Apparatus and method for producing sludge gas with organic castoff

A technology of organic waste and biogas, which is applied in the preparation of organic fertilizers, organic fertilizers, waste fuels, etc., can solve the problems of low efficiency, long cycle, and lack of methods for preparing biogas, so as to improve the efficiency of biogas fermentation and reduce pretreatment Cost, the effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

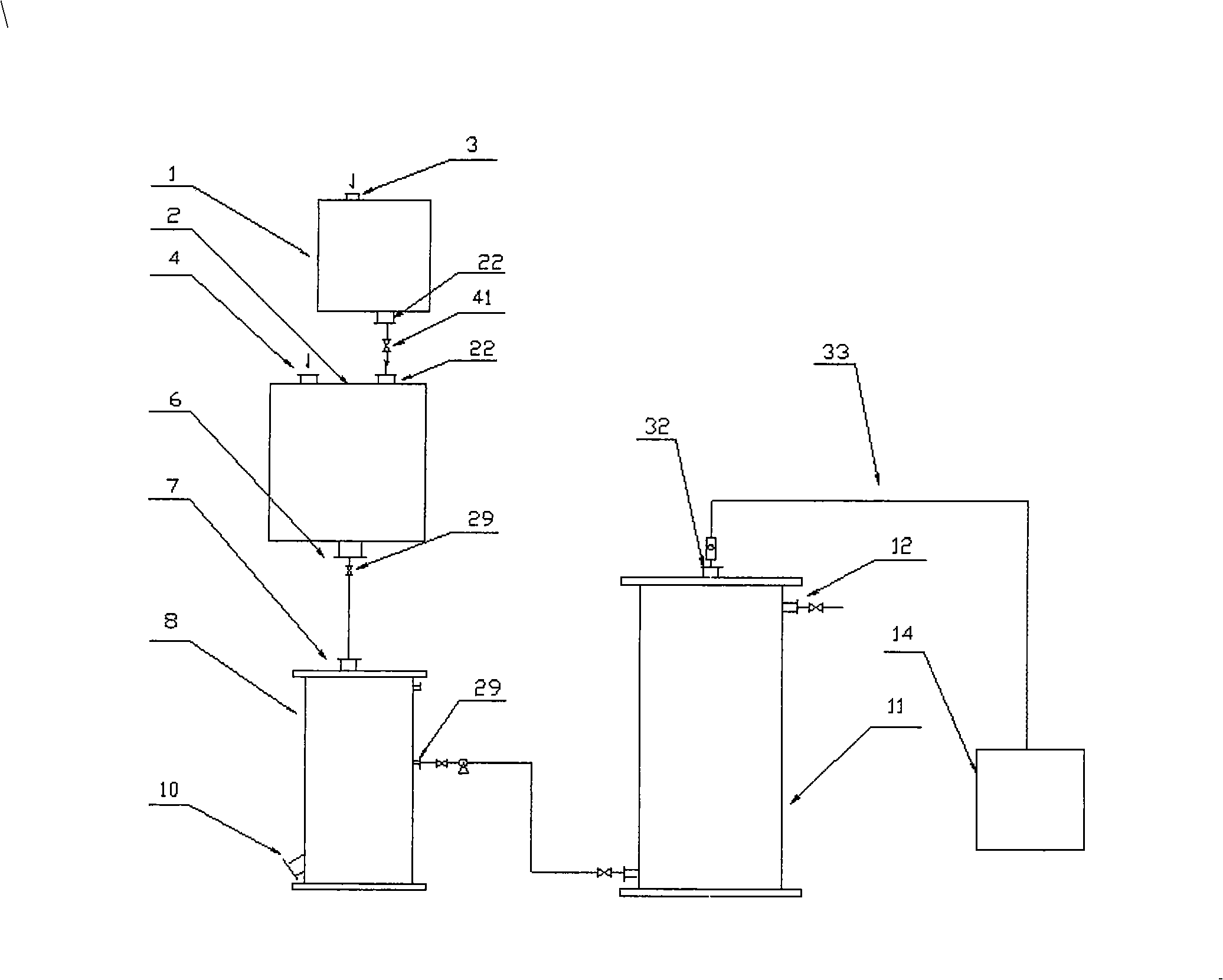

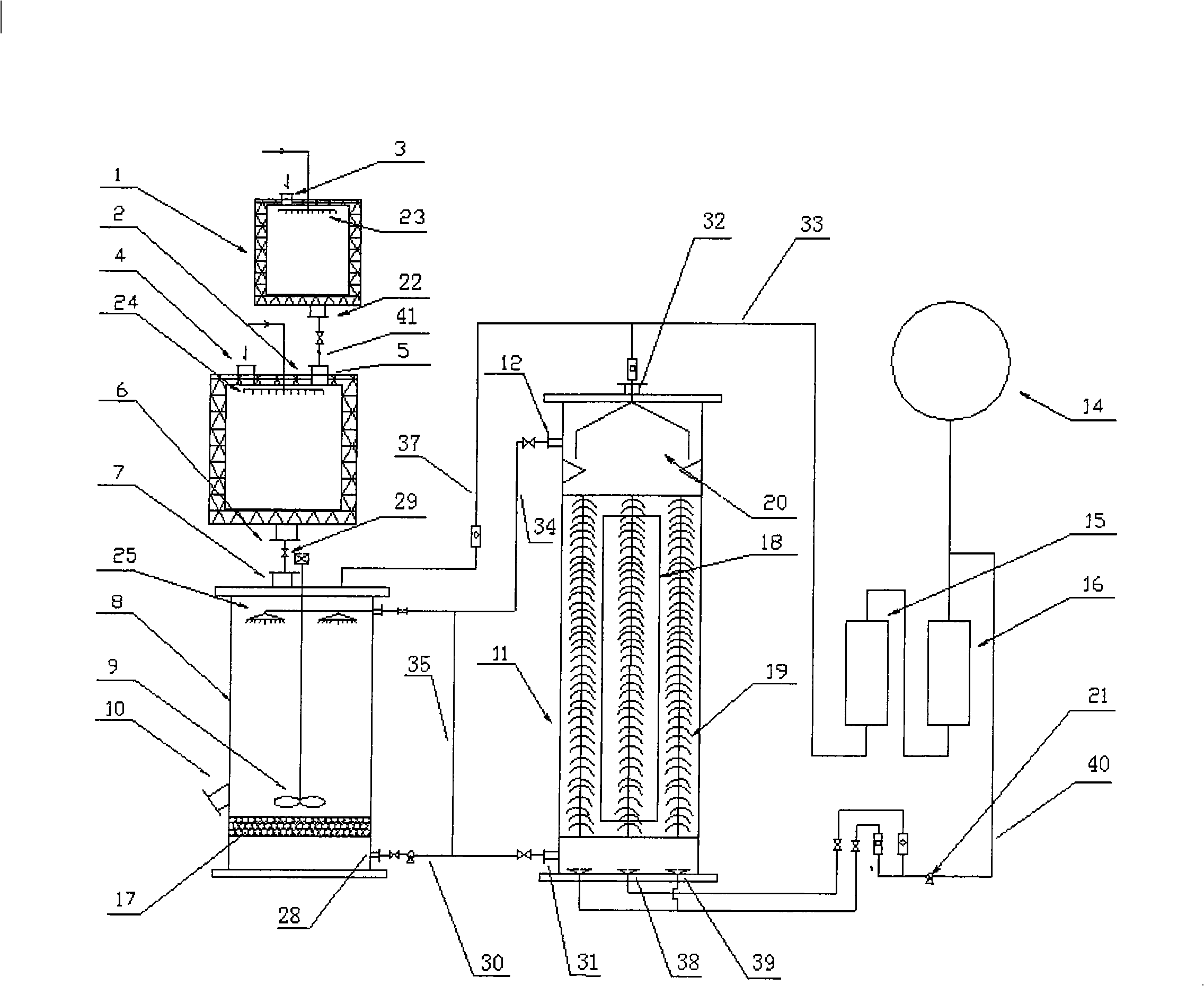

[0069] figure 1 A device structure for preparing biogas from organic waste is provided, the device includes a biogas collector 14 for storing biogas, a methane-producing reactor 11 for fermenting and preparing biogas, and is characterized in that it also includes a device for An acid processor 1 for acid treatment of organic waste, an alkali processor 2 for alkali treatment of organic waste, and an acid generating reactor 8;

[0070] The acid processor 1 is provided with an acid treatment feed port 3 and an acid treatment discharge port 22; the alkali processor 2 is provided with an alkali treatment feed port 4, an acid material injection port 5 and an alkali treatment discharge port 6; The acid-generating reactor 8 is a closed container, which is provided with an acid-generating feed inlet 7, an acid-generating discharge port 10, and an acid-generating liquid outlet 28;

[0071] The acid treatment outlet 22 of the acid processor 1 communicates with the acid material injectio...

Embodiment 2

[0083] The device of this embodiment is the same as that of Embodiment 1 except that the acid processor 1 and the alkali processor 2 are heat-preserving acid processors and heat-insulating alkali processors with insulation layers on the wall.

[0084] The method for preparing biogas by using the above-mentioned device with medicinal dregs is as follows:

[0085] 1) Under normal pressure, first add the medicinal dregs and hydrochloric acid solution that have been cooked at high temperature and have a temperature of 98° C. according to the solid-to-liquid ratio of mixing 1 gram of medicinal dregs and 15 ml of hydrochloric acid into the heat preservation acid processor 1 for acid treatment for 24 hours. The concentration of the hydrochloric acid solution is 0.1N, because the heat preservation acid processor wall is provided with an insulation layer, so the temperature inside can be kept at 40-95°C all the time;

[0086] Simultaneously, the medicine dregs of the same amount and KO...

Embodiment 3

[0092] This embodiment provides another device structure for preparing biogas using cooking dregs, which is improved on the basis of the device in Example 2;

[0093] First, in order to make the acid solution and the alkali solution more uniformly mixed with the medicinal residues, a first shower 23 and a second shower 24 are respectively set in the heat preservation acid processor 1 and the heat preservation alkali processor 2;

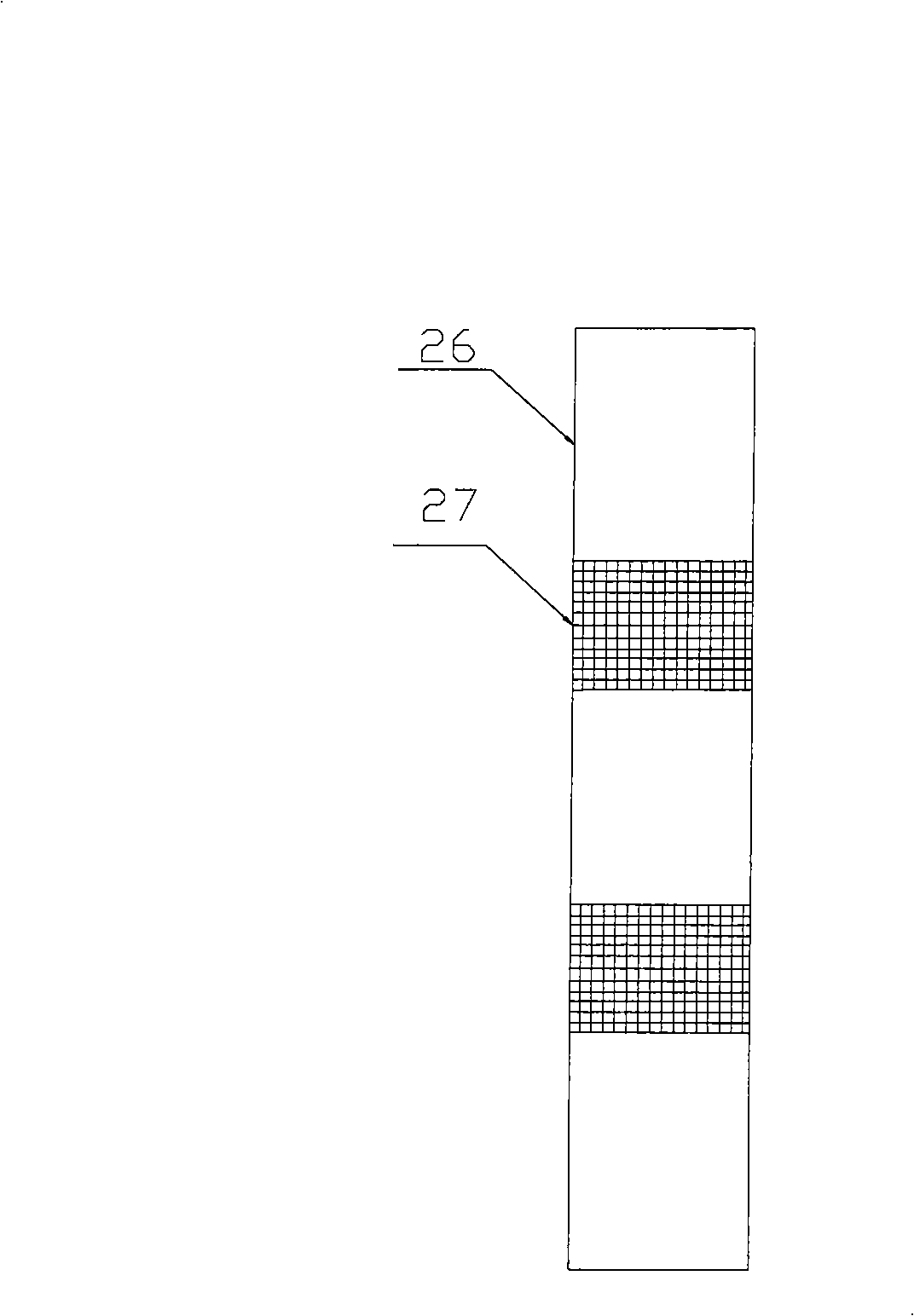

[0094] The acid production reactor 8 in the device of this embodiment uses a filter bed reactor provided with a filter layer 17, and the filter bed reactor is provided with an agitator 9, a third sprayer 25 and a heating and temperature control device. The acid-generating discharge port 10 is arranged above the filter layer 17, the acid-generating liquid discharge port 28 is arranged below the filter layer 17, and the methanogenic reactor 11 is also provided with a liquid output port 12, the liquid output port 12 is connected to the third sprayer 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com