Preparation of acetoxylsilane

A technology of acetoxysilane and organochlorosilane, applied in the field of preparation of acetoxysilane, can solve the problems of high chloride ion content, high production cost, affecting the storage of finished silicone rubber products, etc., and achieves high purity and low cost. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

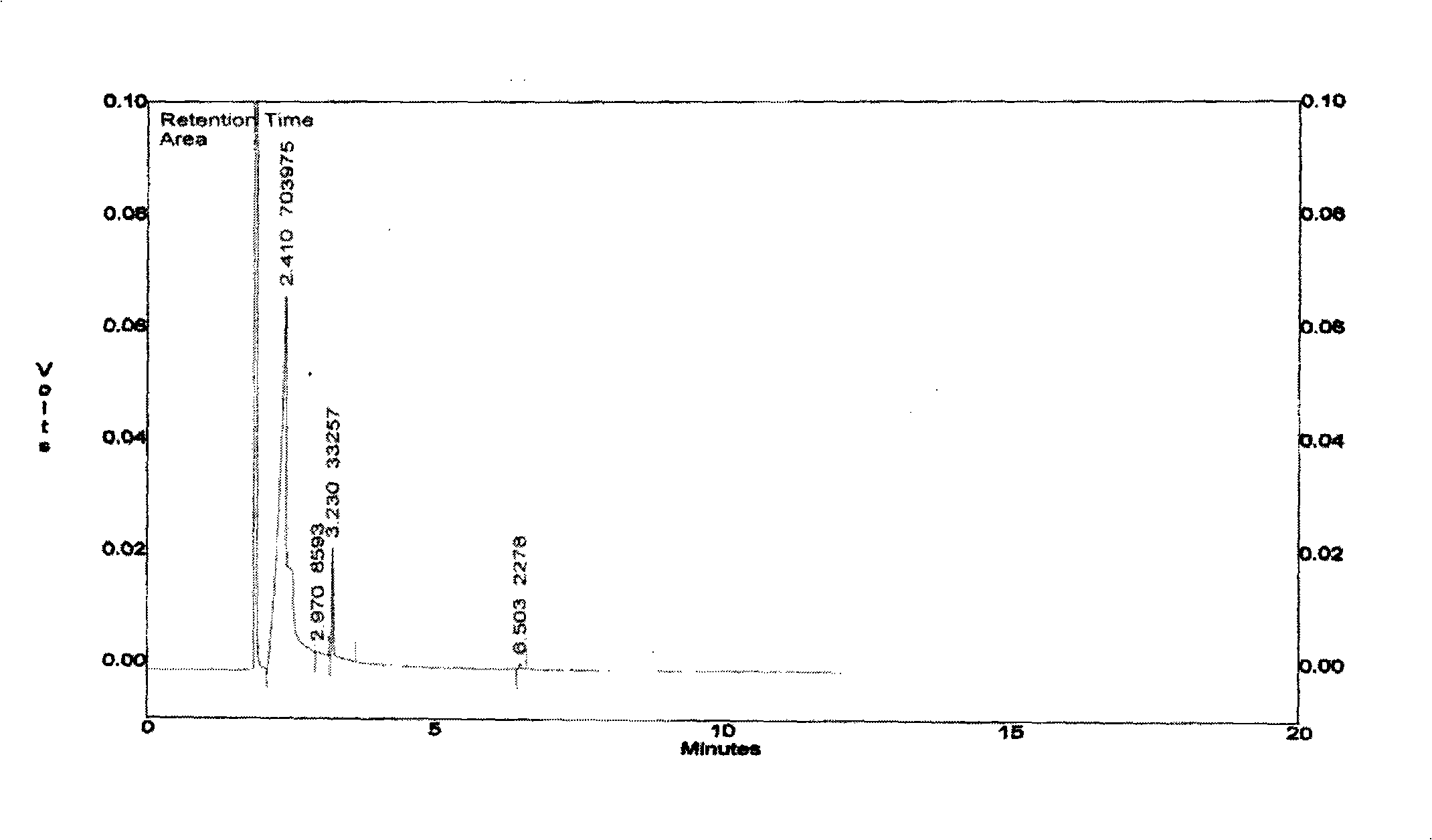

[0013] Example 1: Preparation of methyltriacetoxysilane. Add 1mol methyltrichlorosilane and 150ml solvent gasoline into the reaction vessel (such as a four-necked flask with a thermometer, condenser, stirring, constant pressure cylindrical funnel and cylindrical packing tower), under stirring conditions, the above liquid After gradually increasing the temperature to boiling, start to add 3.3 mol of acetic acid to react with methyl trichlorosilane, and the boiling reaction is 8 hours to obtain the methyl triacetoxy silane solution. At the same time, the HCl gas is collected during the reaction to obtain the by-product hydrochloric acid; Control the temperature at 100-110℃, and recover the solvent gasoline in the acetoxysilane solution by distillation under normal pressure. After the solvent gasoline recovery rate reaches 93%, keep the temperature at 110℃, and distill under reduced pressure to remove the residual low boilers in the reaction vessel. , Until there is no distillate, a ...

Embodiment 2

[0014] Example 2: Preparation of ethyltriacetoxysilane. Add 1 mol of ethyl trichlorosilane and 160 ml of solvent gasoline into the reaction vessel. Under stirring conditions, the above liquid is gradually heated to boiling, then 3.1 mol of acetic acid is added dropwise to react with ethyl trichlorosilane, and the boiling reaction is carried out for 8 hours. Obtain the methyl triacetoxysilane solution, and collect HCl gas during the reaction to obtain the by-product hydrochloric acid; then control the temperature at 100-110°C and distill at atmospheric pressure to recover the solvent gasoline. After the solvent gasoline recovery rate reaches 93%, the The temperature is maintained at 110° C., and the low boilers remaining in the reaction vessel are removed by distillation under reduced pressure until there is no distillate to obtain a colorless and transparent product. Analysis by gas chromatograph shows that the effective content of ethyltriacetoxysilane in the product is ≥94%.

Embodiment 3

[0015] Example 3: Preparation of vinyl triacetoxysilane. Add 1 mol vinyltrichlorosilane and 180ml solvent gasoline into the reaction vessel. Under stirring conditions, the above liquid is gradually heated to boiling, then 3.2mol acetic acid is added dropwise to react with vinyltrichlorosilane, and the reaction is boiling for 8 hours Obtain methyltriacetoxysilane solution, and collect HCl gas during the reaction to obtain hydrochloric acid as a by-product; then control the temperature at 100-110°C and distill at atmospheric pressure to recover solvent gasoline. After the solvent gasoline recovery rate reaches 93%, The temperature is maintained at 110° C., and the low boilers remaining in the reaction vessel are removed by distillation under reduced pressure until there is no distillate to obtain a colorless and transparent product. Analysis by gas chromatograph shows that the effective content of vinyltriacetoxysilane in the product is ≥93%.

[0016] In the above embodiments, solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com