Double clutch hybrid power machine AMT speed-changer executing mechanism and control method

A hybrid vehicle and actuator technology, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, general power units, and motor vehicles, etc., can solve the problem of slow motor speed, inability to select the gear of the transmission, and reduced power performance. and other problems, to achieve the effect of fewer parts, improved joints, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] For ease of explanation, the relevant terms are first explained as follows:

[0040] A hybrid vehicle generally refers to a vehicle driven by an electric motor as an auxiliary power of the engine, which has high fuel economy performance and superior driving performance.

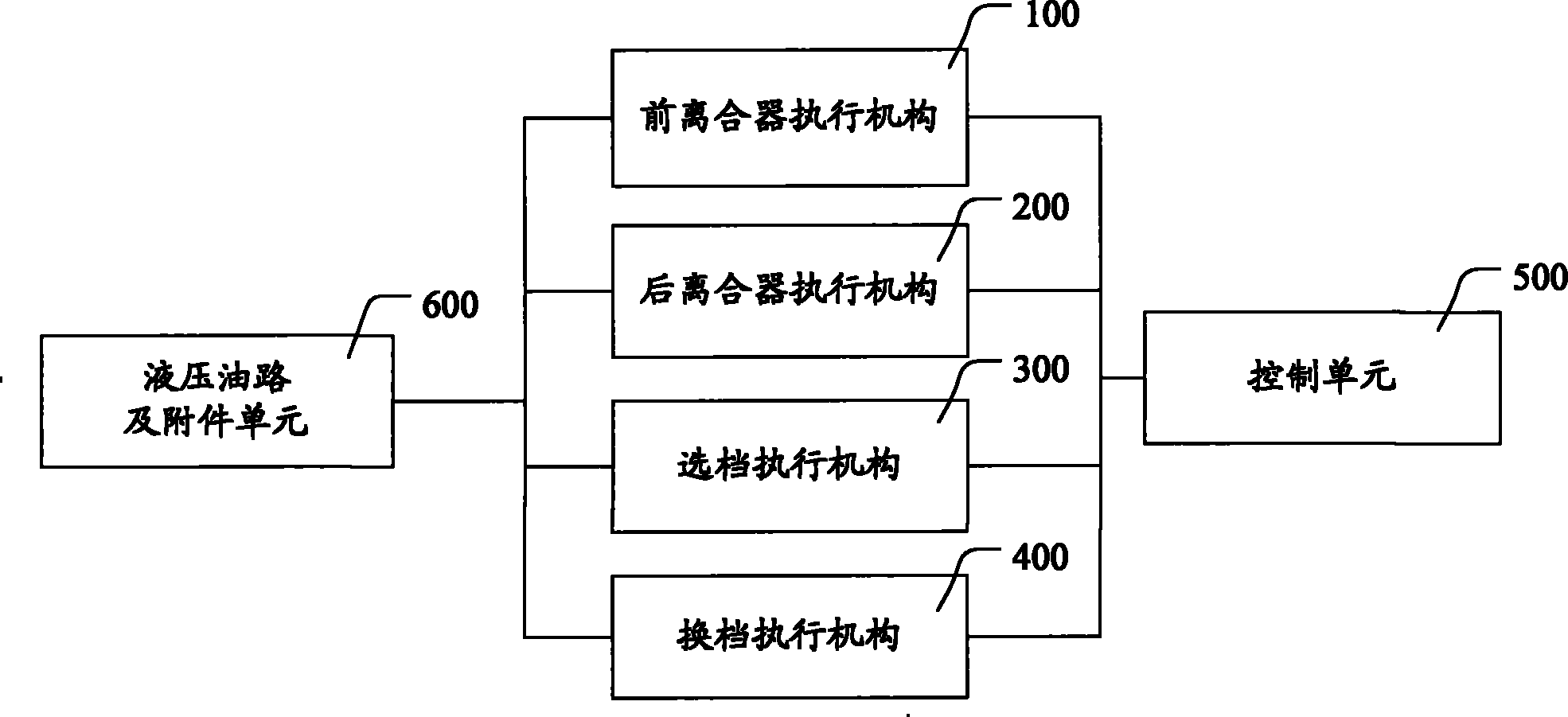

[0041] The power system of a hybrid electric vehicle is mainly composed of a control system, a drive system, an auxiliary power system and a battery pack. Due to the existence of the battery pack, the engine works in a relatively stable working condition, and its emission is improved.

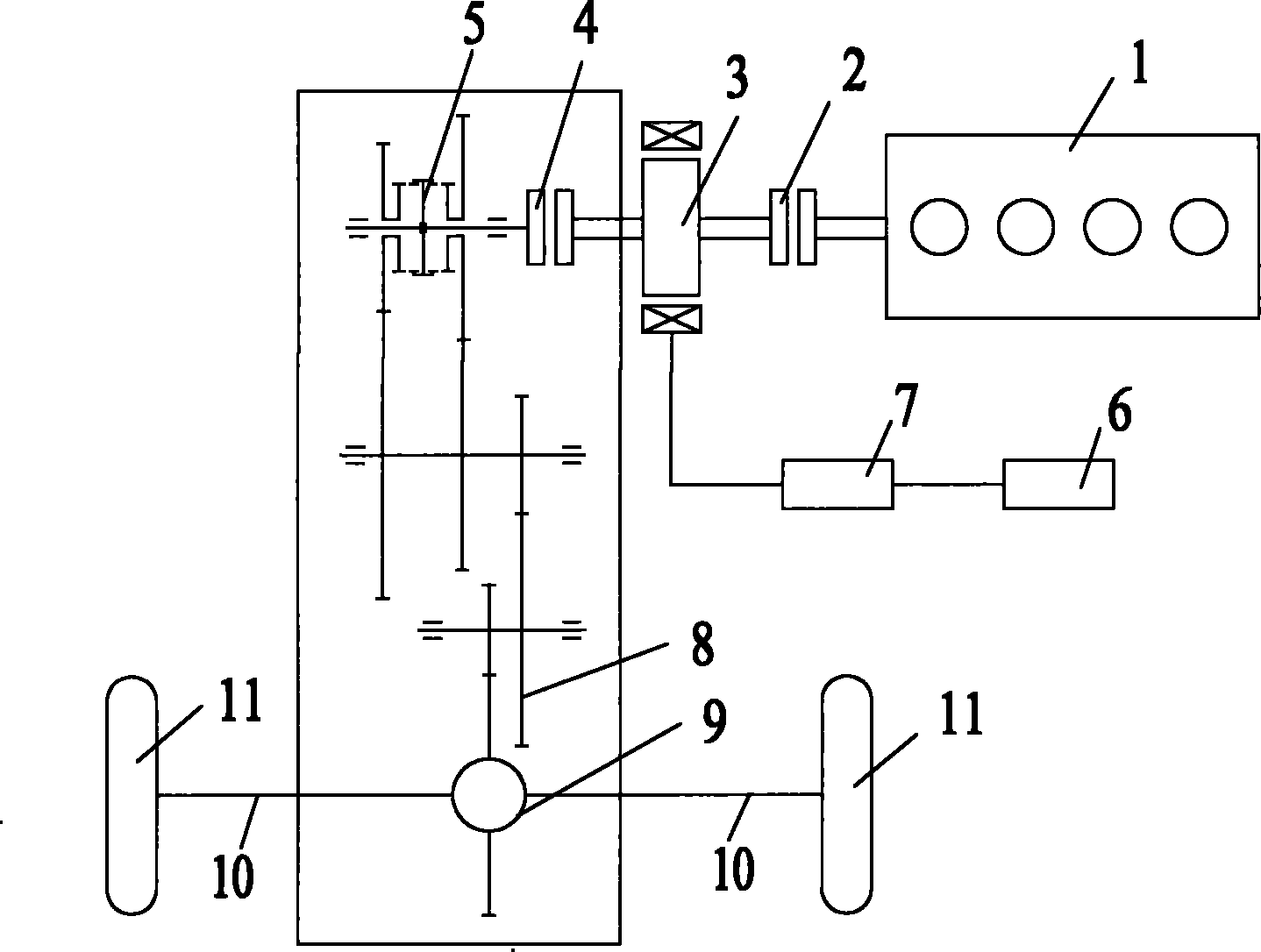

[0042] The transmission system of a hybrid electric vehicle refers to the device in a hybrid electric vehicle that is responsible for transmitting power so that the vehicle can perform its driving function. At present, according to the classification of power transmission route, it can be divided into three types: series type, parallel type and hybrid type.

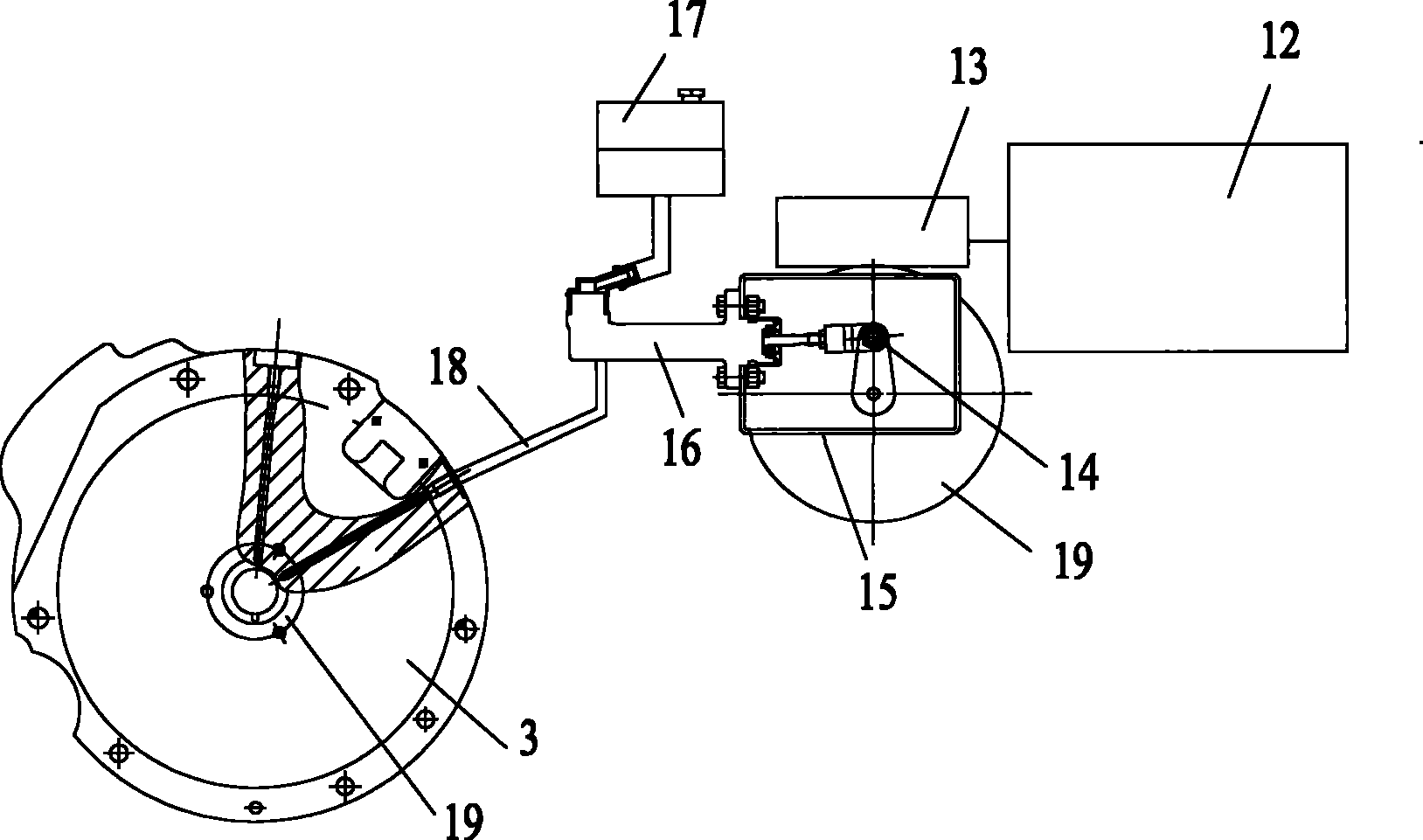

[0043] Dual clutch means that there are two front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com