Aromatization method without hydrogen for light hydrocarbon

An aromatization and non-hydrogenation technology, which is used in the production of aromatic hydrocarbons or clean gasoline components and the production of high-quality liquefied gas. The effect of increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0058] (1) Preparation of composite carrier

[0059] Take 67.6 kg of pseudo-boehmite powder (produced by Sasol Company, SB, alumina content 74 mass %), under stirring conditions, added to 300 kg of nitric acid aqueous solution with a concentration of 1.1 mass %, after stirring for 2 hours to peptize, add 55.0 kg of silica / alumina molar ratio of 60 HZSM- 5 Zeolite powder (91% zeolite content), stirring at high speed for 3 hours. The prepared slurry was dropped into an oil-ammonia column containing 8% by mass of ammonia water, and the wet bulb formed in the oil-ammonia column was taken out, dried at 60° C. for 10 hours, and calcined at 550° C. for 3 hours to obtain a composite carrier containing HZSM- 5 zeolite 50 mass % alumina pellets.

[0060] (2) Preparation of catalyst

[0061] Take 50 kilograms of composite carrier, use 50 kilograms containing 4.7% by mass of zinc nitrate, 3.0% by mass of chlorinated mixed rare earth (31% of lanthanum oxide, 51% of cerium oxide, 14% of...

example 2

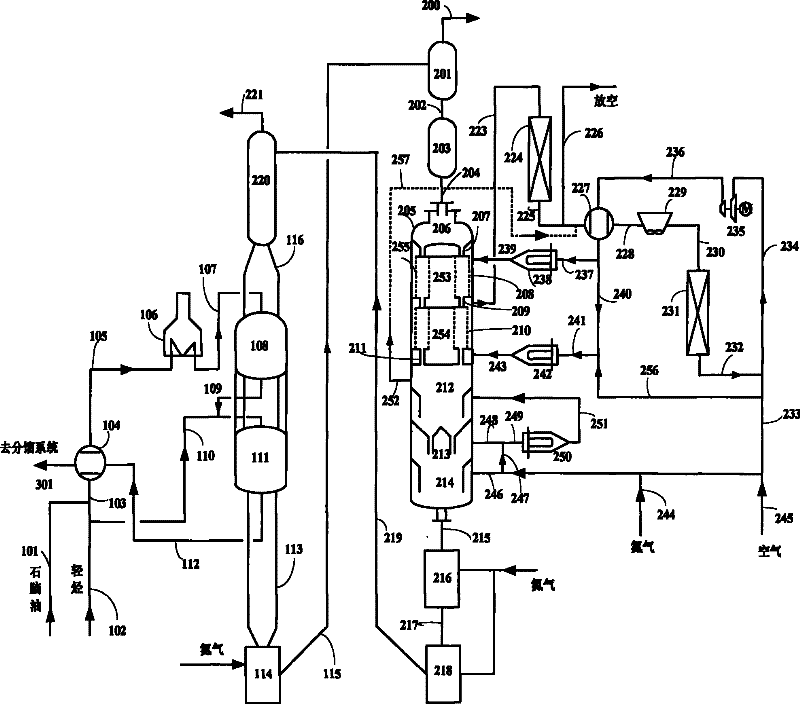

[0064] according to figure 1 Shown in the process flow, using the catalyst prepared in Example 1, with 60 mass % of the straight-run naphtha shown in Table 1 and 40 mass % of the light hydrocarbons shown in Table 2 as raw materials to carry out the aromatization reaction test, the reaction is in It is carried out under non-hydrogen conditions. The raw material inlet temperature of each reactor was controlled to be 400 °C, the reaction pressure was 0.5 MPa, and the mass space velocity of the raw material was 0.5 h. -1 . The light hydrocarbons are evenly divided into two strands, one strand is mixed with straight-run naphtha and then enters the first reactor through the heating furnace, and the other strand of light hydrocarbons directly enters the second reactor 111 in the form of cold feed. The pressure of the regenerator is 0.7MPa, the inlet temperature of the regeneration gas in the first-stage coking zone is 470°C, and the oxygen content is 0.5% by volume; the inlet tempe...

example 3

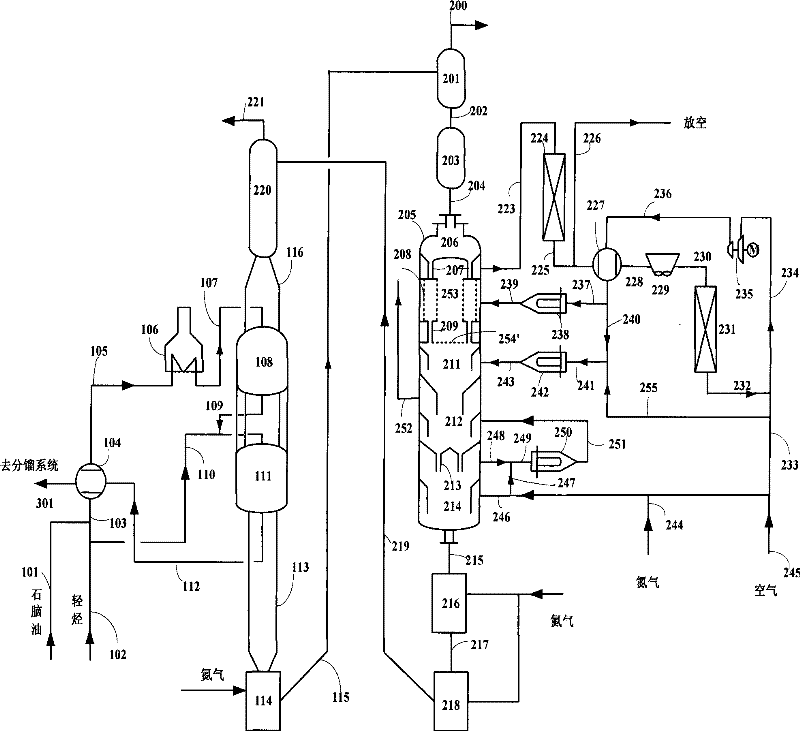

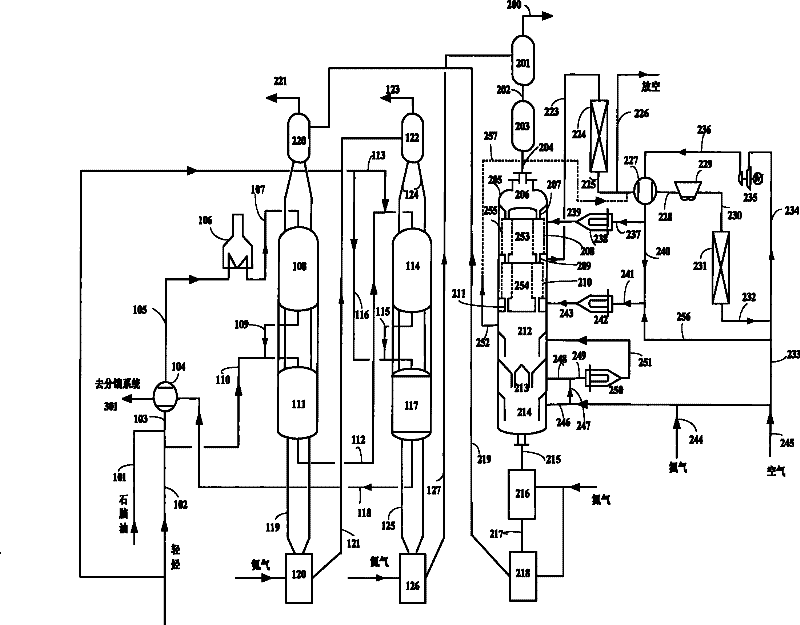

[0066] according to figure 2The shown process flow, using catalyst A, with 60% by mass of straight-run naphtha shown in Table 1 and 40% by mass of the light hydrocarbons shown in Table 2 as raw materials to carry out the aromatization reaction test, the reaction is non-hydrogenated. conditions. The operating conditions of the reaction part and the regenerator, the residence time of the catalyst to be produced in the coking zone, and the temperatures in the drying zone and the cooling zone are the same as those in Example 2, except that the regeneration gas enters the two-stage coking zone from the middle. The test results are shown in table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com