Carbonaceous solid acid catalyst prepared by direct sulphonation of biomass

A solid acid catalyst and biomass technology, applied in the direction of physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of disappearing price advantages of carbon catalysts, and achieve Good recovery and reuse effect, rich and renewable raw material resources, and the effect of improving the efficiency of esterification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

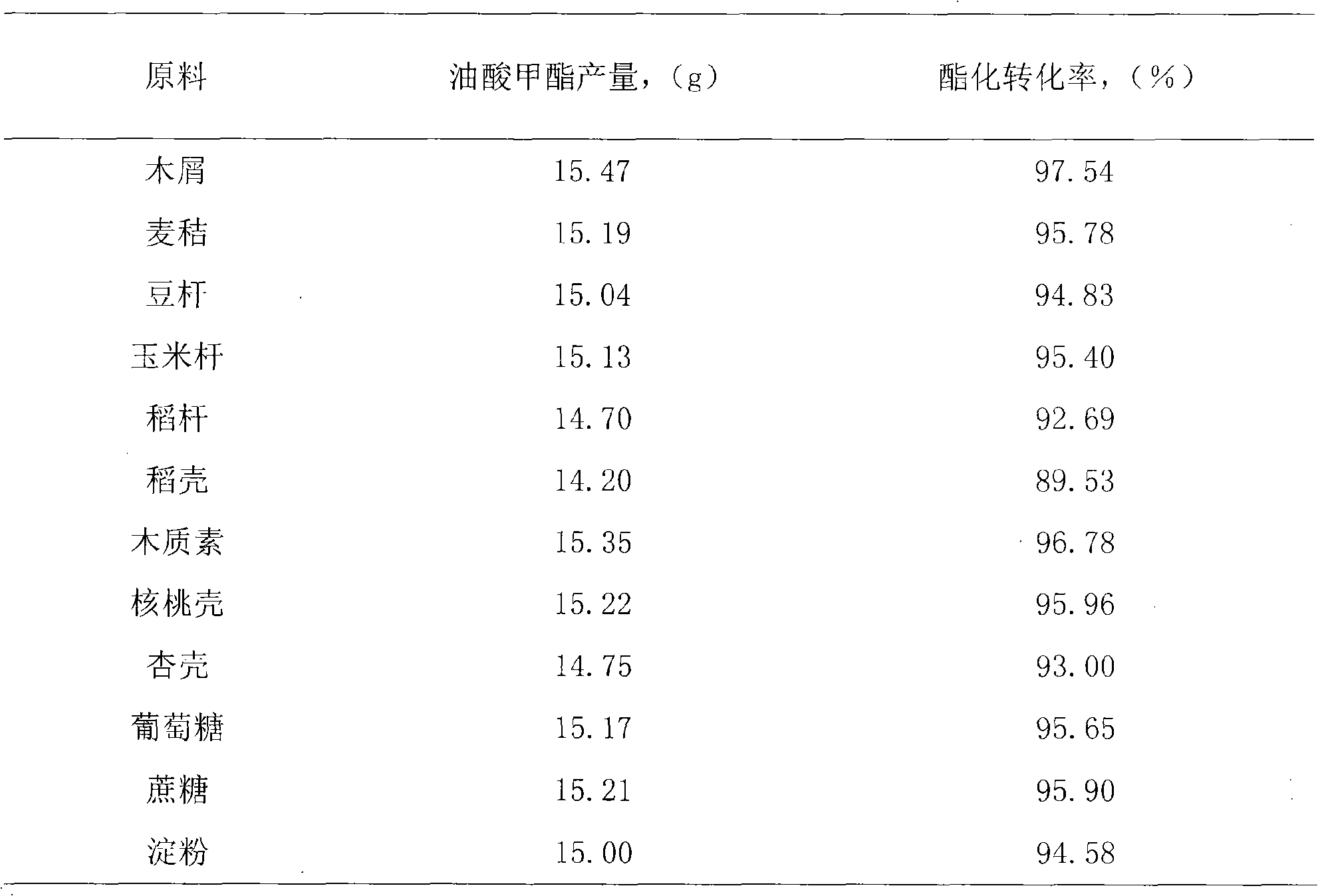

[0021] Weigh 14g dry wood chips, wheat straw, bean stalks, corn stalks, rice stalks, lignin, rice husks, walnut shells, apricot shells, glucose, sucrose, and starch, and directly add 140g of concentrated sulfuric acid to them, and pass them under nitrogen protection. Carry out the sulfonation reaction at ℃, keep the stirring rate at about 600r / min, after 4 hours of reaction, add the reaction mixture into 300ml distilled water and stir thoroughly, then filter, dry, and wash repeatedly with 100℃ distilled water until the filtrate is completely It is neutral and can be dried to obtain a carbonaceous solid acid catalyst.

[0022] Catalytic effect: put 14g of methanol, 15.86g of oleic acid and 1g of carbonaceous catalyst in the continuous distillation-water separation esterification device to carry out esterification reaction at 90°C (reboiler temperature is 85°C), after 2 hours of reaction Obtain methyl oleate yield and esterification conversion rate as shown in Table 1.

[0023]...

Embodiment 2

[0026] Weigh 14g of dried sawdust and directly add 98g of concentrated sulfuric acid, pass it under nitrogen protection, carry out sulfonation reaction at 100°C, keep the stirring rate at about 600r / min, after reacting for 1h, add the reaction mixture into 300ml of distilled water and stir well , then filtered, dried, and washed repeatedly with distilled water at 100°C until the filtrate was completely neutral, and dried to obtain a carbonaceous solid acid catalyst.

[0027] Catalytic effect: Catalytic effect: 14g of methanol, 15.86g of oleic acid and 1g of carbonaceous catalyst are loaded into the continuous distillation-water separation esterification device to carry out esterification reaction at 70°C (reboiler temperature is 85°C), reaction 6 After one hour, 15.39 g of methyl oleate was obtained, and the esterification rate was 97.03%.

Embodiment 3

[0029] Weigh 14g of dry sawdust and directly add 140g of concentrated sulfuric acid, pass it under nitrogen protection, carry out sulfonation reaction at 50°C, and keep the stirring speed at about 600r / min. After 3 hours of reaction, add the reaction mixture into 300ml of distilled water and stir well. Then filter and dry, and then repeatedly wash with distilled water at 100° C. until the filtrate is completely neutral, and then dry to obtain a carbonaceous solid acid catalyst.

[0030] Catalytic effect: Catalytic effect: 14g of methanol, 15.86g of oleic acid and 0.8g of carbonaceous catalyst are charged into the continuous rectification-water separation esterification device to carry out esterification reaction at 100°C (reboiler temperature is 85°C), and the reaction One hour later, 15.26 g of methyl oleate was obtained, and the esterification rate was 96.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com