Production method for full-dull nylon 6-slice

A manufacturing method and full extinction technology, which is applied in the manufacture of rayon, textiles and paper, and single-component polyamide rayon. It can solve the problem of light fastness, weakening of heat resistance and oxidation resistance, and easy occurrence of color difference and stripes on the cloth surface. , low dyeing rate and other problems, to achieve the effect of good matting performance, good spinning performance and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Select titanium dioxide coated with anatase grade average particle size D50m=0.31 μm inorganic manganese ions, add water to prepare a suspension with a concentration of 28%, add 0.3wt% sodium hexametaphosphate dispersant relative to the weight of titanium dioxide, and then grind Machine grinding for 5 hours, put it into the sedimentation tank for 24 hours, put the upper suspension into the titanium dioxide blending tank through the filter, measure the concentration of the titanium dioxide suspension, use caprolactam solution to correct the concentration of the titanium dioxide suspension, so that the titanium dioxide reaches the relative weight It is a standard matting agent solution with a concentration of 20%.

[0024] A certain weight of molten caprolactam solution, water as an initiator of 3.5wt% relative to the weight of caprolactam, 0.1wt% acetic acid, and 7.5wt% titanium dioxide solution, that is, the content of titanium dioxide relative to the weight of caprolact...

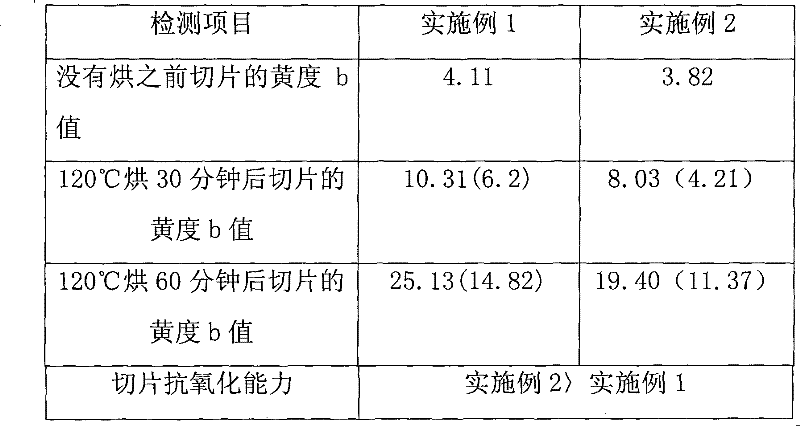

Embodiment 2

[0026] The preparation of the titanium dioxide solution was the same as in Example 1.

[0027] A certain weight of caprolactam, water as initiator of 3.5wt% relative to the weight of caprolactam, 7.5wt% titanium dioxide solution, i.e. 1.5% titanium dioxide content relative to the weight of caprolactam, 0.4wt% terephthalic acid, 0.3wt% Dipiperidinyl isophthalamide, 0.1wt% of 3-(diethylamino)-1-propylamine are metered by a metering pump, then mixed by a static mixer and continuously sent into the VK polymerization tube. A stirrer is installed on the upper part of the polymerization tower, and the stirring speed is 130 rpm, so that the caprolactam solution and the titanium dioxide solution are further mixed evenly during the reaction process, and the agglomeration and sedimentation of the titanium dioxide in the polymerization reaction are prevented. Under the conditions of the upper polymerization temperature of 260-270°C and the lower polymerization temperature of 240-250°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com