Levo-cetirizine hydrochloride orally disintegrating tablets and preparation method thereof

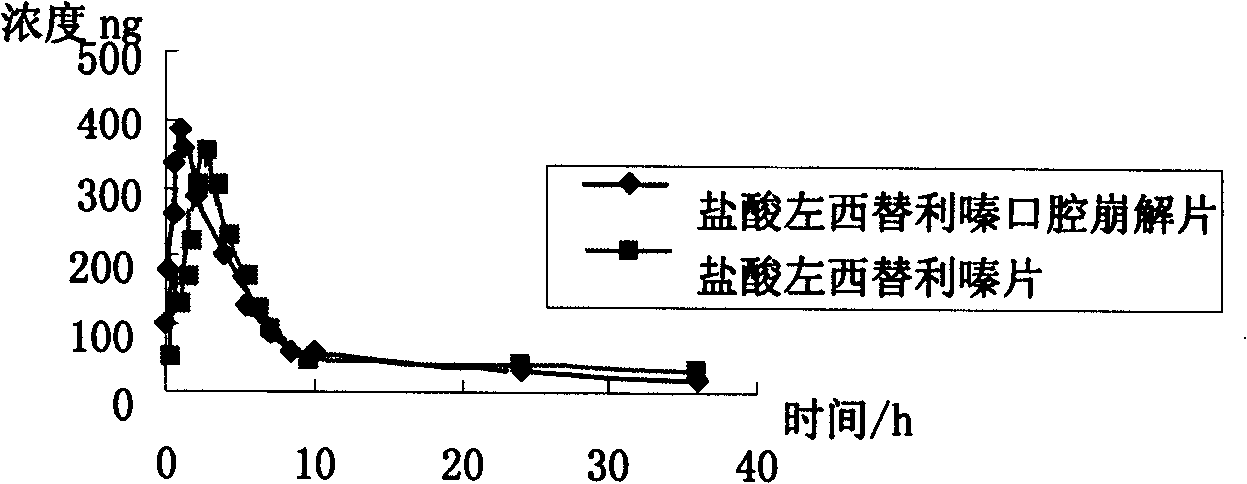

A technology of levocetirizine hydrochloride and orally disintegrating tablets, applied in the field of levocetirizine hydrochloride orally disintegrating tablets and its preparation, can solve the problems of slow drug onset, low drug bioavailability, and hard appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Main drug: Levocetirizine hydrochloride 5g

[0016] Filler: Microcrystalline Cellulose 50g

[0017] Mannitol 45g

[0018] Flavoring: Sucralose 1.5g

[0019] Disintegrant: cross-linked polyvinylpyrrolidone 20g

[0020] Lubricant: Magnesium Stearate 0.2%

[0021] A total of 1000 pieces were made.

[0022] Preparation:

[0023] (1) pulverizing levocetirizine hydrochloride and auxiliary materials, passing levocetirizine hydrochloride through a 200 mesh sieve, and auxiliary materials passing through a 100 mesh sieve respectively, for subsequent use;

[0024] (2) Take by weighing the levocetirizine hydrochloride and microcrystalline cellulose, mannitol, cross-linked polyvinylpyrrolidone, sucralose etc. of prescription quantity, earlier levocetirizine hydrochloride and microcrystalline cellulose Incremental method to mix evenly, then fully mix with mannitol, then add the remaining excipients and mix evenly;

[0025] (3) wet granulation with water;

[0026] (4) ...

Embodiment 2

[0033] Main drug: Levocetirizine hydrochloride 5g

[0034] Filler: Microcrystalline Cellulose 70g

[0035] Mannitol 30g

[0036] Flavoring agent: Aspartame 1.0g

[0037] Sweet orange essence 0.7g

[0038] Disintegrant: low-substituted hydroxypropyl cellulose 25g

[0039] Lubricant: Magnesium Stearate 0.2%

[0040] A total of 1000 pieces were made.

[0041] Preparation:

[0042] (1) pulverizing levocetirizine hydrochloride and auxiliary materials, passing levocetirizine hydrochloride through a 200 mesh sieve, and auxiliary materials passing through a 100 mesh sieve respectively, for subsequent use;

[0043] (2) Take by weighing the levocetirizine hydrochloride and microcrystalline cellulose, mannitol, low-substituted hydroxypropyl cellulose, aspartame, sweet orange essence etc. of prescription quantity, levocetirizine hydrochloride and The microcrystalline cellulose is mixed evenly by the method of equal increment, and then fully mixed with mannitol, and ...

Embodiment 3

[0052] Main drug: Levocetirizine hydrochloride 5g

[0053] Filler: Microcrystalline Cellulose 60g

[0054] Lactose 20g

[0055] Flavoring agent: Stevia 1.0g

[0056] Disintegrant: croscarmellose sodium 25g

[0057] Lubricant: Magnesium Stearate 0.2%

[0058] A total of 1000 pieces were made.

[0059] Preparation:

[0060] (1) pulverizing levocetirizine hydrochloride and auxiliary materials, passing levocetirizine hydrochloride through a 200 mesh sieve, and auxiliary materials passing through a 100 mesh sieve respectively, for subsequent use;

[0061] (2) Take by weighing prescription amount of levocetirizine hydrochloride and microcrystalline cellulose, lactose, croscarmellose sodium, stevioside, etc., first levocetirizine hydrochloride and microcrystalline cellulose, etc. Incremental volume method to mix evenly, then fully mix with lactose, then add the remaining excipients and mix evenly;

[0062] (3) carry out wet granulation with 50% ethanol solution;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com