Low-power consumption double module integrated humidity sensitive chip with heating function and its manufacture method

A technology that integrates humidity and sensitive chips. It is used in the manufacture of microstructure devices, semiconductor/solid-state device manufacturing, decorative arts, etc. It can solve the problem that it is difficult to make heating resistors directly below the capacitors, humidity sensors do not have heating functions, and semiconductor processes are incompatible, etc. problems, to reduce the impact of rain and solar radiation, improve reliability and stability, and solve the effect of large heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

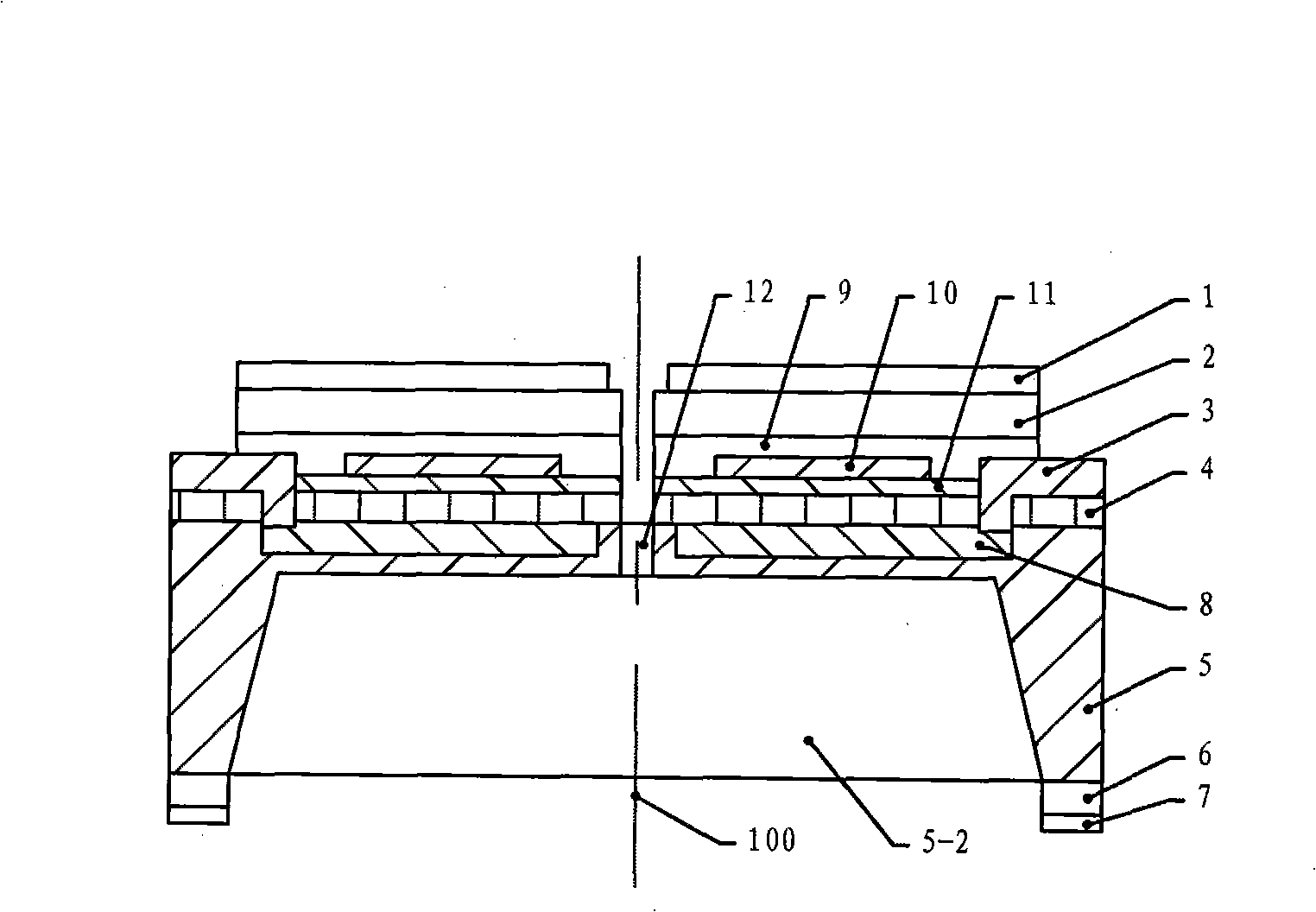

[0016] Embodiment 1: The structure of the low power consumption dual-module integrated humidity sensitive chip with heating function described in this embodiment is as follows: there is a thermal isolation through groove 12 on the symmetry axis of the sensor structure substrate 5, and the sensor structure substrate There are two humidity sensor modules on the upper surface of 5. The two humidity sensor modules have the same structure and are symmetrically arranged with the heat isolation through groove 12 as the axis. Each humidity sensor module is the first from bottom to top. The oxide insulating layer 4, the first silicon nitride insulating layer 11, the insulating passivation layer 9, the humidity sensitive medium layer 2 and the porous capacitor upper plate 1, the heating resistor 8 is located on the first oxide insulating layer 4 and the sensor structure substrate 5, the capacitor lower plate 10 is located between the first silicon nitride insulating layer 11 and the insu...

specific Embodiment approach 2

[0032] Embodiment 2. The difference between this embodiment and the dual-module integrated humidity sensitive chip with heating function and low power consumption described in Embodiment 1 is that there are also silicon cups 5-2 and silicon cups on the bottom surface of the microstructure substrate 5. Peripheral fixation.

[0033] In this embodiment, the silicon cup 5-2 added on the bottom surface of the sensor microstructure substrate 5 and the fixed support structure around the silicon cup can not only make small-sized chips, but also reduce heat loss and improve the dehumidification efficiency of the heating resistor used for thermal purification. .

[0034] The lower surface of the peripheral fixed support of the silicon cup described in this embodiment is covered with a second insulating oxide layer 6 and a second insulating silicon nitride layer 7 in sequence, the second insulating oxide layer 6 is a silicon dioxide film, and the The thickness of the second oxide insula...

specific Embodiment approach 3

[0035]Specific implementation mode three: The manufacturing method of the dual-module integrated humidity-sensitive chip with heating function and low power consumption described in this implementation mode is as follows:

[0036] Step 1: Carry out oxidation, coating and anisotropic etching on the monocrystalline silicon wafer to obtain the sensor structure substrate 5;

[0037] Step 2, making two heating resistors 8 on the upper surface of the sensor structure substrate 5, the two heating resistors 8 are symmetrical to the symmetry axis 100 of the sensor structure substrate 5;

[0038] Step 3, making a humidity sensitive capacitor right above the two heating resistors 8;

[0039] Step 4: Fabricate thermal isolation through-slots 12 on the symmetry axis 100 of the monocrystalline silicon thin-film silicon wafer through MEMS micromachining technology, so that the two heating resistors 8 are symmetrically located on both sides of the thermal isolation through-slots 12 .

[0040...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com