Zr-Cu-Ni-Al-Ag alloy with higher amorphous forming ability and production method thereof

A zr-cu-ni-al-ag, amorphous technology is applied in the field of preparation of Zr-based amorphous alloys to achieve the effects of improving amorphous forming ability, good application prospect and strong amorphous forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

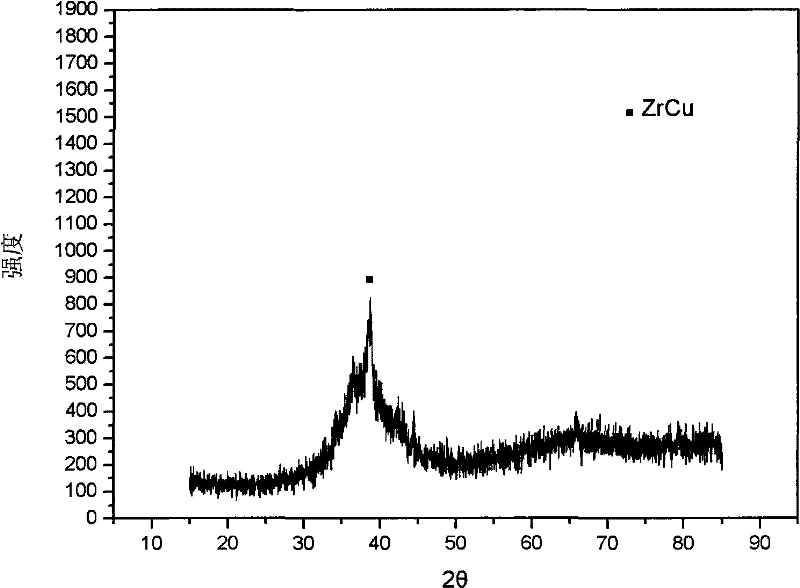

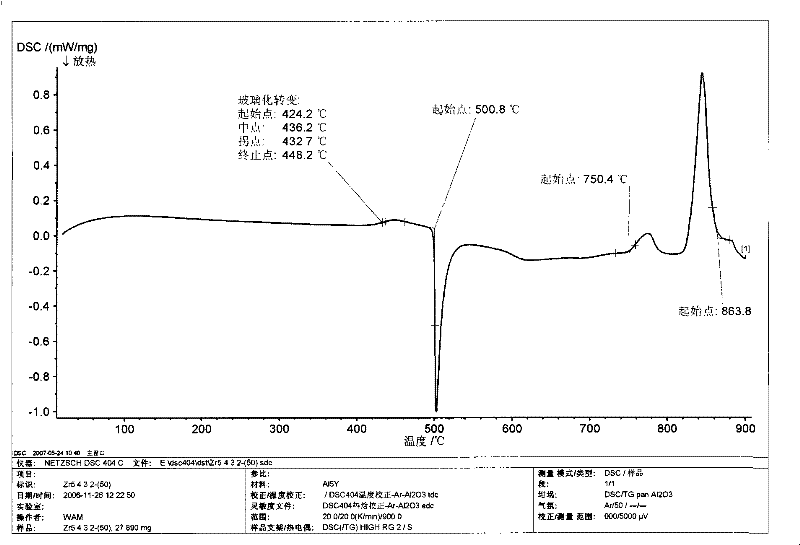

[0036] The raw materials used in this example are all high-purity (>99.9%) pure metals, and the master alloy ingots are prepared by arc melting under the protection of argon. In order to ensure that the composition of the alloy ingots is uniform, the alloy ingots are smelted at least four times . By inhibiting the ZrCu phase, the amorphous formation ability of the alloy is very effectively improved. The specific composition of the alloy is (atomic percentage): 51% Zr, 29.9% Cu, 5% Ni, 11% Al, 3.1% Ag.

[0037] Under high vacuum conditions, through vacuum spray casting equipment, the master alloy ingots are remelted and blown into Cu molds of different sizes with argon. The present embodiment adopts copper mold casting concrete process parameter as follows: vacuum degree 10 -3 Pa, temperature 1200°C, cooling rate 10 2 K / s.

[0038] Such as figure 2 As shown, even if the alloy rod with a diameter up to 20 mm is spray-cast, the XRD results show that the rod is completely amo...

Embodiment 2

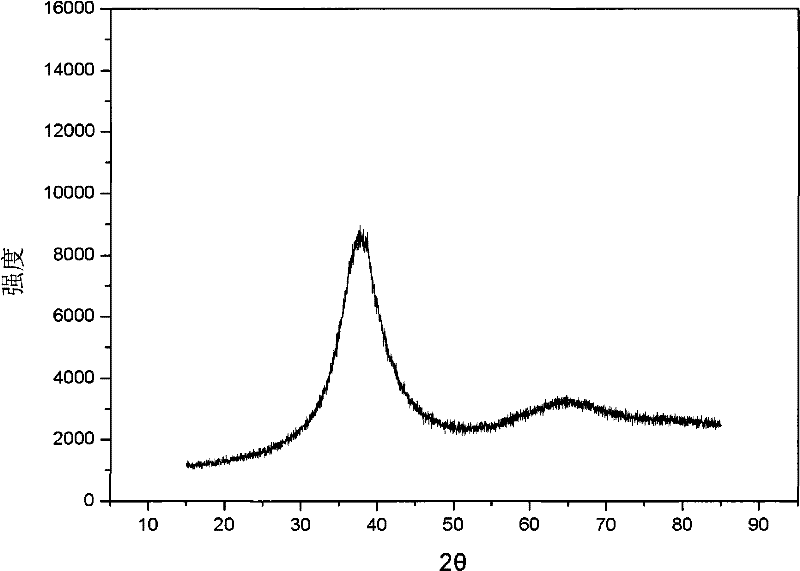

[0043]The raw materials used in this example are all high-purity (>99.9%) pure metals, and the master alloy ingots are prepared by arc melting under the protection of argon. In order to ensure that the composition of the alloy ingots is uniform, the alloy ingots are smelted at least four times . By inhibiting the ZrCu phase, the amorphous formation ability of the alloy is very effectively improved. The specific composition of the alloy is (atomic percentage): 53% Zr, 32% Cu, 4% Ni, 9% Al, 2% Ag.

[0044] Under high vacuum conditions, through vacuum spray casting equipment, the master alloy ingots are remelted and blown into Cu molds of different sizes with argon. The present embodiment adopts copper mold casting concrete process parameter as follows: vacuum degree 10 -3 Pa, temperature 1360°C, cooling rate 10 2 K / s.

[0045] An alloy round rod with a diameter of up to 18 mm was spray-cast, and the XRD result showed that the round rod was amorphous (such as Figure 5 shown)...

Embodiment 3

[0050] The raw materials used in this example are all high-purity (>99.9%) pure metals, and the master alloy ingots are prepared by arc melting under the protection of argon. In order to ensure that the composition of the alloy ingots is uniform, the alloy ingots are smelted at least four times . By inhibiting the ZrCu phase, the amorphous formation ability of the alloy is very effectively improved. The specific composition of the alloy is (atomic percentage): 53% Zr, 22.5% Cu, 4.5% Ni, 9% Al, 11% Ag.

[0051] Under high vacuum conditions, through vacuum spray casting equipment, the master alloy ingots are remelted and blown into Cu molds of different sizes with argon. The present embodiment adopts copper mold casting concrete process parameter as follows: vacuum degree 10 -3 Pa, temperature 1280°C, cooling rate 10 2 K / s.

[0052] An alloy round rod with a diameter of up to 20mm was spray-cast, and the XRD result showed that the round rod was amorphous (such as Figure 8 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com