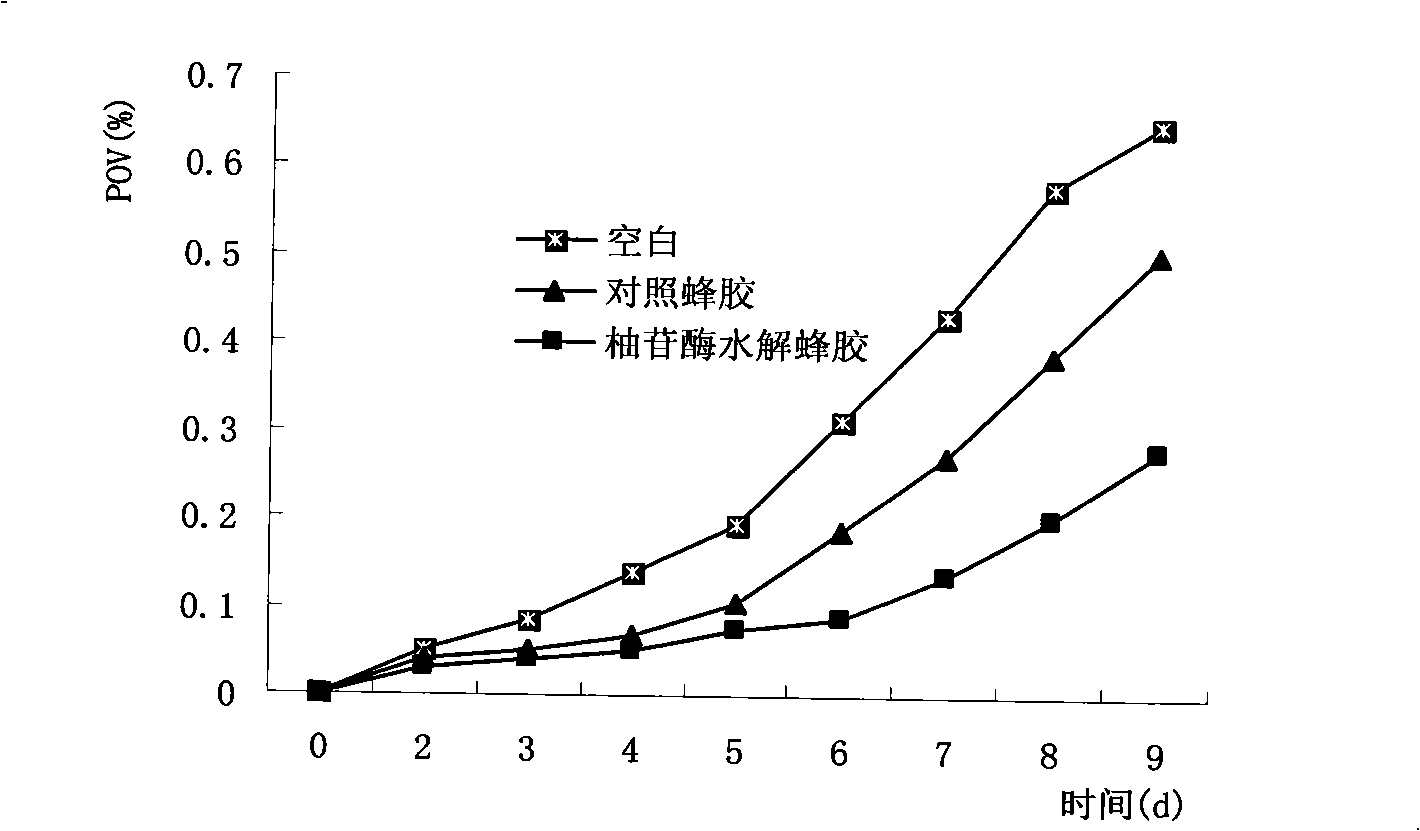

[0029] The POV of the propolis hydrolyzate on the 9th day was 0.4368%, while the P...

Embodiment 3

[0033] Take 800 mg of propolis, dissolve it in 200 mL of distilled water, carry out compound enzyme pretreatment as in Example 1, add a certain amount of naringinase for conversion, control the enzyme concentration at 5 U / mg, pH value 6.5, temperature at 60°C, and enzymatic hydrolysis time for 6 hours , keep the solution uniform throughout the reaction. After enzymatic hydrolysis, add absolute ethanol to make the final concentration reach 60% to inactivate the enzyme. The flavonoid glycoside rutin in propolis obtained under this enzymolysis condition was reduced from 198.4mg / 100g before enzymolysis to 136.8mg / 100g after enzymolysis, and the hydrolysis rate reached 31.0%. The contents of corticosteroids and kaempferol all increased, respectively by 5.3%, 18.8% and 20.2% (seeing table 5, Figure 5 ).

[0034] Table 5 Contents of five flavonoids in propolis before and after enzymatic hydrolysis (mg / 100g)

[0035]

[0036] The POV of the propolis hydrolyzate on the 9th day w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrolysis rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com