Method for preparing cuboid indium oxide single crystal

A cuboid-shaped, indium oxide technology is applied in the field of preparation of cuboid-shaped indium oxide single crystals, which can solve the problems of easy collapse and difficult control of morphology, and achieve the effects of low cost, uniform and controllable morphology, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

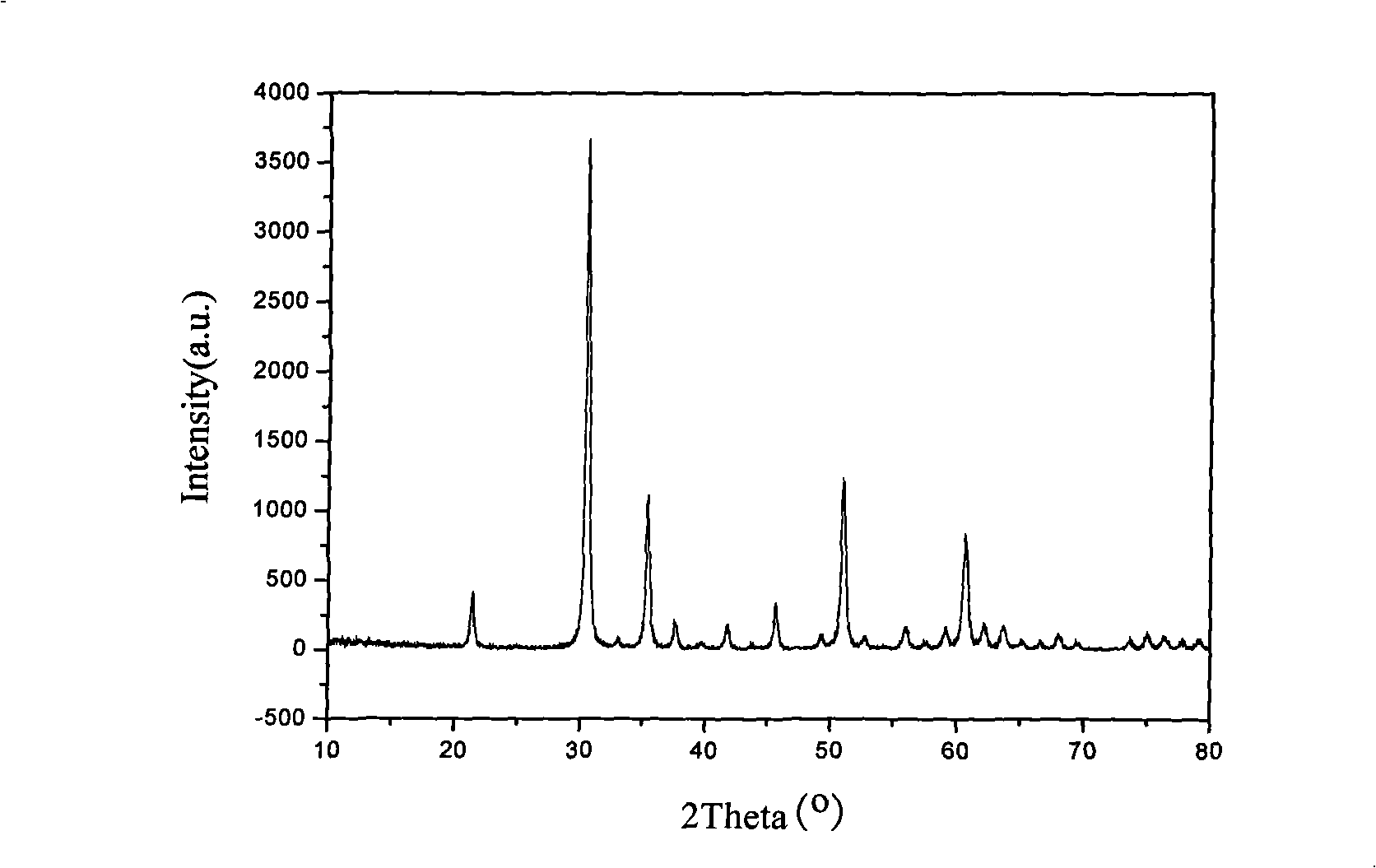

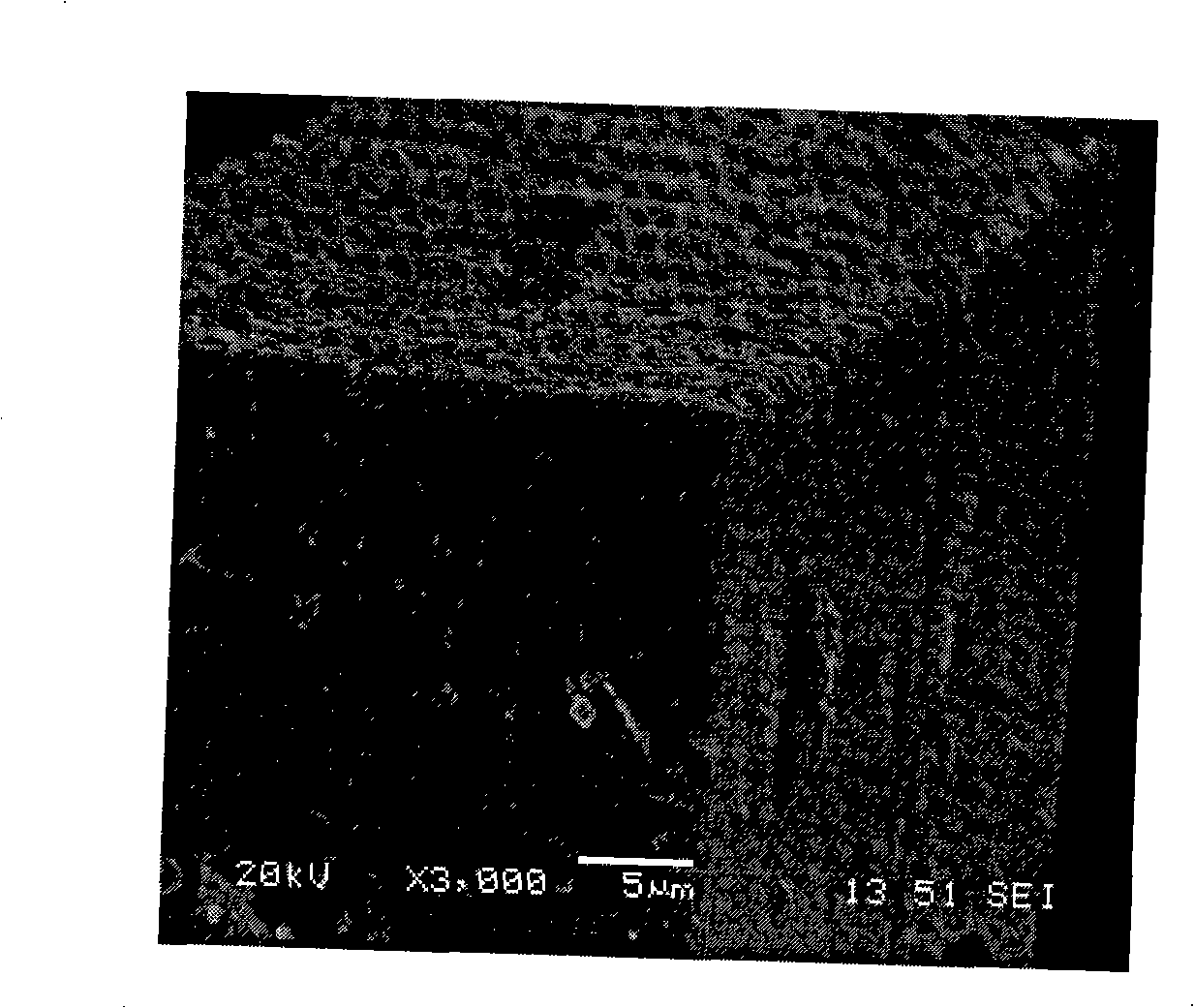

Image

Examples

Embodiment 1

[0023] The preparation method of the cuboid indium oxide single crystal provided in this embodiment includes the following steps:

[0024] a) Preparation of morphology control agent: add ammonia water, n-heptanol, cyclohexylamine and nonanoic acid in sequence according to the ratio, and mix and stir at 0°C for 5 minutes, wherein: the volume ratio of ammonia water, n-heptanol, cyclohexylamine and nonanoic acid is 3:20:20:20;

[0025] b) Preparation of indium salt solution: adding indium chloride compound into distilled water, stirring at 0°C to dissolve it completely to form a transparent solution, wherein: the molar concentration of indium ions is 0.077mol / L;

[0026] c) Preparing the precursor: at 0°C, add the above-prepared indium salt solution dropwise to the above-prepared morphology control agent, and the dropping rate is controlled at 60 drops / min; after dropping, stir for 5 minutes; then transfer to the reaction kettle placed in a melting furnace and heated to 180°C fo...

Embodiment 2

[0031] The preparation method of the cuboid indium oxide single crystal provided in this embodiment includes the following steps:

[0032] a) Preparation of morphology control agent: add ammonia water, n-heptanol, cyclohexylamine and nonanoic acid in sequence according to the ratio, and mix and stir at -5°C for 5 minutes, wherein: the volume ratio of ammonia water, n-heptanol, cyclohexylamine and nonanoic acid 3:20:20:20;

[0033] b) Preparation of indium salt solution: add indium nitrate compound into distilled water, stir at -5°C to dissolve it completely, and form a transparent solution, wherein: the molar concentration of indium ions is 0.077mol / L;

[0034] c) Preparing the precursor: at -5°C, add the above-prepared indium salt solution dropwise to the above-prepared morphology control agent, and the dropping rate is controlled at 60 drops / min; after dropping, stir for 5 minutes; then transfer to the reaction Put it in a furnace and heat it to 200°C, and keep it warm for ...

Embodiment 3

[0039] The preparation method of the cuboid indium oxide single crystal provided in this embodiment includes the following steps:

[0040] a) Preparation of morphology control agent: add ammonia water, n-heptanol, cyclohexylamine and nonanoic acid in sequence according to the ratio, and mix and stir at 5°C for 5 minutes, wherein: the volume ratio of ammonia water, n-heptanol, cyclohexylamine and nonanoic acid is 3:20:20:20;

[0041] b) Preparation of indium salt solution: adding indium acetate compound into distilled water, stirring at 5°C to dissolve it completely to form a transparent solution, wherein: the molar concentration of indium ions is 0.077mol / L;

[0042] c) Preparing the precursor: at 5°C, add the above-prepared indium salt solution dropwise to the above-prepared morphology control agent, and the dropping rate is controlled at 60 drops / min; after dropping, stir for 5 minutes; then transfer to the reaction kettle placed in a melting furnace and heated to 150°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com